Synchronous servo electric spindle of precision numerical control machine tool

A precision numerical control and servo electric technology, applied in the direction of electromechanical devices, control mechanical energy, electrical components, etc., can solve the problems of large rotor power consumption, heat generation, loss of rotation, and large vibration, so as to facilitate turning processing, reduce thermal errors, and work. The effect of low heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

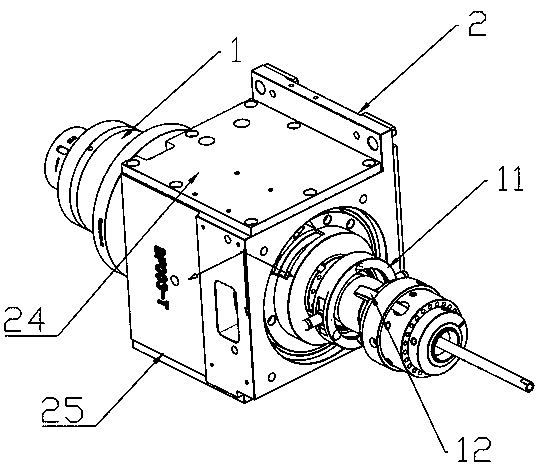

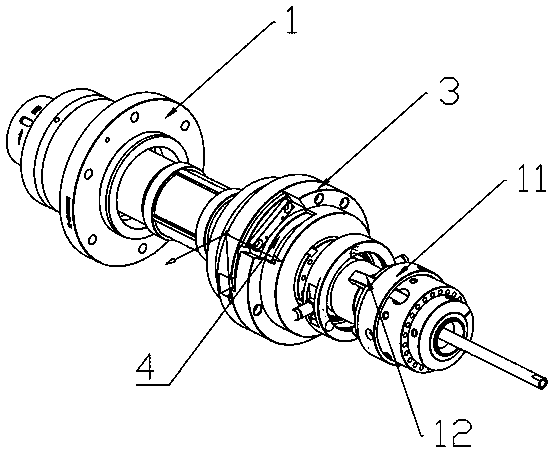

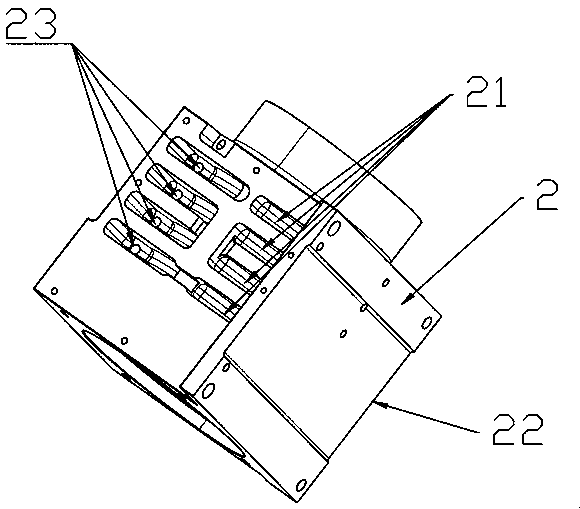

[0020] Such as Figure 1 to Figure 4 The synchronous servo electric spindle 1 of a precision numerical control machine tool shown includes a spindle 1, a sleeve casting 2, a stator 3 and a permanent magnet rare-earth rotor 4. There is an installation chamber inside the sleeve casting 2, and the stator 3 is installed on The installation chamber, the main shaft 1 is set in the stator 3, and the permanent magnet rare earth rotor 4 is fixedly arranged on the shaft body of the main shaft 1, and drives the main shaft 1 to rotate under the action of magnetic force; the stator and the rotor of the present invention are made of permanent magnetic rare earth materials , and the use of the output mode of the synchronous motor makes the overall volume of the synchronous servo electric spindle 1 small, the stator and rotor of the motor ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com