Prefabricated stair and production and construction method thereof

A construction method and stair technology, applied in the direction of stairs, manufacturing tools, pedals and riser units, etc., can solve the problems of poor paving effect, insufficient connection strength, slow manual paving, etc., and achieve the reduction of cast-in-place formwork and support system, shorten the construction period, and pre-embed the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

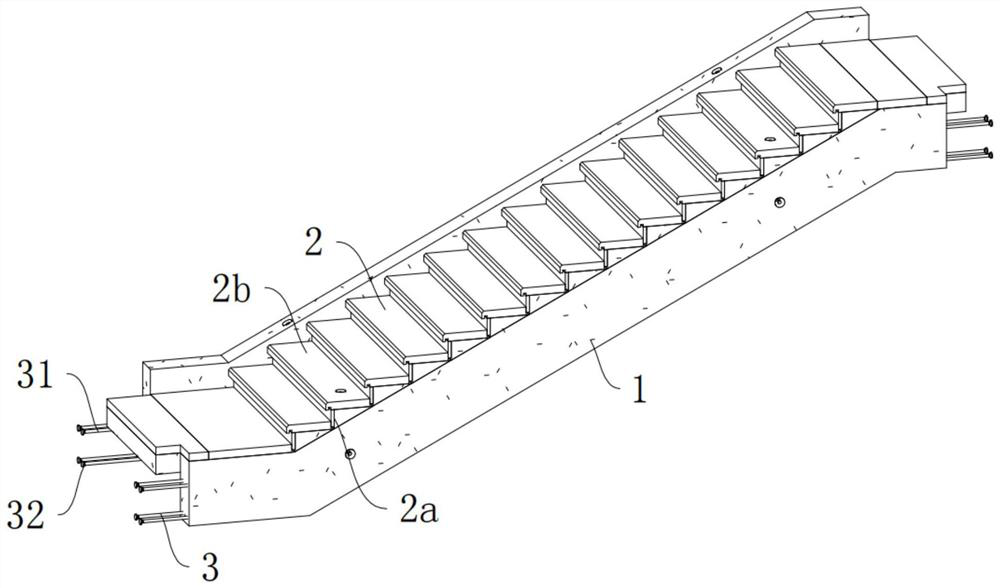

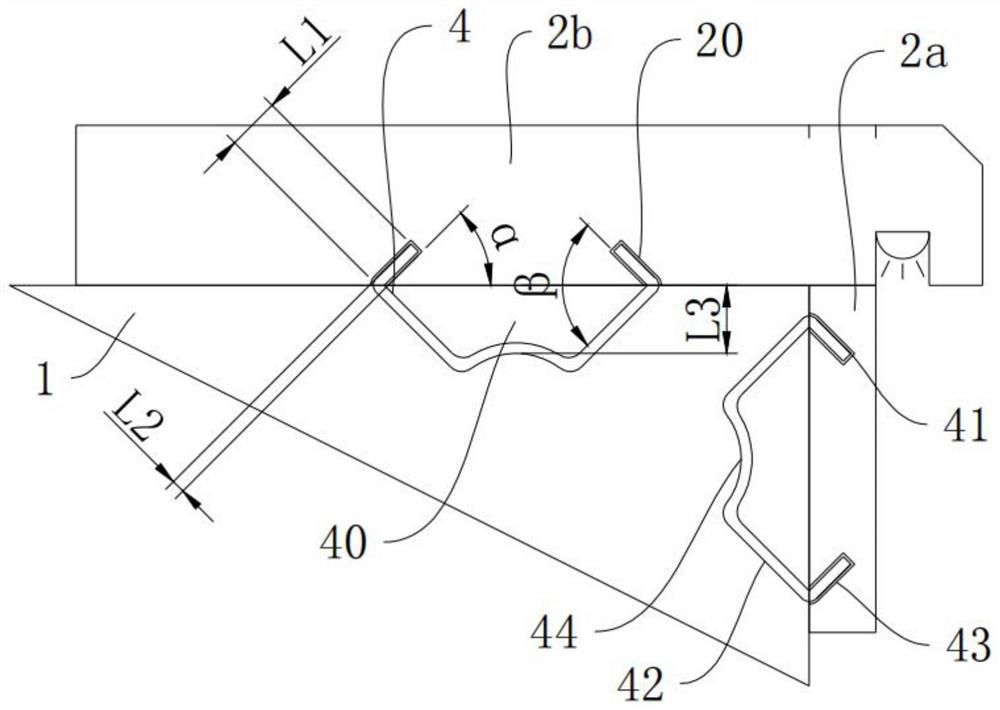

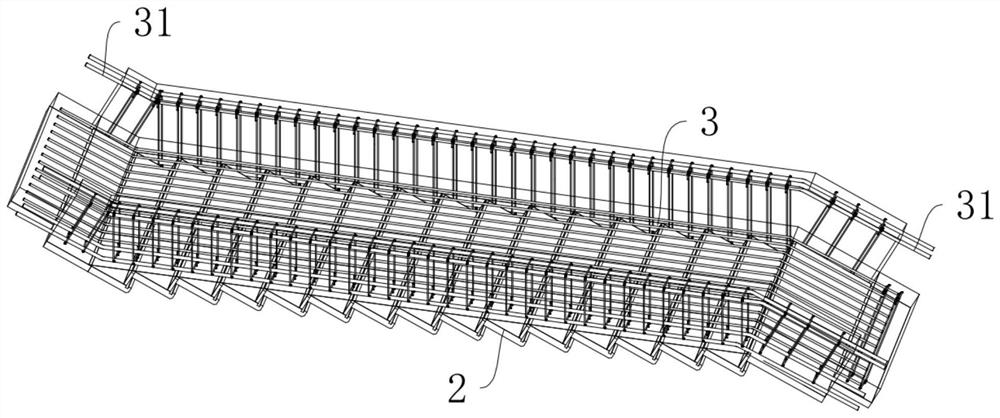

[0051] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 as shown, figure 1 It is a perspective view of the prefabricated staircase of the present invention, figure 2 It is the schematic diagram that the stone material of the prefabricated staircase of the present invention is connected with claw nails, image 3 It is the schematic diagram of the reinforcement cage of the prefabricated staircase of the present invention, Figure 4 It is the schematic diagram of prefabricated staircase lifting of the present invention, Figure 5 It is a schematic diagram of the installation of prefabricated staircase components of the present invention.

[0052] A production and construction method for prefabricated stairs, including bottom form assembly, stone install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com