Patents

Literature

42 results about "Bound copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inhibition Of Superoxide Dismutase By Tetrathiomolybdate: Identification Of New Anti-Angiogenic And Antitumor Agents

InactiveUS20080031817A1Prevent proliferationInhibit angiogenesisBiocideCompound screeningAnticarcinogenDepressant

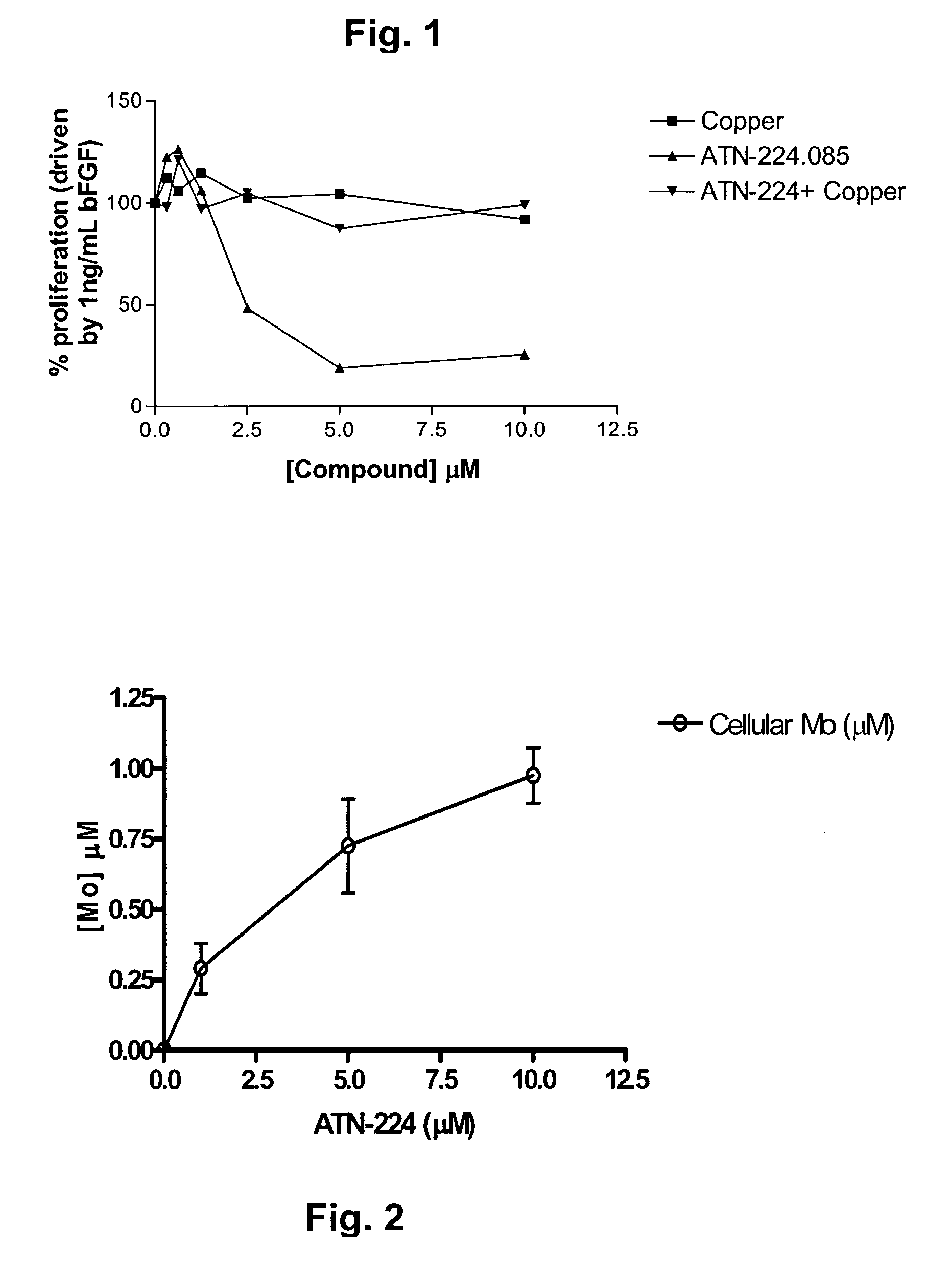

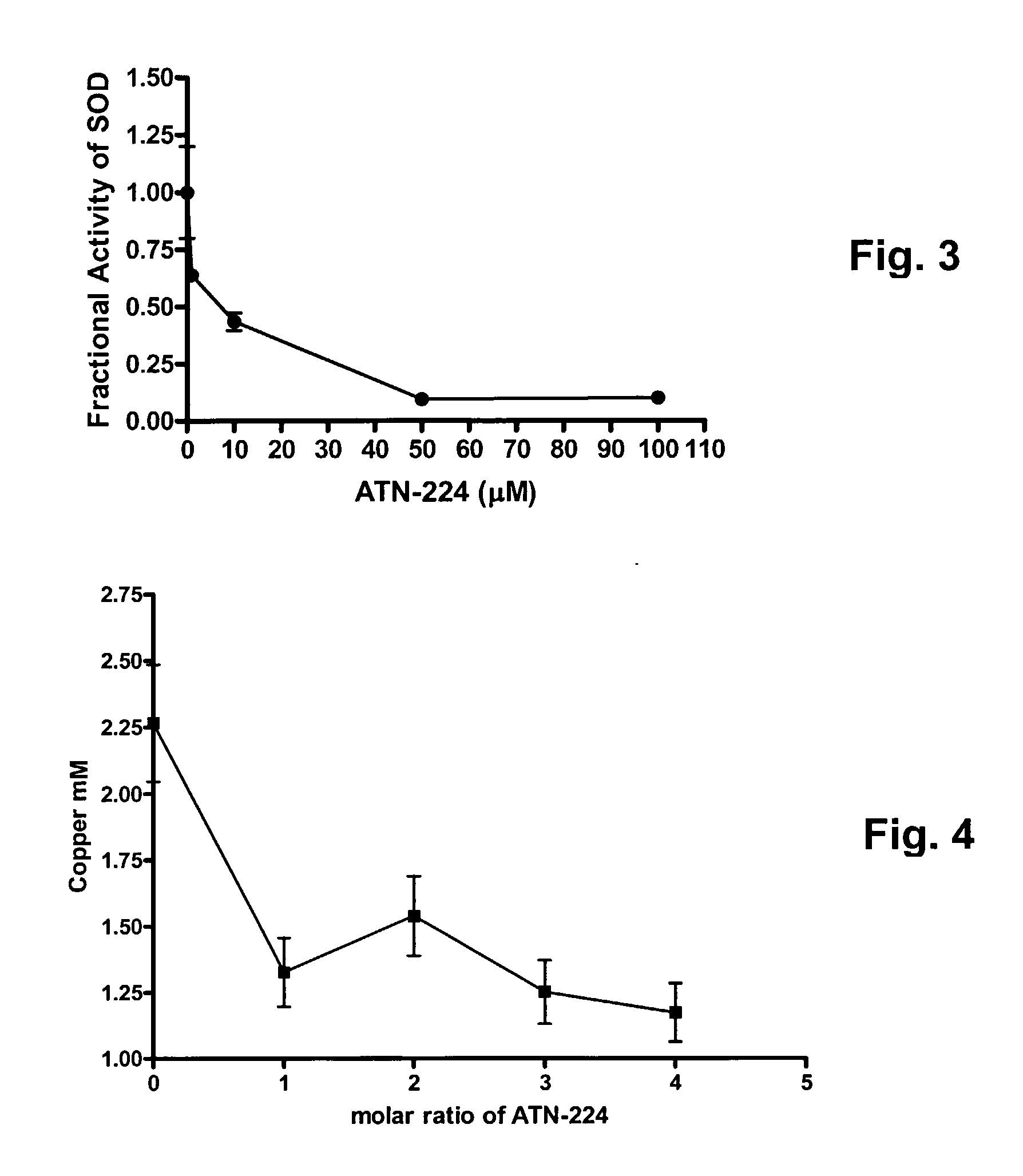

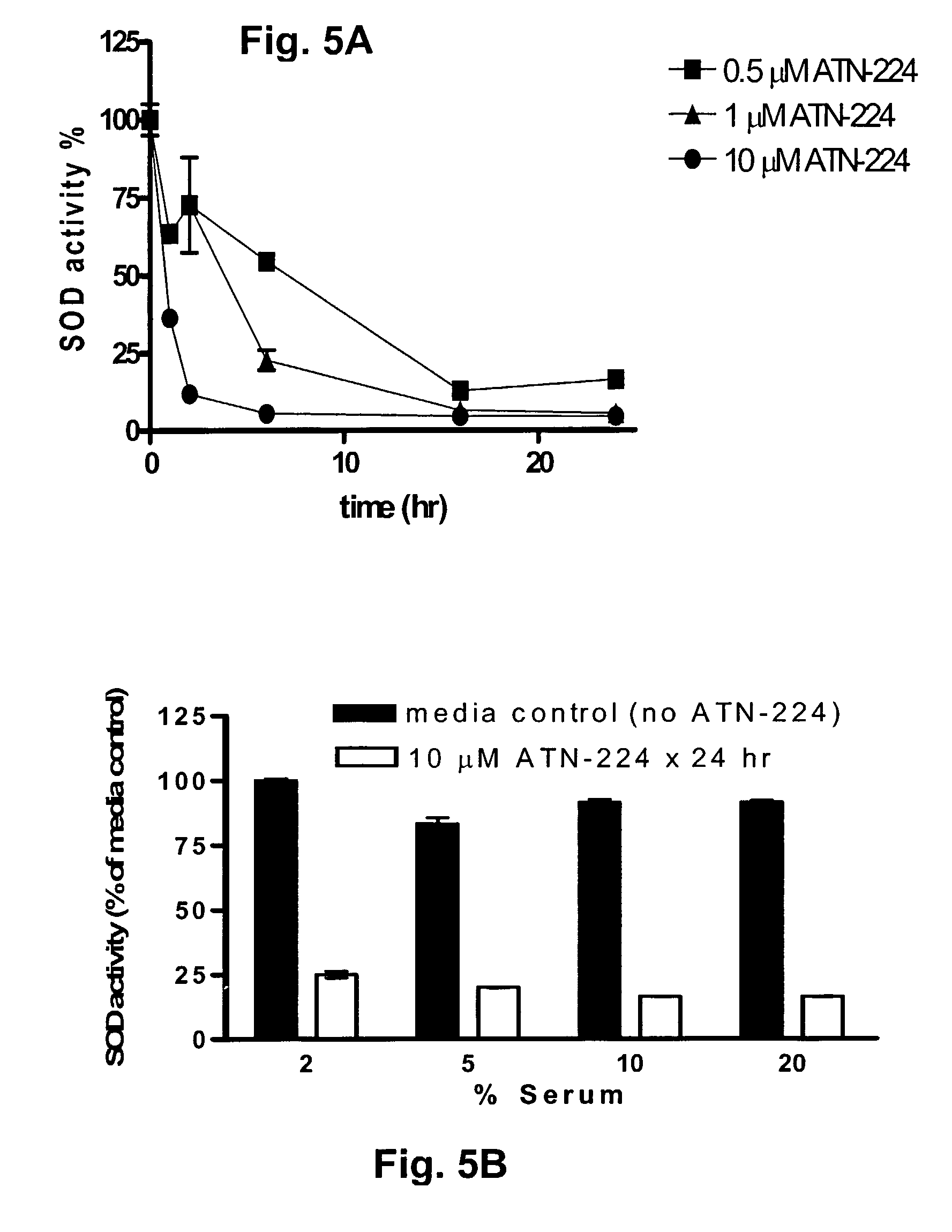

Though copper is elevated in the tumor tissue and plasma of patients with various malignancies, the molecular targets for copper binding agents in angiogenesis and tumor progression remain poorly understood. It is disclosed that one anti-angiogenic target for the copper binding agent tetrathiomolybdate is intracellular CuZn-superoxide dismutase (SOD1). A second generation tetrathiomolybdate analog, ATN-224, inhibits endothelial cell (EC) proliferation in vitro, binds to SOD1 and inhibits its activity without displacing bound copper ATN-224 can accumulate in ECs and inhibit CuZnSOD activity with an IC50 similar to the IC50 for EC proliferation, resulting in increased generation of intracellular reactive oxygen species. Inhibition of EC proliferation by ATN-224 in vitro is substantially reversed by a synthetic porphyrin SOD mimetic. Similar results were observed in vivo, where inhibition of angiogenesis by ATN-224 in a Matrigel plug model was also reversed by MnTBAP. Thus, a distinct molecular target for copper depletion therapy has been identified and SOD1 is now validated as a target for anti-angiogenesis. Methods for screening, or designing, such SOD1 inhibitors for use as angiogenesis inhibitors and anti-cancer agents are disclosed.

