Method for processing Sendzimir roll wobbler slot

A plum blossom groove and roll technology, which is applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve problems such as difficult to meet technical requirements for finishing, and achieve the effects of simple structure, guaranteed processing accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

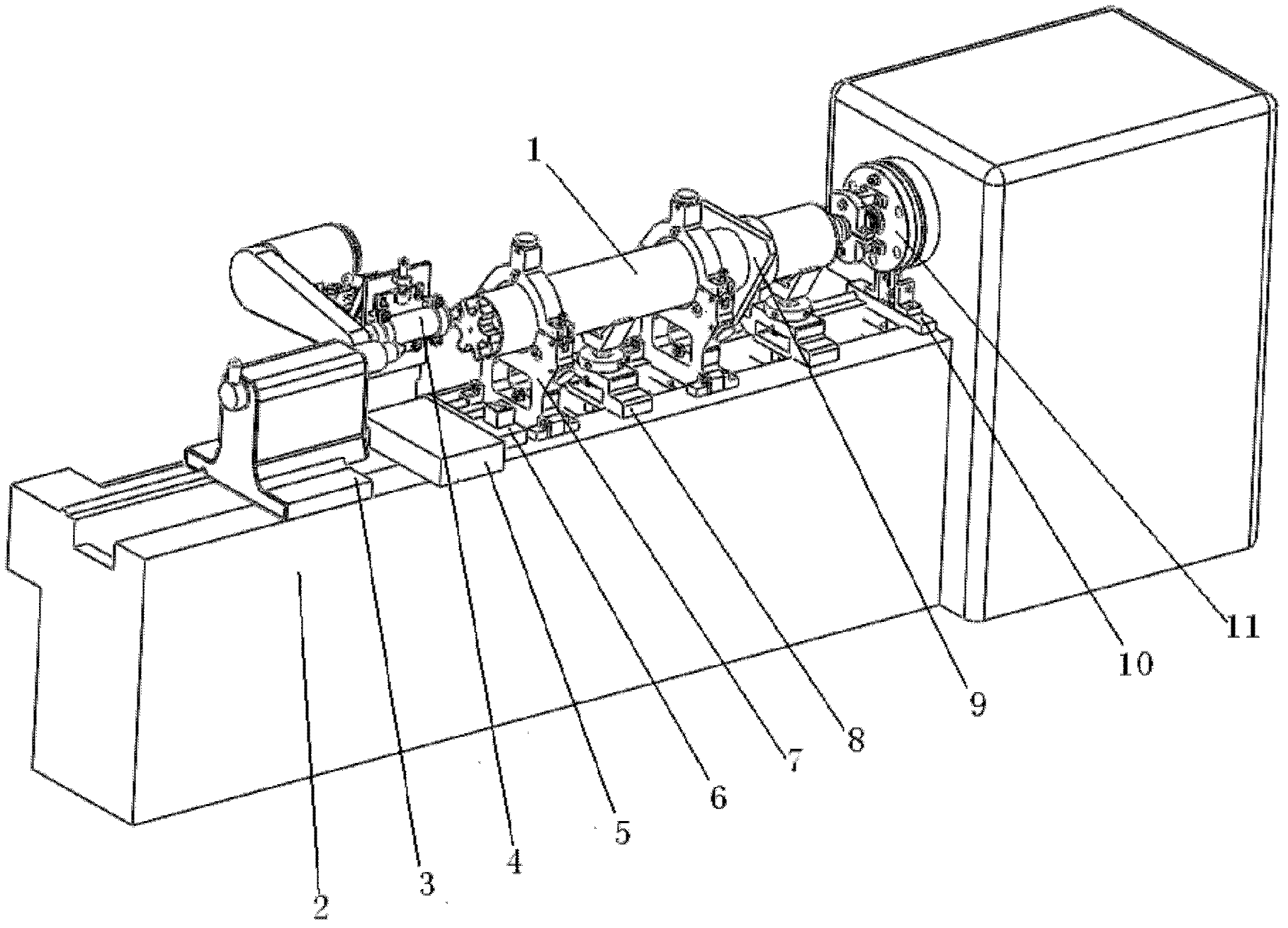

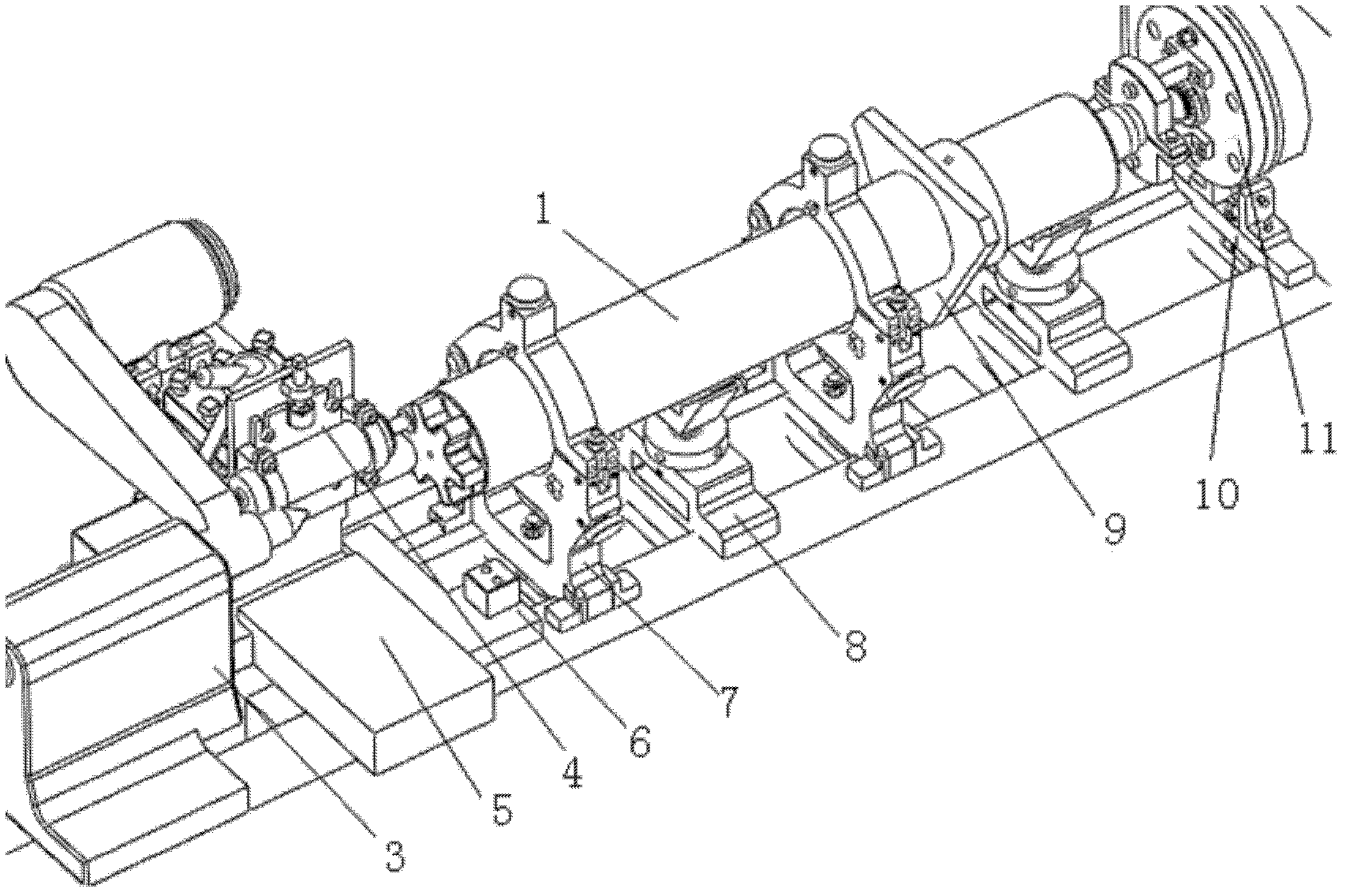

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

