Large gear flame surface quenching machine

A technology of surface quenching and large-scale gears, applied in the direction of quenching device, furnace type, heat treatment equipment, etc., can solve the problems of inappropriate large-scale gears and large investment, and achieve the effects of simple control, accurate indexing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

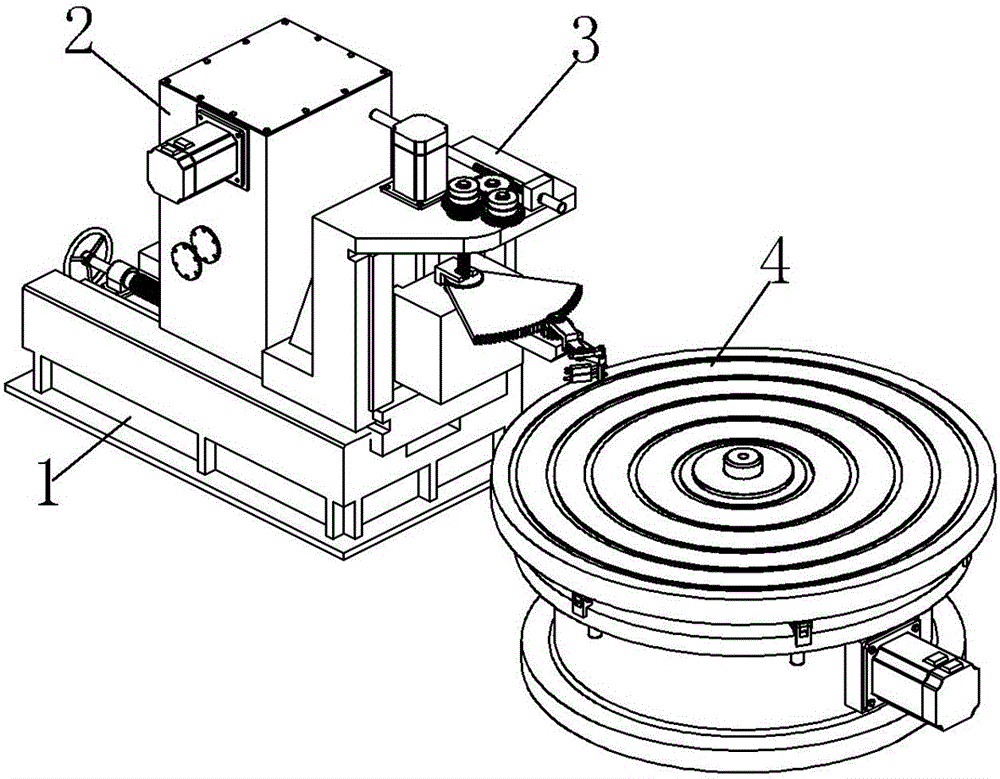

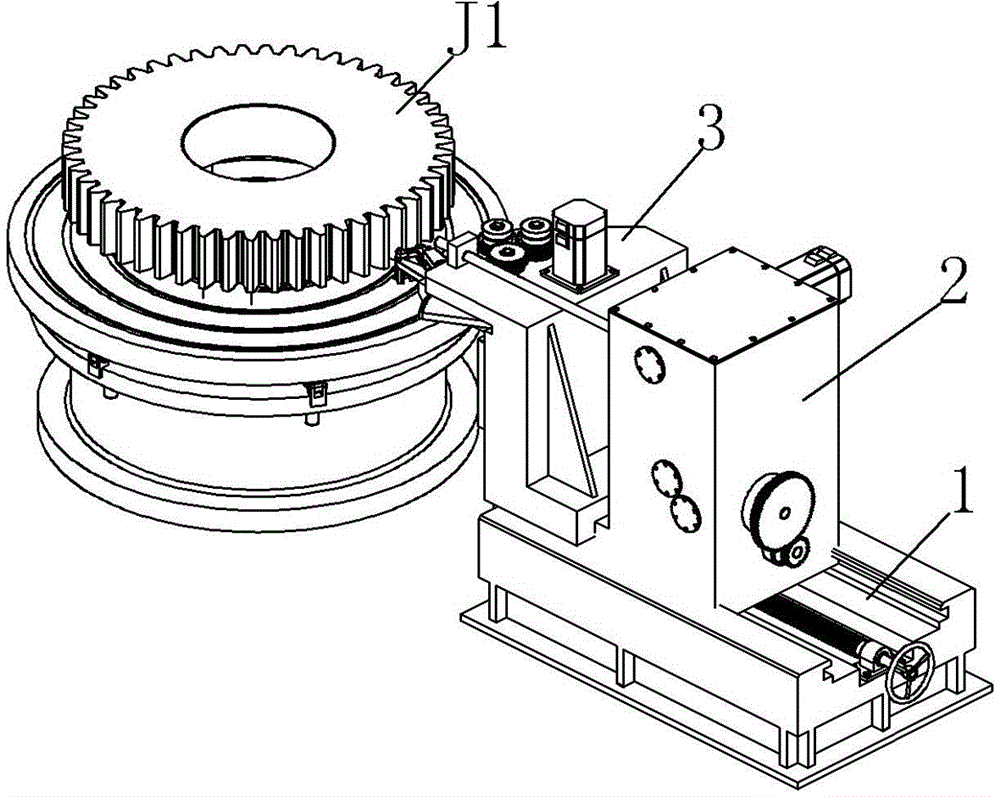

[0025] see figure 1 , 2 As shown, the present invention is composed of a base assembly 1, a transmission device 2, a quenching device 3, and an indexing rotary table 4; the base assembly 1, the transmission device 2 and the quenching device 3 form a combination, and the combination The high-degree rotary