Engineering method of prefabricated and spliced well-sinking type parking garage and parking garage

A parking garage and caisson technology, applied in the field of parking garages, can solve the problems of inability to realize large excavation parking garage construction in areas with large parking demand, difficult to meet the requirements of safe and civilized construction, occupying a large construction area, etc. The effect of reducing supporting procedures, small footprint, and reducing site settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

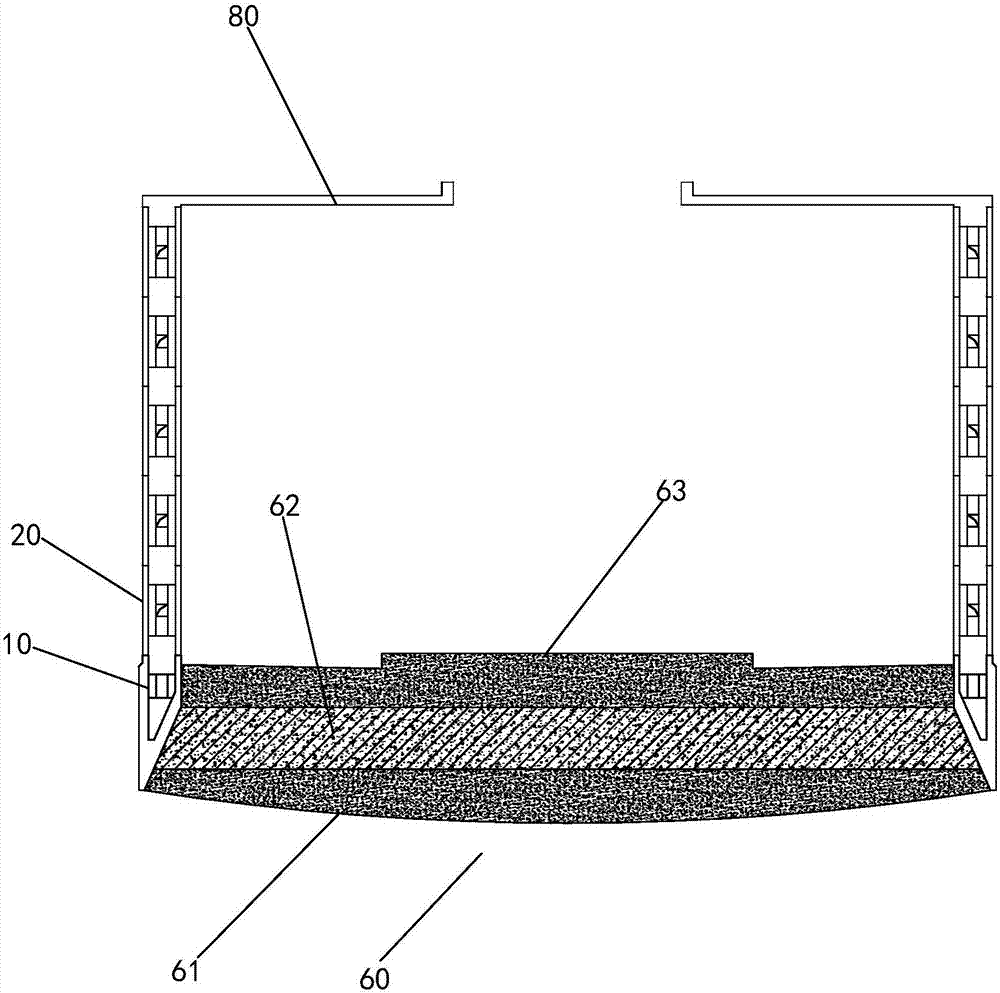

[0080] refer to Figure 16 , an engineering method and parking garage of a prefabricated splicing caisson type parking garage, the main features of which are the same as those of Embodiment 1, the difference being that the bottom cover 60 is only one layer, which is set as a reinforced concrete layer of the foundation floor structure.

Embodiment 3

[0082] refer to Figure 17, an engineering method and parking garage of a prefabricated spliced caisson type parking garage, its main structure is the same as that of Embodiment 1, the difference is that the structure of the blade foot block 10 is different, and it includes a steel formwork frame 19 and connecting steel plates. The steel formwork frame includes an outer steel plate 19a, an inner steel plate 19b and a bottom steel plate 19c. These steel plates are prefabricated in a prefabrication plant and transported to the site for splicing. Connected to form a steel template frame 19 with a hollow cavity. The connecting steel plate is welded on the steel formwork frame 19 for splicing with the standard block. The corresponding outer steel plates 19a, inner steel plates 19b, and bottom steel plates 19c of several blade blocks 10 are sequentially spliced into a cage to form a blade foot layer 10' with a connected inner cavity. The inner cavity of the blade foot layer 10'...

Embodiment 4

[0084] refer to Figure 18 , an engineering method and parking garage of a prefabricated splicing caisson type parking garage, the main structure of which is the same as that of Embodiment 1, the difference being that the structure of the standard block 20 is different. The standard block 20 of this embodiment includes a standard exterior wall panel 21, a standard interior wall panel 22 and a connecting piece 24. Bolt 25. After the standard blocks 20 are transported to the site, the standard exterior wall panels 21 and the standard interior wall panels 22 are fixedly connected with the connectors 24 through bolts 25, and several standard blocks 20 are fixedly connected and spliced into a standard layer 20'. Then the standard layer 20 ′ inner cavity is integrally poured with a reinforced concrete filling layer, and the connector 24 is pre-embedded in the reinforced concrete filling layer of the standard layer 20 ′ inner cavity, and it can adopt I-shaped connectors such as ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com