CNC Double Cutter Straight Bevel Gear Milling Machine

A technology of straight bevel gears and gear milling machines, which is applied in gear tooth manufacturing devices, gear cutting machines, belts/chains/gears, etc., can solve the problems of increasing processing costs and machine tool adjustments, configuration time, complex calculations, transmission accuracy and transmission Low efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0029] It should be noted that, unless otherwise specified and limited, terms such as "first" and "second" do not represent sequential installation, nor do they represent the importance of the described components.

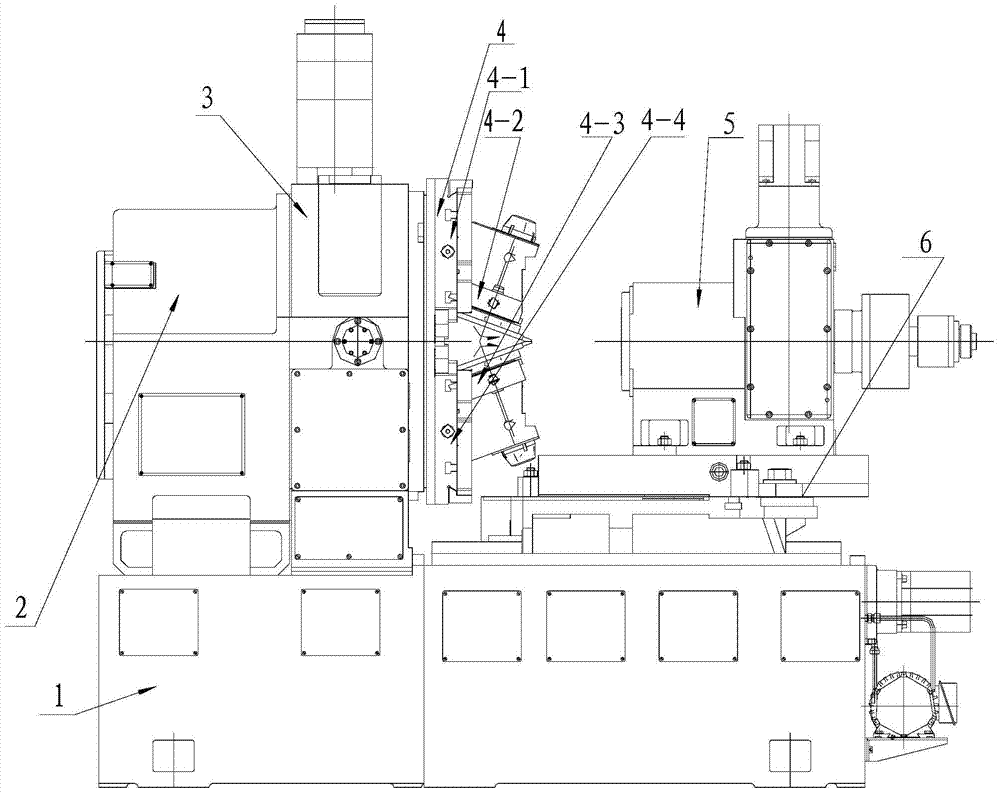

