Indexing and clamping device for numerically-controlled large spiral bevel gear broaching machine

A technology of spiral bevel gears and clamping devices, which is applied in gear tooth manufacturing devices, gear cutting machines, belts/chains/gears, etc., which can solve the problems of frequent indexing movements of indexing mechanisms, reduced indexing accuracy, and short time required and other problems to achieve the effect of realizing processing, eliminating the movement gap, and stabilizing the indexing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

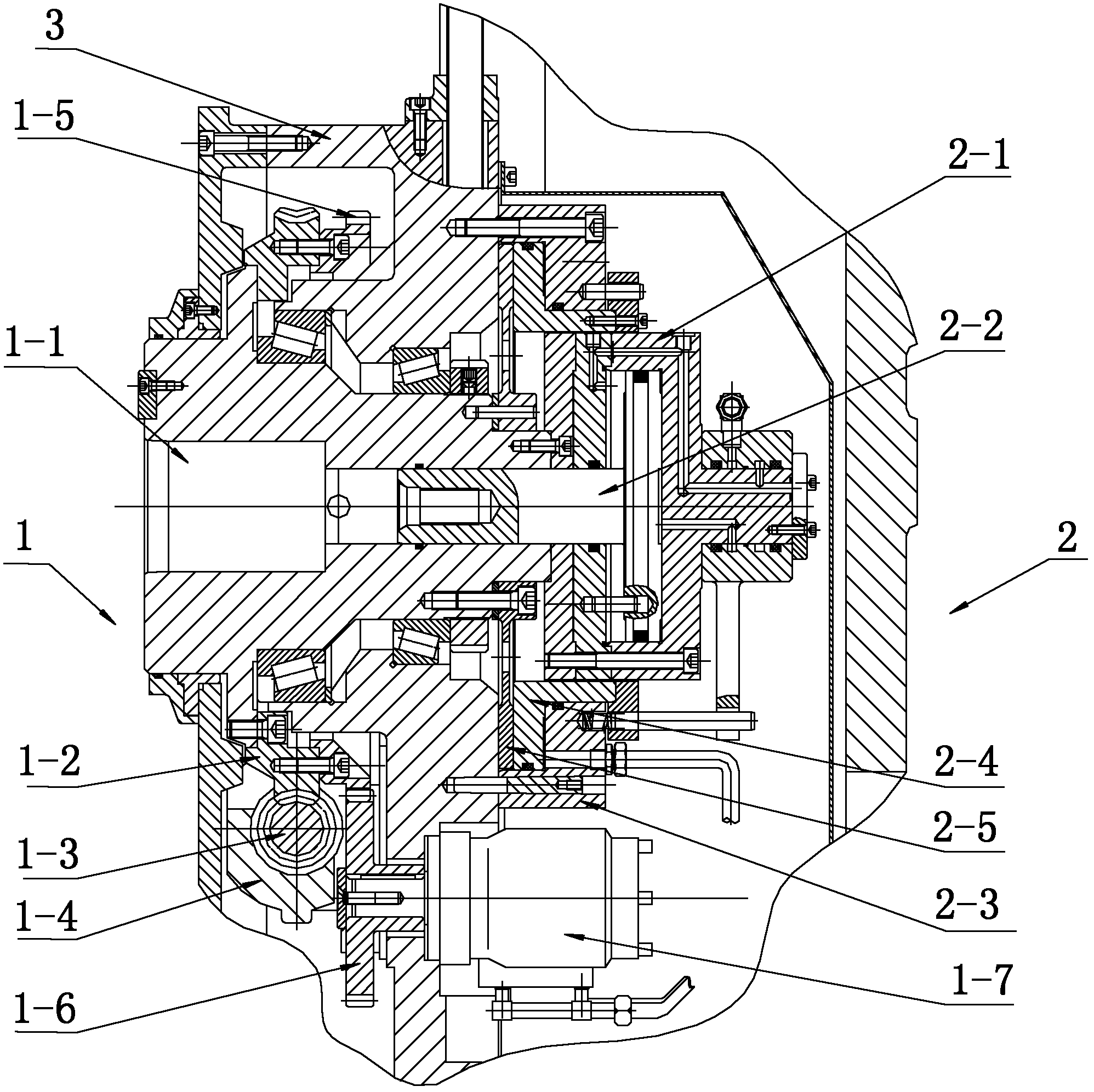

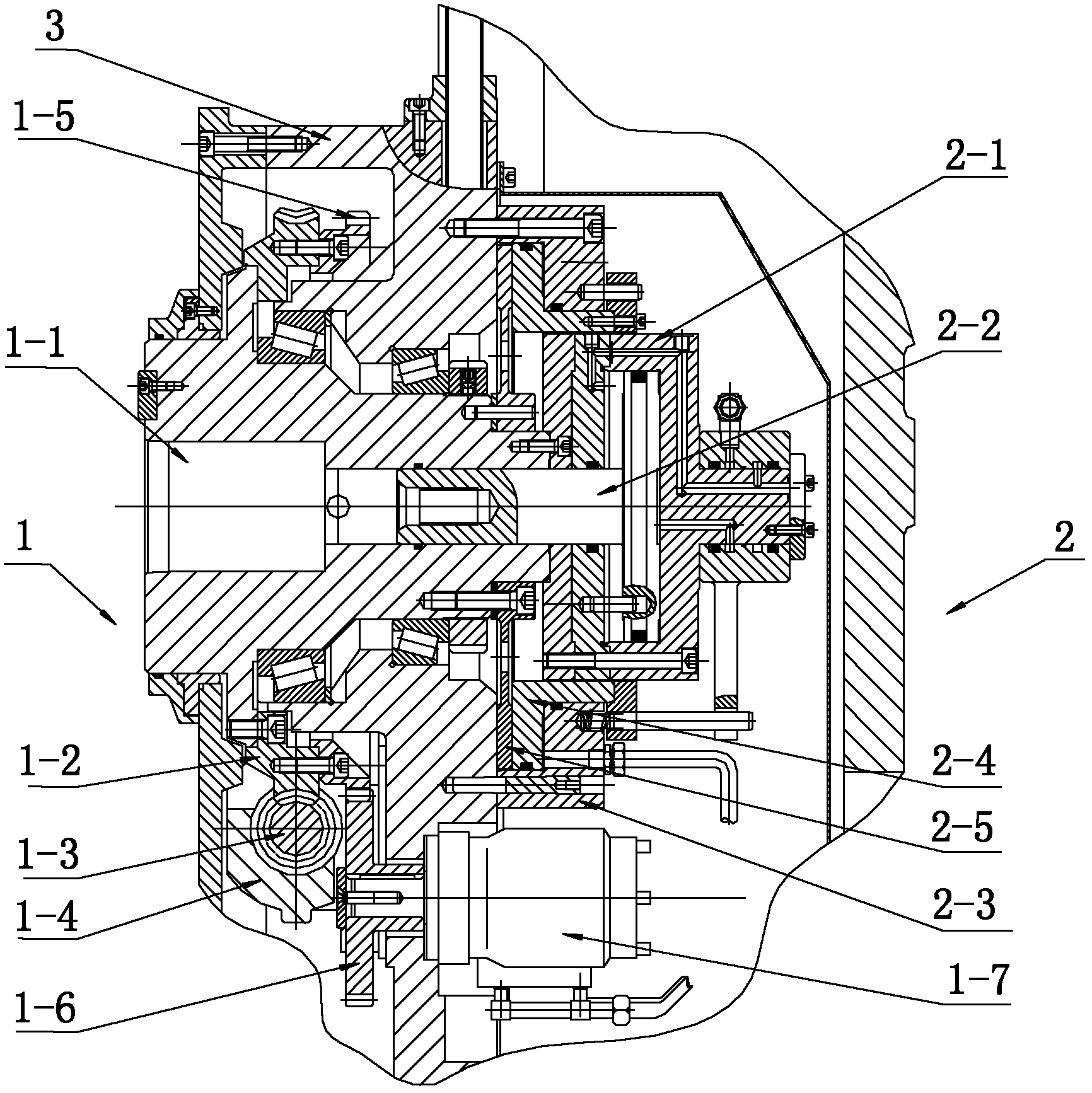

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] see figure 1 , CNC large-scale spiral bevel gear broaching machine indexing and clamping device, including an indexing mechanism 1 driven by a servo motor, the indexing mechanism includes a worm 1-3 connected to the output shaft of the servo motor through a coupling The two ends of the worm are supported and fixed in the worm bracket 1-4 through bearings, and the outer circle of the workpiece main shaft 1-1 is fixed with a worm wheel 1-2 engaged with the worm. On the worm gear 1-2 of the indexing mechanism, a large gear 1-5 is also fixed, and the large gear meshes with the pinion shaft 1-6, and the pinion shaft and the hydraulic motor 1-7 fixed in the spindle housing 3 Connect to form a hydraulic damping device. When the workpiece sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com