Method for granulation of bakelite powder under hot melt state and equipment thereof

A technology of bakelite powder and granulation equipment, which is applied in the field of bakelite powder hot granulation and its equipment, can solve the problems of high cost, high energy consumption, low production efficiency of cold granulation method, etc., and achieves good quality of finished products and environmental pollution. The effect of less production equipment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

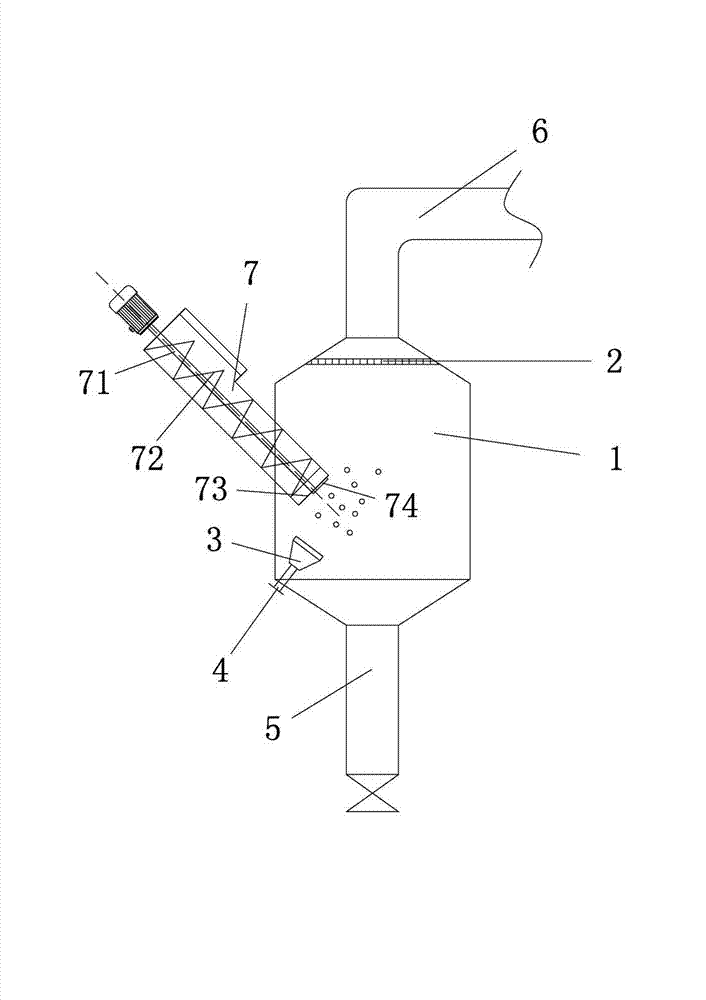

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

[0017] This specific embodiment is an explanation of the present invention, not a limitation of the present invention. Any improvements and modifications made by those skilled in the art after reading the description of the present invention will be protected by law as long as they are within the scope of the claims of this application document.

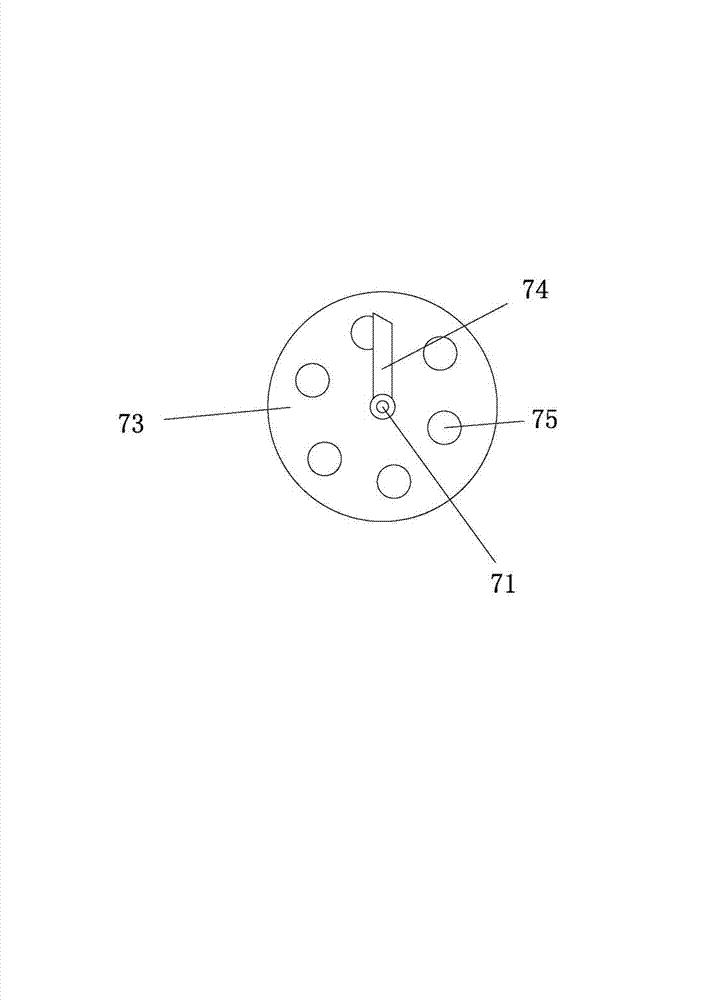

[0018] A thermal granulation method of bakelite powder, comprising heating the bakelite powder to form a molten clot, characterized in that the bakelite powder in the form of a molten clot is added to a screw extruder to extrude into thin strips and cut into granules, and cooled After the granular product is obtained; at the extrusion port of the screw extruder, the thin strips of the bakelite powder clot are cut into granules by the rotary cutting blade; The compressed air is blown to the particles to suspend, disperse and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com