Owner:ATTENUON LLC

System for treatment of acid mine drainage and resource recovery of iron, aluminum, copper and zinc in drainage

ActiveCN102311189AEliminate pollutionEliminate hidden dangers of secondary pollutionWater contaminantsMultistage water/sewage treatmentSolubilityAcid mine drainage

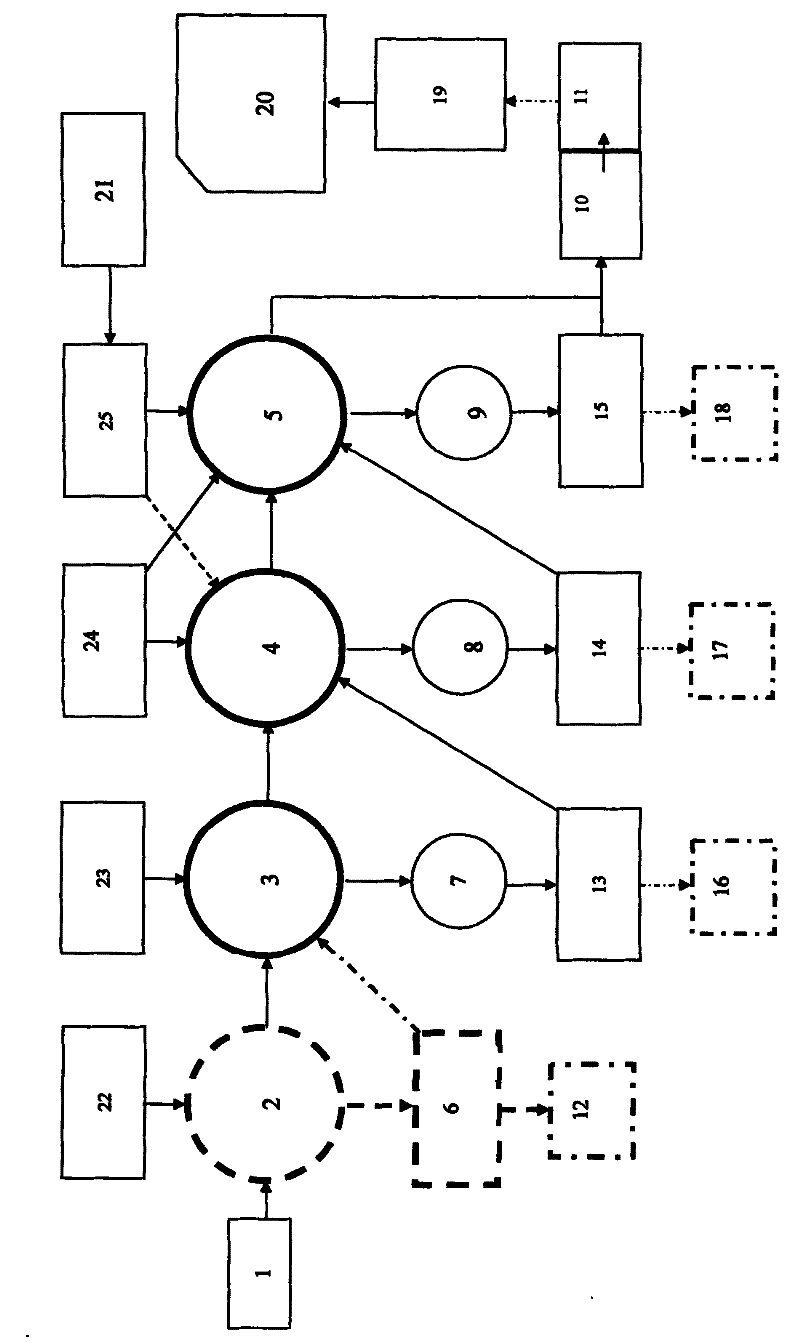

The invention belongs to the field of wastewater treatment and specially, relates to a system for treatment of acid mine drainage and resource recovery of iron, aluminum, copper and zinc in drainage. The system is characterized in that the system is composed of an iron removal system, an aluminum removal system, a copper removal system, a zinc removal system, a sedimentation basin 1 and a sedimentation basin 2 by sequential connection. Based on differences of precipitation performances of a metal ion under pH conditions and differences of solubility products (Ksp) of a reaction between copperand a sulfur-containing organic chelating agent and a reaction between zinc and the sulfur-containing organic chelating agent, through a fractional precipitation method, iron, aluminum, copper, zinc and the like are separated effectively; resource recovery and utilization is realized; hidden troubles of secondary pollution caused by waste residues are eliminated; and treated drainage reaches a reuse standard and can is fed directly into mineral processing pool for reuse. The system has the advantages of simple process, good effect of drainage treatment, stable operation, low costs of treatment, capital construction investment, energy consumption and operation, and wide application prospect.

