Clamping platform for hardware pipe machining

A technology for clamping table and pipe, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of deviation or displacement of hardware pipes, reduced processing quality, insufficient clamping force, etc., and achieves easy separation, low cost, and improved The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

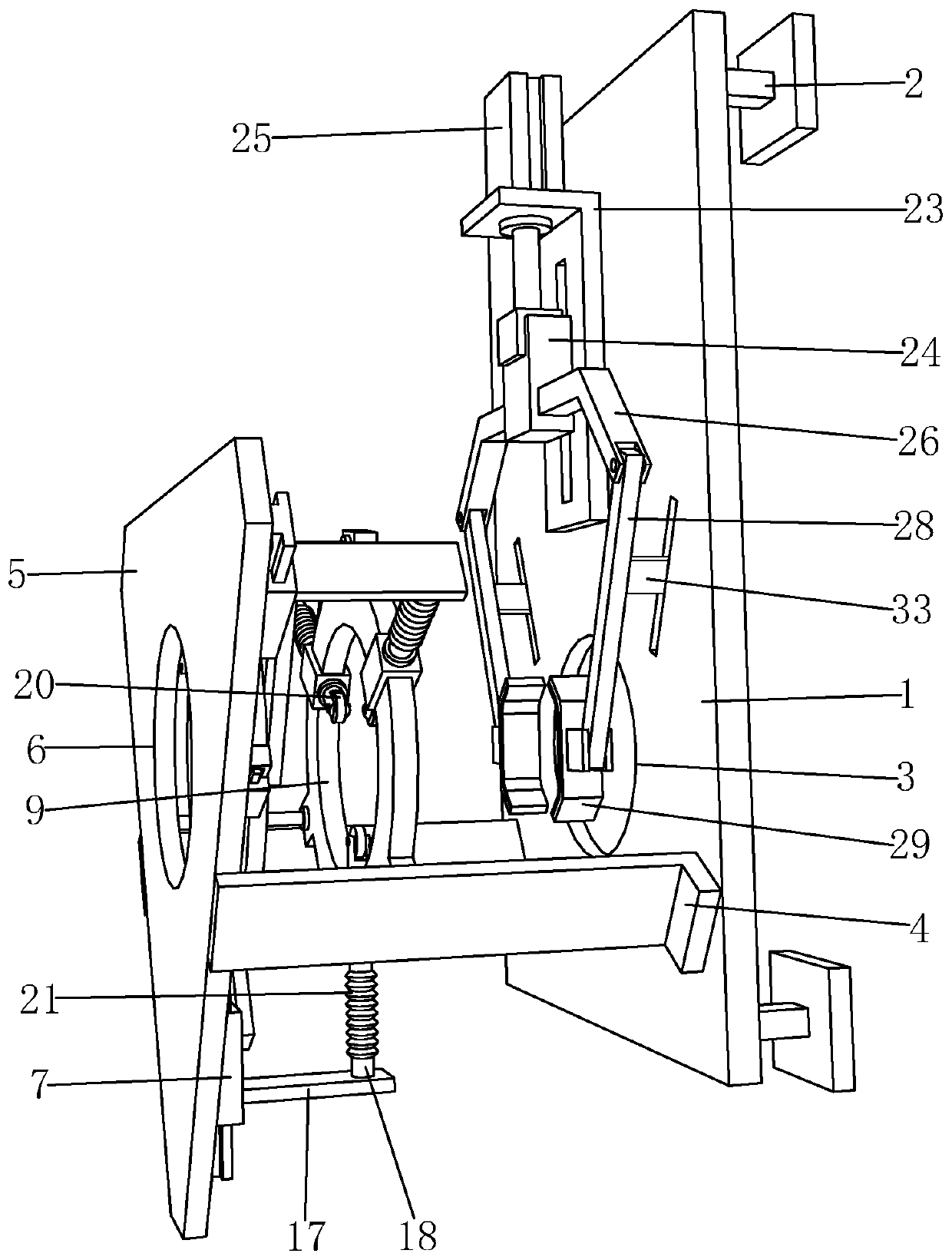

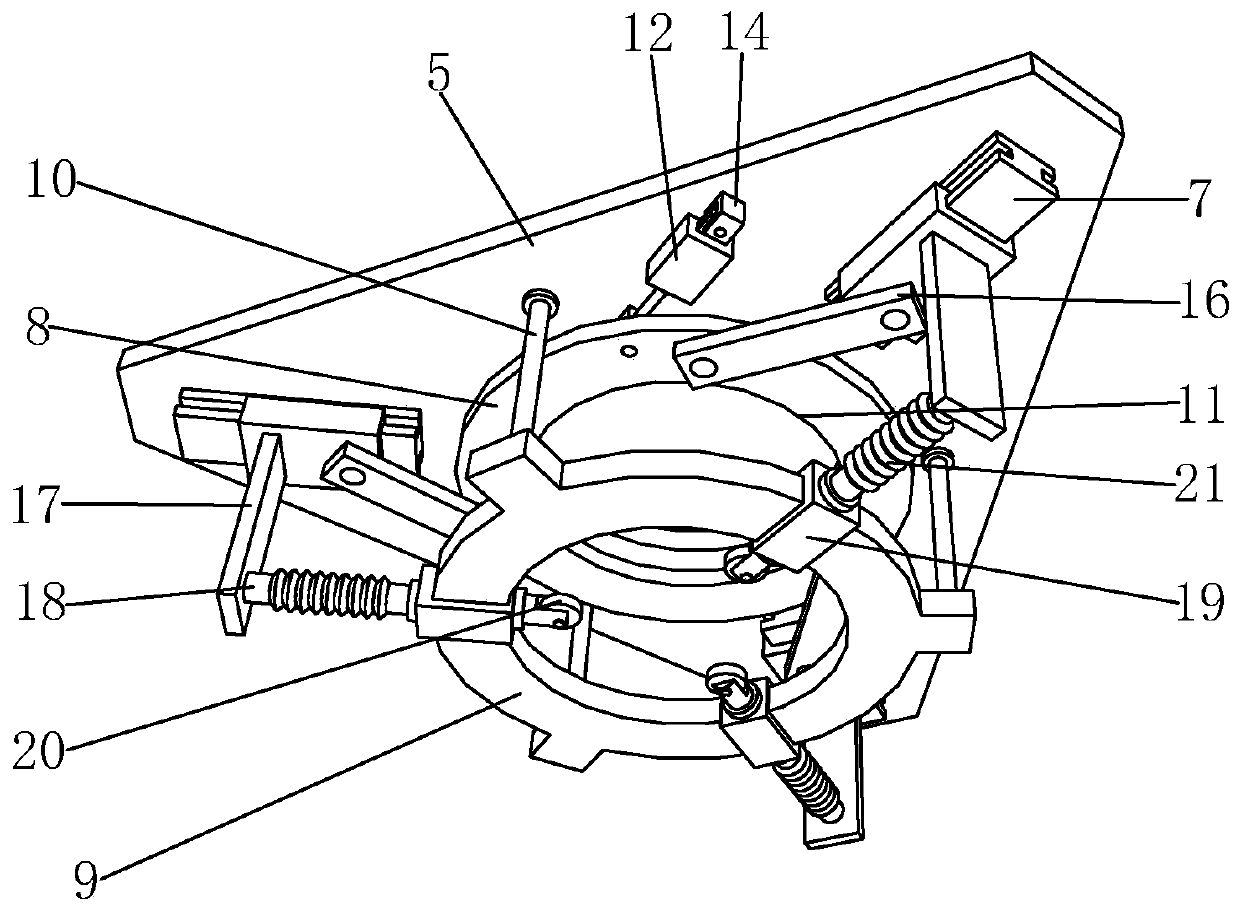

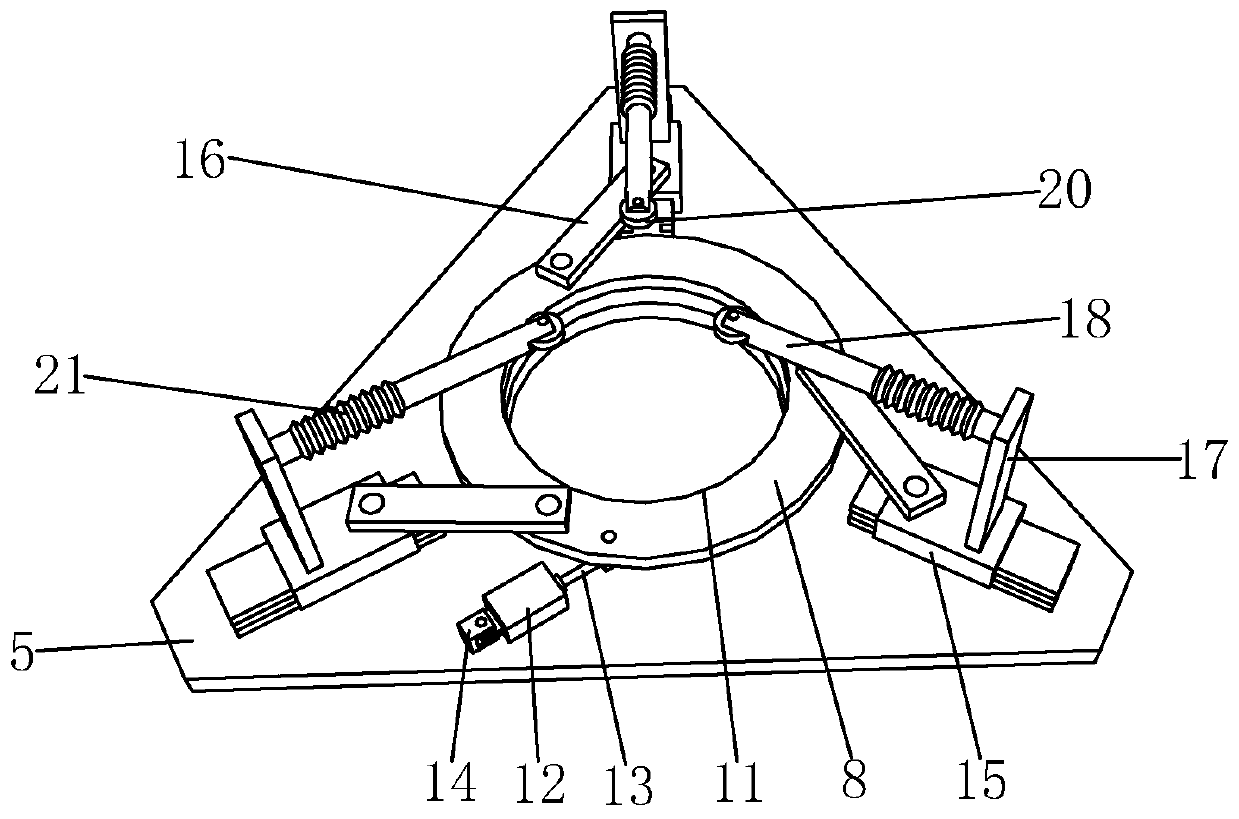

[0025] Such as Figure 1 to Figure 6 As shown, it is a clamping table for metal pipe processing according to the present invention, which includes a workbench 1, four corners of the bottom surface of the workbench 1 are provided with feet 2, and the workbench 1 is respectively provided with accommodating grooves 3 and support The frame 4 and the accommodating groove 3 play a bottom-limiting effect on the metal pipe material, so that the metal pipe material is not easy to slide in a large area after it is initially placed. A triangular plate 5 is arranged between the support frame 4, and the center of the triangular plate 5 is provided with a fixed through hole 6. The bottom surface of the triangular plate 5 is respectively provided with a fixed guide rail 7 and a driving mechanism. The fixed guide rail 7 is distributed around the center of the fixed through hole 6, and the triangular plate 5 is provided with a positioning plate 8 below the positioning plate 8, and a clamp ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com