Medicine bag hot sealing and easily-torn line pressing cutting integral forming device

A technology of forming device and easy tearing line, applied in the directions of transportation and packaging, packaging, transportation and packaging, etc., can solve the problems of the influence of sealing strip alignment, low efficiency, high manufacturing cost, etc., to improve cutting and pressing accuracy and efficiency. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

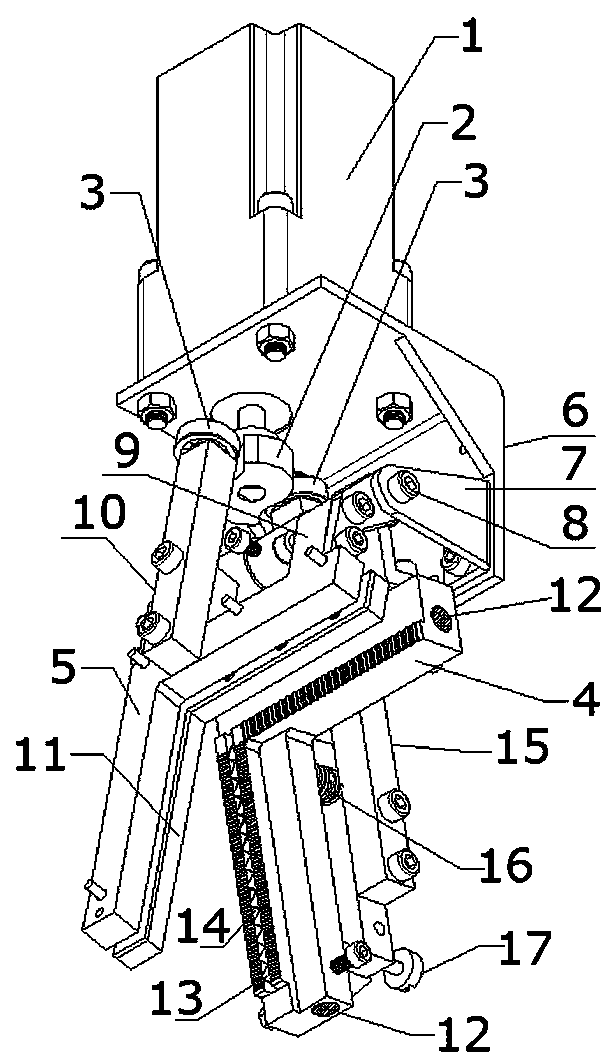

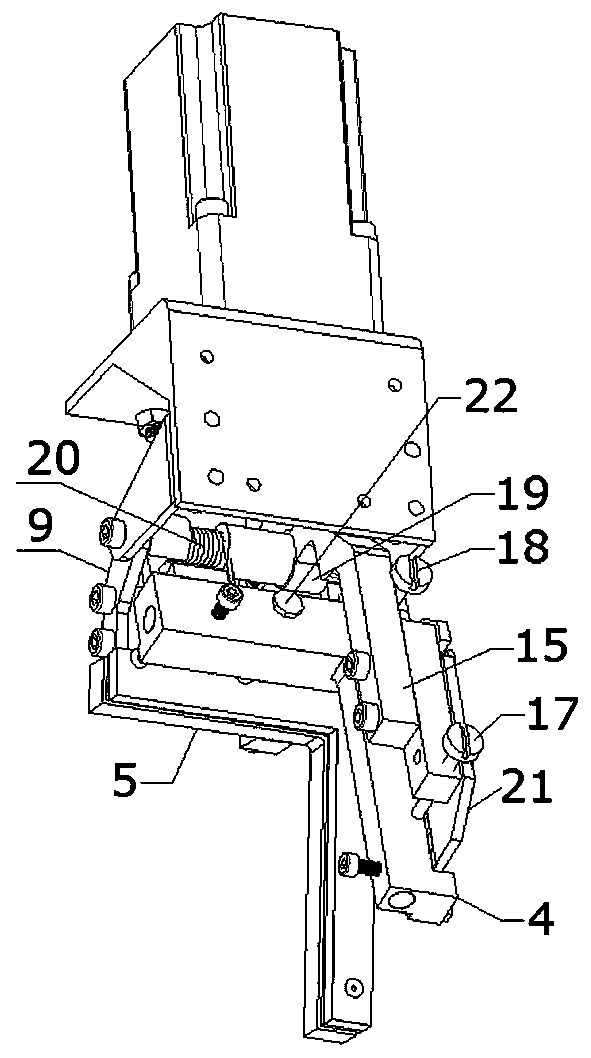

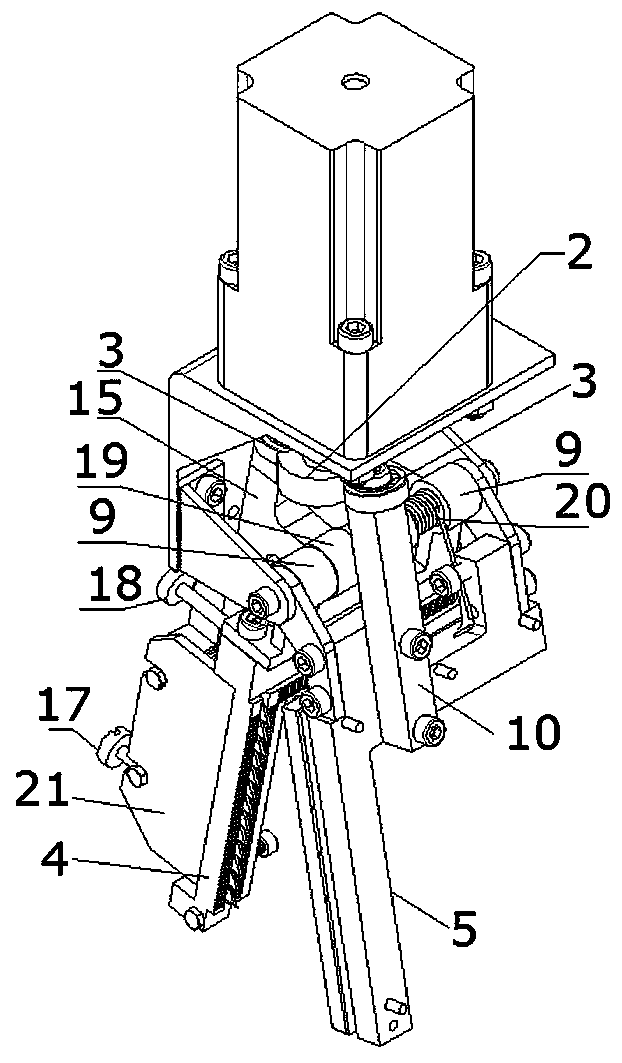

[0023] Such as Figure 1-8 As shown, a medicine bag heat-sealing and easy-tear line pressure-cutting integrated forming device described in this specific embodiment includes a gear motor 1, a bidirectional cam 2, a bearing 3, an L-shaped heat-sealing metal plate 4, and an L-shaped pressure plate 5. Motor seat 6, U-shaped suspension plate 7, suspension pin shaft 8, connecting plate with rotating sleeve 9, first pressure rod 10, L-shaped silica gel plate 11, heating tube 12, blade 13, blade channel 14, second pressure Rod 15, buffer spring 16, adjusting screw rod 17, limit screw rod 18, second pressure rod rotary sleeve 19, torsion spring 20, knife seat 21, temperature sensor 22; geared motor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com