Dry-mixed mortar production system

A production system and technology for dry-mixed mortar, which are applied in the direction of selling raw material supply devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of high work intensity and low work efficiency, and reduce work intensity, save materials and finished products. Excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

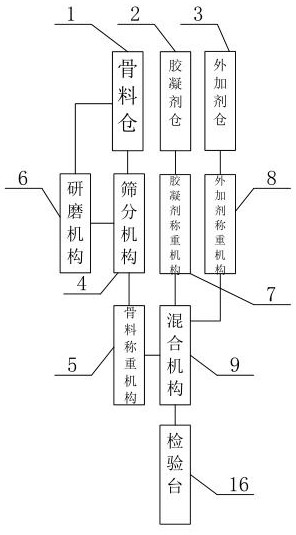

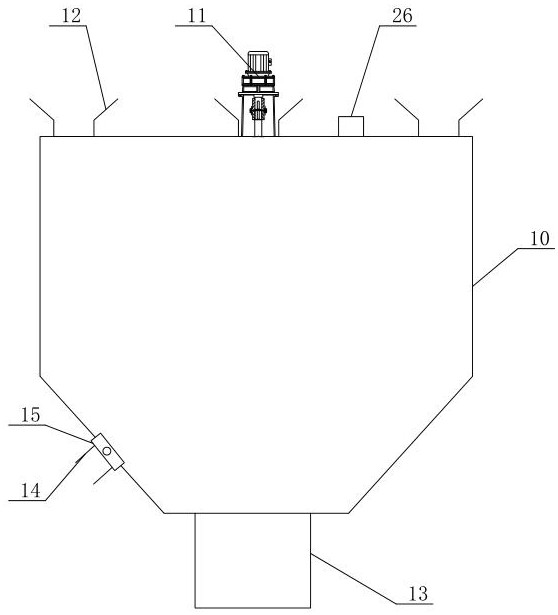

[0025] see figure 1 —3, a dry-mixed mortar production system, including an aggregate bin 1, a gelling agent bin 2, and an admixture bin 3, and the aggregate bin 1, the gelling agent bin 2, and the admixture bin 3 are respectively used for storing aggregates Yellow sand, gelling agent cement, admixture polymer, aggregate silo 1, gelling agent silo 2, and admixture silo 3 are equipped with electric discharge gates at the bottom outlets, and the outlets of aggregate silo 1 are connected There is a screening mechanism 4, which can make the aggregate freely fall to the screening mechanism 4 through the action of gravity, and the aggregate in the aggregate bin 1 is screened through the screening mechanism 4, and the screened aggregate is divided into the following categories: For the fine aggregate required and the coarse aggregate that does not meet the requirements, the fine discharge port of the screening mechanism 4 is connected with the aggregate weighing mechanism 5 through th...

Embodiment 2

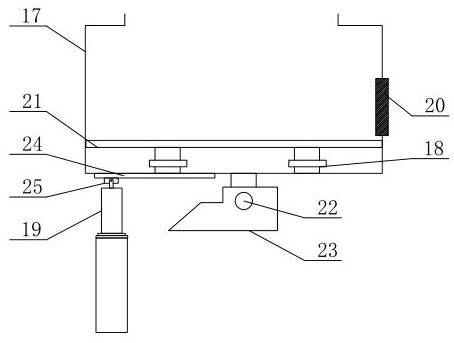

[0029] see figure 1 —3. A dry-mixed mortar production system. The aggregate weighing mechanism 5 in Embodiment 1 includes a weighing box 17, a load cell 18, and a hydraulic telescopic cylinder 19. One side of the weighing box 17 is provided with a discharge port. An electric feeding gate 20 is arranged on the mouth, a load cell 18 is fixedly installed on the inner bottom of the weighing box 17, and a weighing platform 21 is fixedly connected to the upper part of the load cell 18, and a group of rotating shafts 22 are fixedly connected to the outer bottom of the weighing box 17, and two rotating shafts 22 are fixedly connected. The end is rotatably connected on the turntable 23, and a group of chute 24 is arranged on the outer bottom of the weighing box 17, and the inside of the chute 24 is slidably connected with a slider 25, and the slider 25 is rotatably connected with a hydraulic telescopic cylinder 19, and the hydraulic telescopic cylinder 19 can be Installed on the bracke...

Embodiment 3

[0034] see figure 1 —3, a dry-mixed mortar production system, which is basically the same as Embodiment 1, furthermore, it also includes a control mechanism, the control mechanism includes a central control module, a wireless signal transmission module, and a PC terminal, and the central control module is used to carry out Analysis and processing of data and output of control signals;

[0035] The wireless signal transmission module is used for wireless transmission of data signals;

[0036] The PC terminal is used to monitor and control signal release;

[0037] The electric discharge gate, weighing sensor 18, electric conveying gate 20, and hydraulic telescopic cylinder 19 are all connected to the signal of the central control module. The weight required to be weighed by the load sensor 18, when the weight is reached, the central control module controls the electric feeding gate 20 to open, and at the same time closes the electric discharge gate, and the hydraulic telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com