Six-part full-automatic assembly machine for invisible zipper puller

An invisible zipper, fully automatic technology, applied in the direction of fasteners, sliding fastener components, applications, etc., can solve the problem of difficulty in distinguishing the slider, whether the hook assembly holes are aligned in a straight line, the copper pin cannot enter the hole smoothly, and the slider is difficult to distinguish. , the pull tab is easy to swing, etc., to achieve the effect of saving manpower and material resources, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

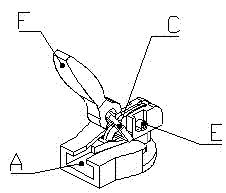

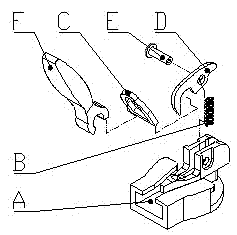

[0031] Such as figure 1 , figure 2 As shown, the six-piece invisible zipper puller of the present invention includes the base body of the zipper puller, that is, the slider A, the vertical hole of the slider A is equipped with a zipper puller spring B, and the slender groove of the slider A is embedded with a horse hook D , and the round hole of the horse hook D is aligned with the horizontal hole of the slider A, and a copper pin E is inserted inside. The space formed by the horse hook D and the slider A is covered with a triangular ferrule C, and a pull tab is dropped on the triangular ferrule C. F.

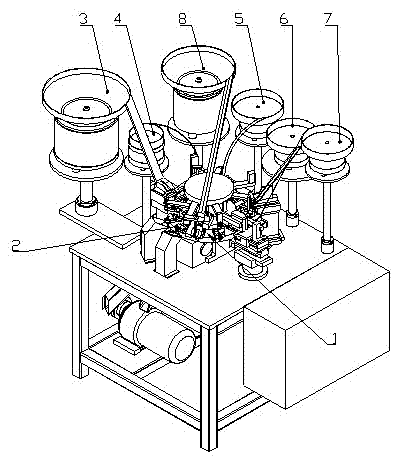

[0032] Such as image 3 , Figure 4 As shown, the present invention comprises machine base, is provided with on the table top of machine base and is connected with power device kinematic assembly 1, and the edge of indexing main turntable of kinemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com