Owner:马前 +1

Methods of controlling proliferation and differentiation of stem and progenitor cells

InactiveUS20020114789A1Faster rateIncreased RA-induced differentiationBiocidePeptide/protein ingredientsProgenitorBound copper

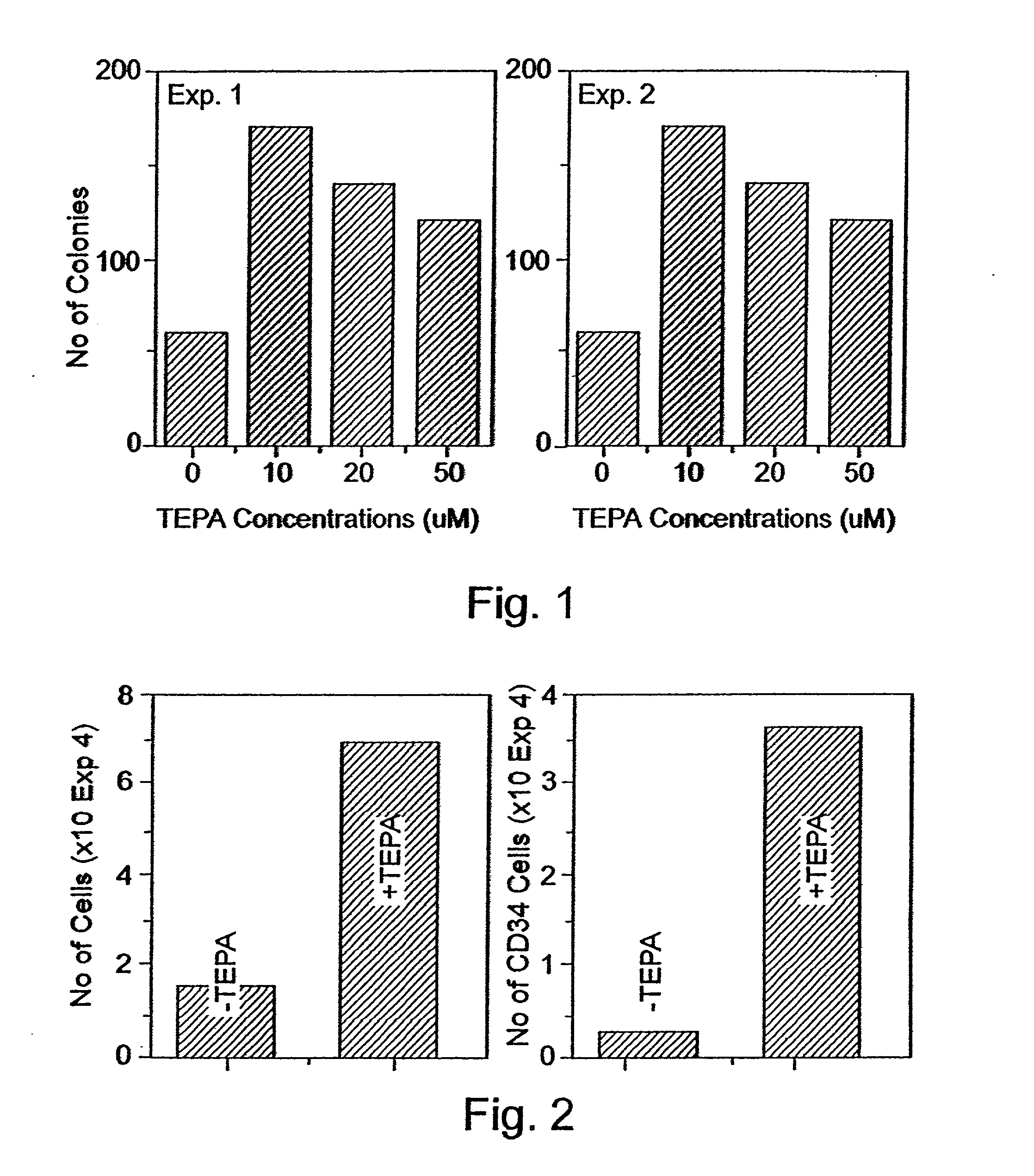

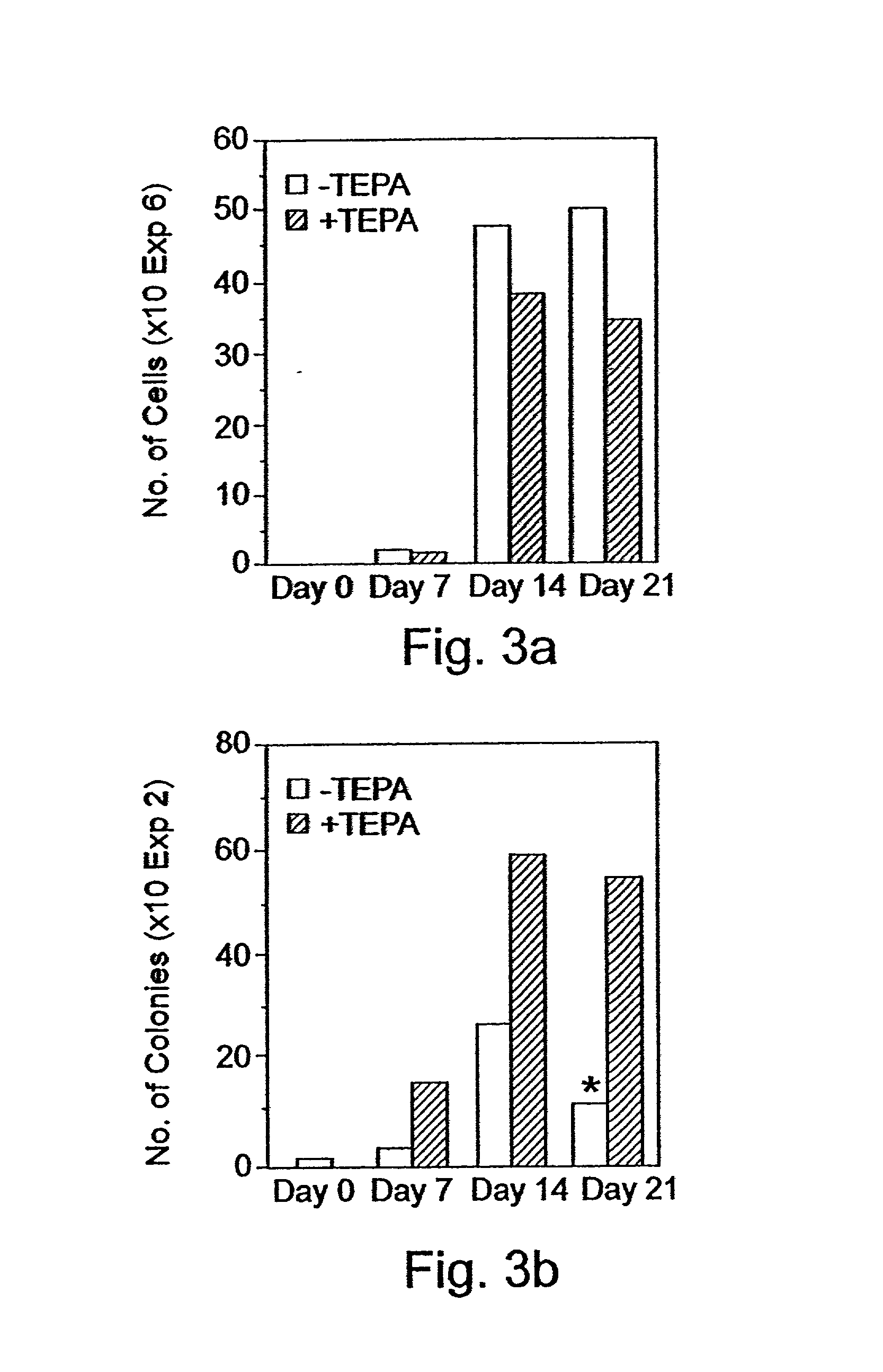

