Heavy type part hydraulic clamping and welding positioner

A welding positioner and hydraulic clamping technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity and low efficiency of robot welding, and improve welding efficiency, Prevents entanglement and oil leakage and reduces labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

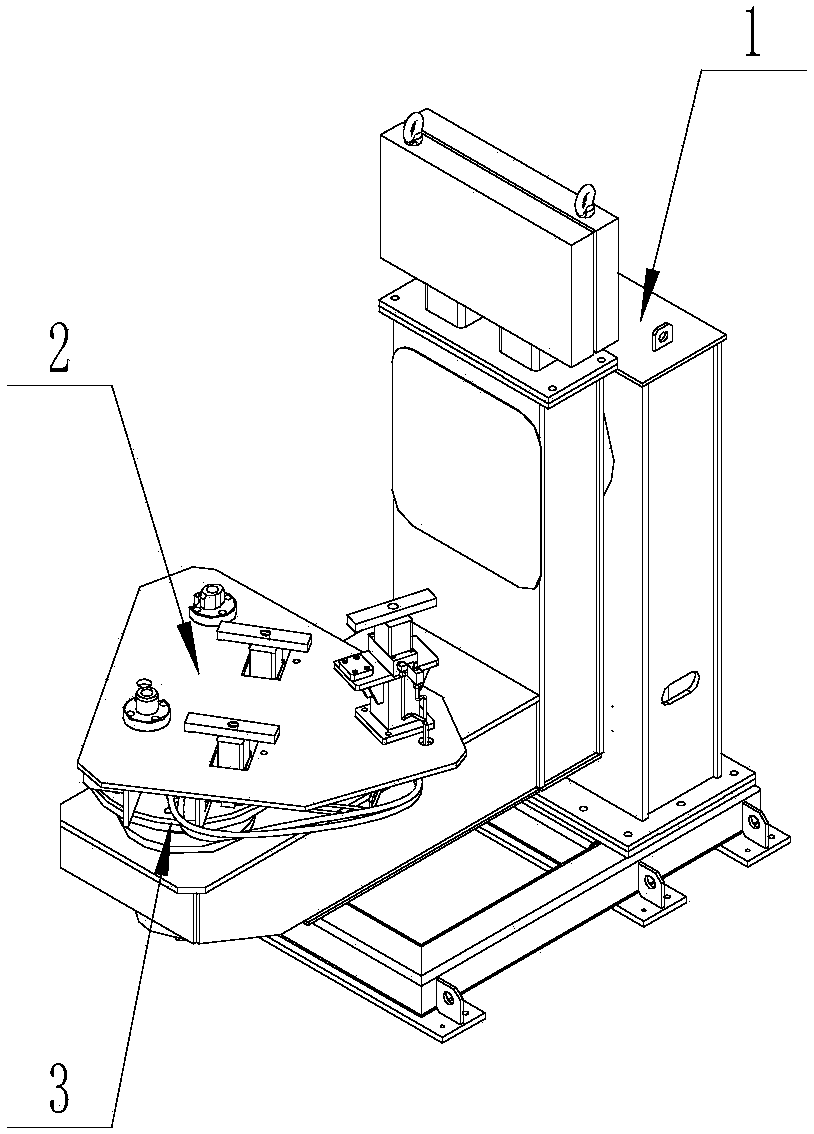

[0023] Such as figure 1 As shown, a hydraulic clamping welding positioner for heavy parts proposed by the present invention includes a main structure 1 of an L-shaped welding positioner, a clamping body 2 and a transmission mechanism 3 .