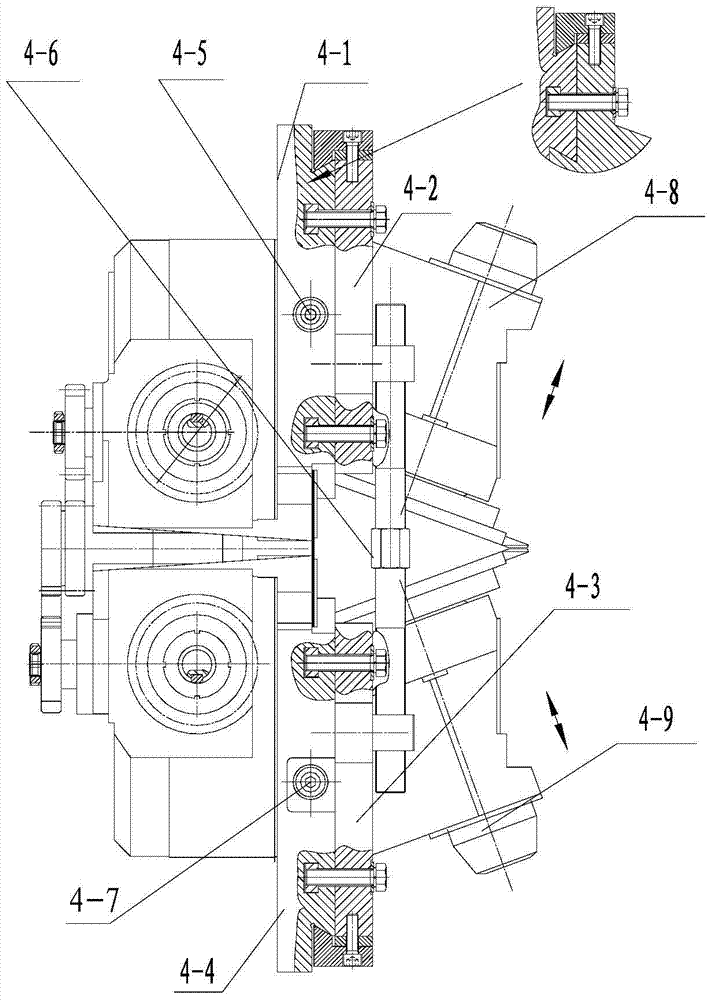

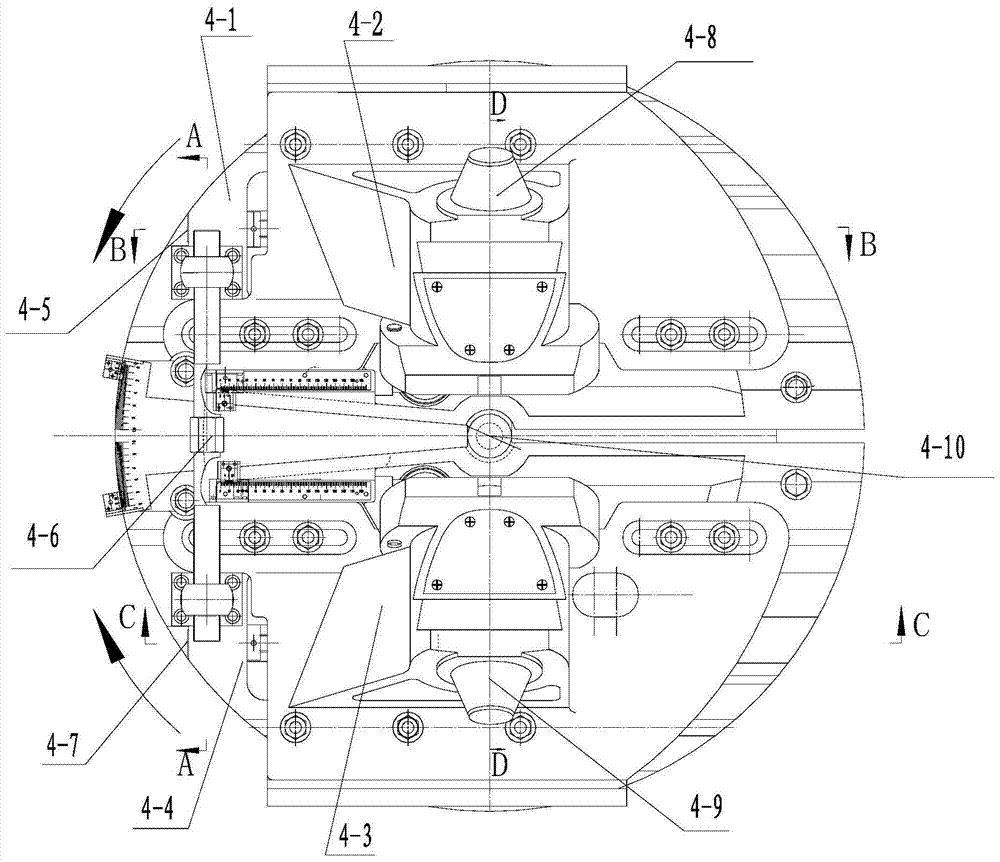

[0030] see Figure 1-Figure 9, CNC double-cutter straight bevel gear milling machine, including bed assembly 1, main drive box assembly 2, cradle assembly 3, tool box assembly 4, workpiece box assembly 5, bed saddle rotary plate assembly 6. Numerical control system, hydraulic system, lubrication system and cooling chip removal system, the numerical control system, hydraulic system, lubrication system and cooling chip removal system are not shown in the figure. The bed assembly is connected with a cradle assembly through fastener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com