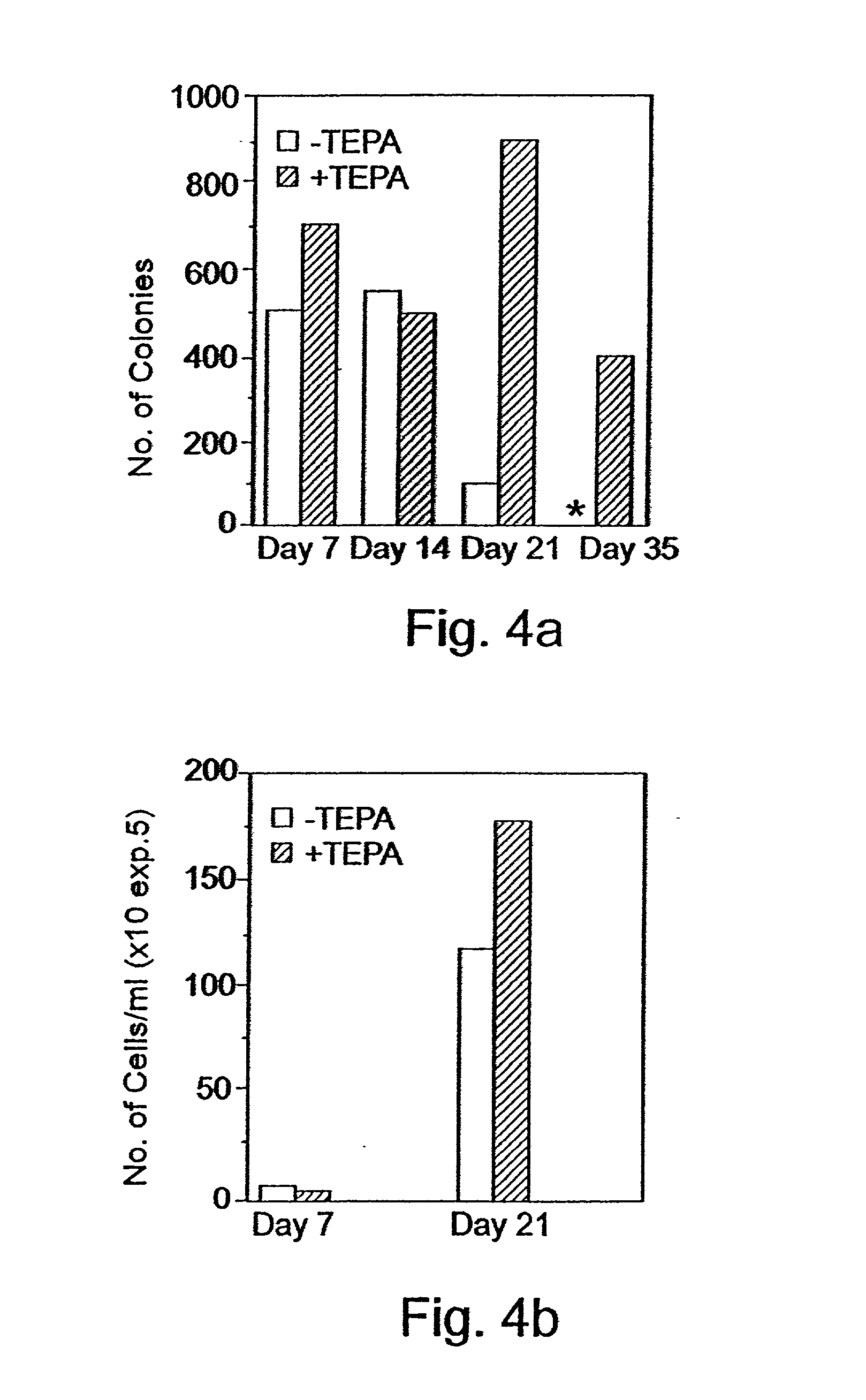

A method of expanding a population of cells, while at the same time inhibiting differentiation of the cells, the method includes the step of providing the cells with conditions for cell proliferation and, at the same time, for reducing a capacity of the cells in utilizing copper. The method can be executed both in-vivo and ex-vivo. A method of inducing differentiation in a population of cells, the method includes the step of providing the cells with a transition metal chelator which binds copper and which is effective in inducing cell differentiation.