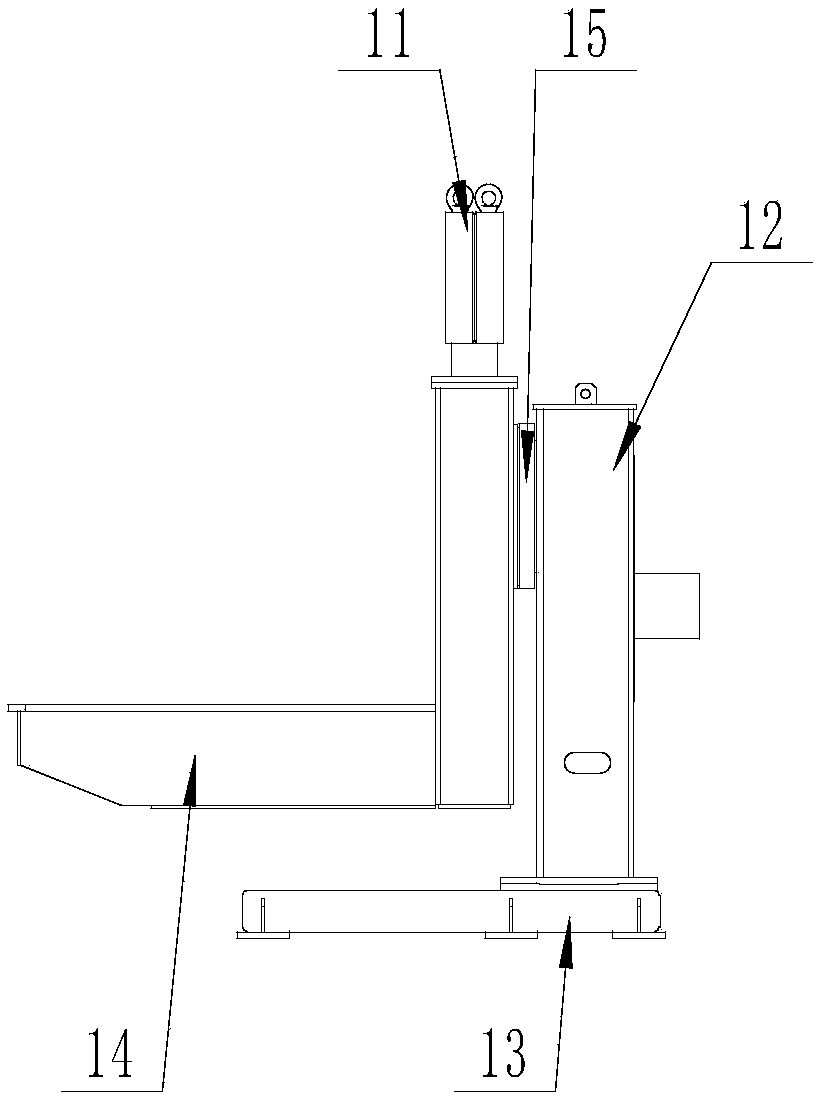

[0024] Such as figure 2 As shown, the main structure 1 of the L-shaped welding positioner includes a counterweight body 11, a vertical motor cabinet 12, a positioner base 13, an L-shaped arm 14 and a rotary mechanism 15, and the counterweight body 11 is fixed on the L-shaped arm 14 by bolts , the L-shaped arm 14 is connected with the vertical motor cabinet 12 through the slewing mechanism 15, which can realize ±180 ° flipping on the vertical plane, and the vertical motor cabinet 12 is fixed on the positioner base 13 by bolts.

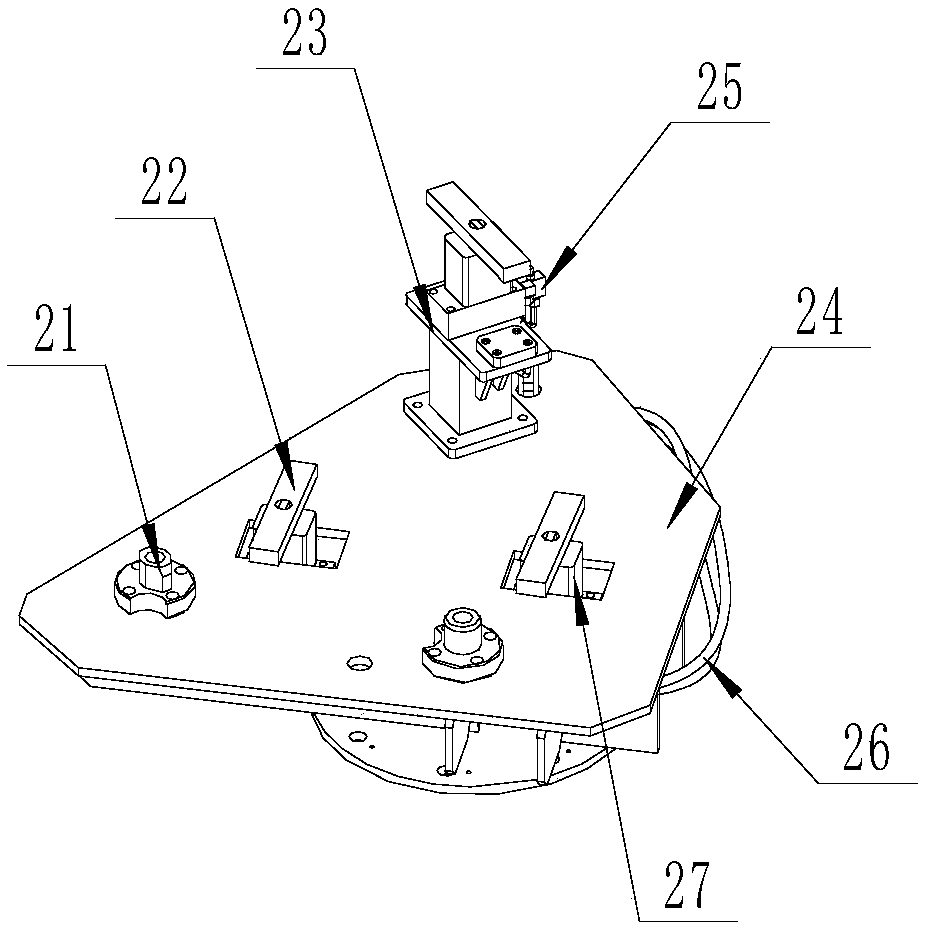

[0025] Such as image 3 As shown, the clamp body 2 includes a positioning shaft 21, a pressing block 22, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com