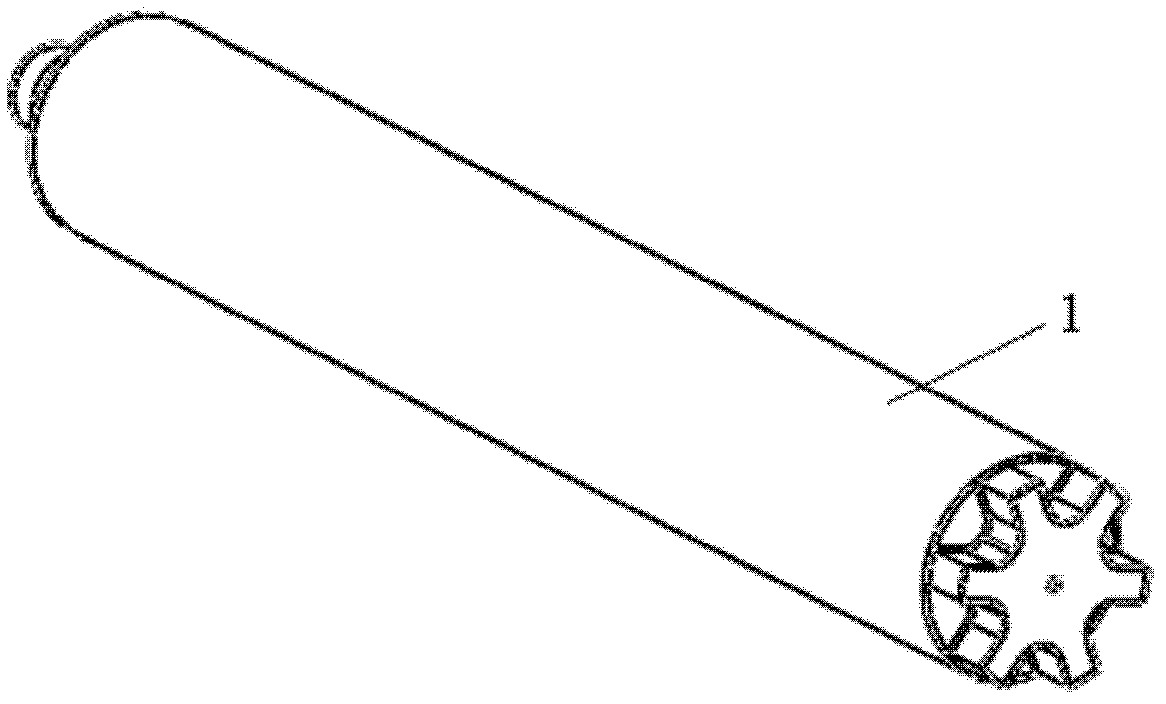

[0029] figure 1 It is a structural schematic diagram of the target workpiece 1 to be finished by the method of the present invention. The workpiece 1 belongs to a transmission roll in a 20-roller Sendzimir rolling mill. Equally divided plum blossom groove, groove shape see Figure 13 , the working surface is two sides of groove tooth thickness 27.4±0.05mm, the indexing accuracy of the working surface is 0.03mm, and the roughness is Ra0.8μm. According to the machining process, the finishing of the plum blossom groove is arranged under the premise that the workpiece 1 has been quenched, the center holes at both ends have been repaired and coaxial, and the outer circle of the roller body has been finely ground. However, because the hardness of the plum blossom groove is as high as HRC56-59 The bit precision is extremely high, the cutting motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com