table 4 adopts a split structure; the transmission device 2 is arranged on the base assembly 1, and the quenching device 3 is arranged on the transmission device 2.

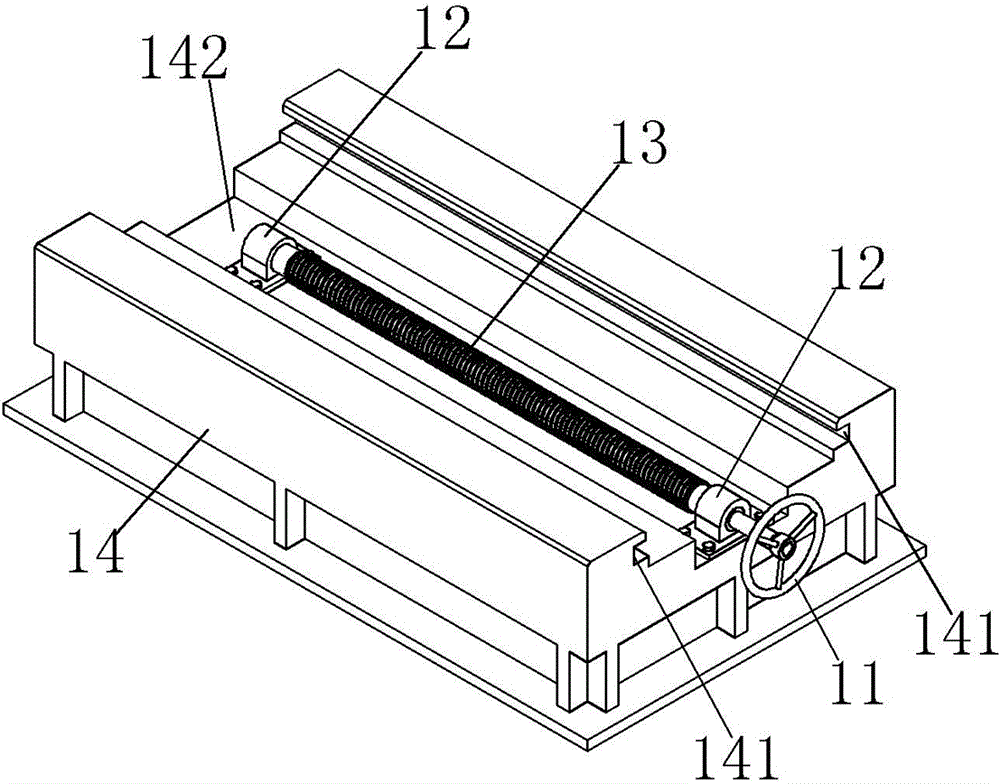

[0026] see figure 1 , image 3 As shown, the base assembly 1 is provided with a hand wheel 11, two bearing housings 12, a horizontal screw 13, and a base 14; two inner rectangular guide rails 141 are arranged on the inner side of the upper part of the base 14, and a rectangular guide rail 141 is arranged in the middle of the upper part. Groove 142; two bearing seats 12 are arranged on the journals at both ends of the horizontal lead screw 13, and the two bearing seats 12 are placed and fixedly connected in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com