Owner:PELED TONY +2

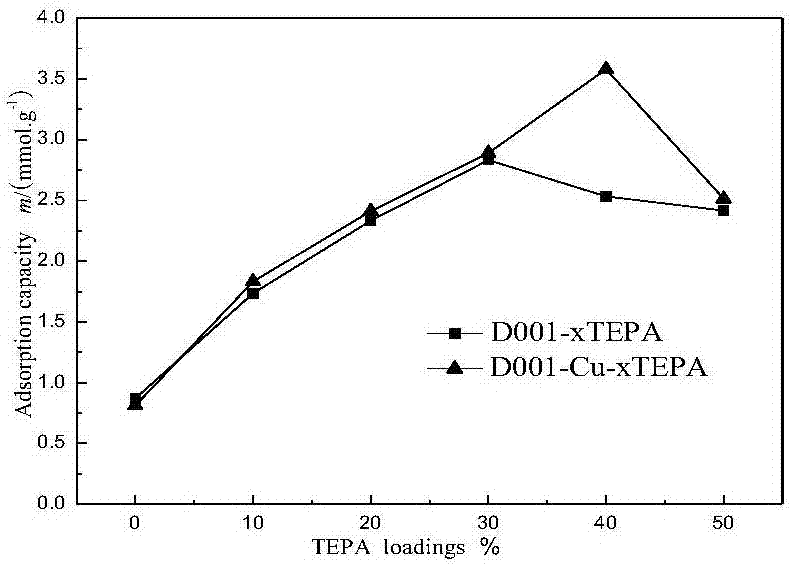

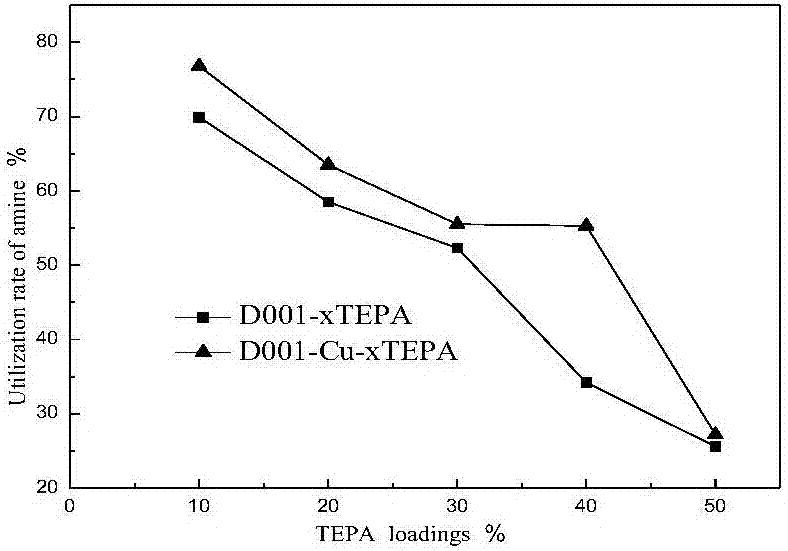

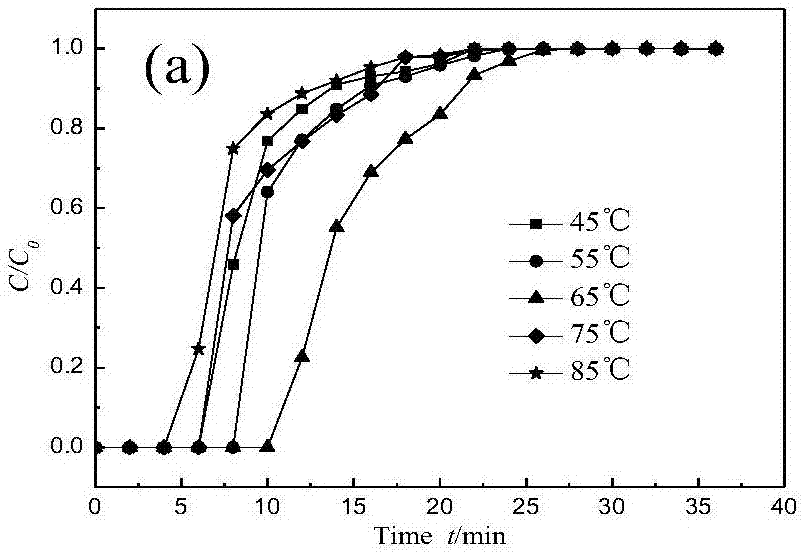

Solid amine carbon dioxide adsorption material, preparation method and application

The invention relates to a solid amine carbon dioxide adsorption material, a preparation method and application. According to the preparation method, liquid organic amine is loaded to ion exchange resin through a collocation method. The preparation method includes the steps that 1, the ion exchange resin is soaked in a copper chloride solution to make copper ions combined to the resin in exchange; 2, TEPA is dissolved in methyl alcohol, the resin combined with the copper ions is soaked in the solution, and ultrasonic treatment is conducted for 3 h; 3, vacuumizing is conducted to remove the methyl alcohol solvent, drying is conducted, and the solid amine adsorbent is obtained. The material is placed in a fixed bed, a CO2 adsorption test is conducted, and adsorption conditions are optimized; when the TEPA loading amount is 40%, the adsorption temperature is 65 DEG C, and the air inflow is 40 mL / min, a maximum CO2 adsorption amount of 4 mmol / g is achieved. Besides, the preparation method is simple, the regeneration energy consumption is low, the organic amine is dispersed uniformly, and the stability of repeated use is high.

Owner:QINGDAO UNIV OF SCI & TECH

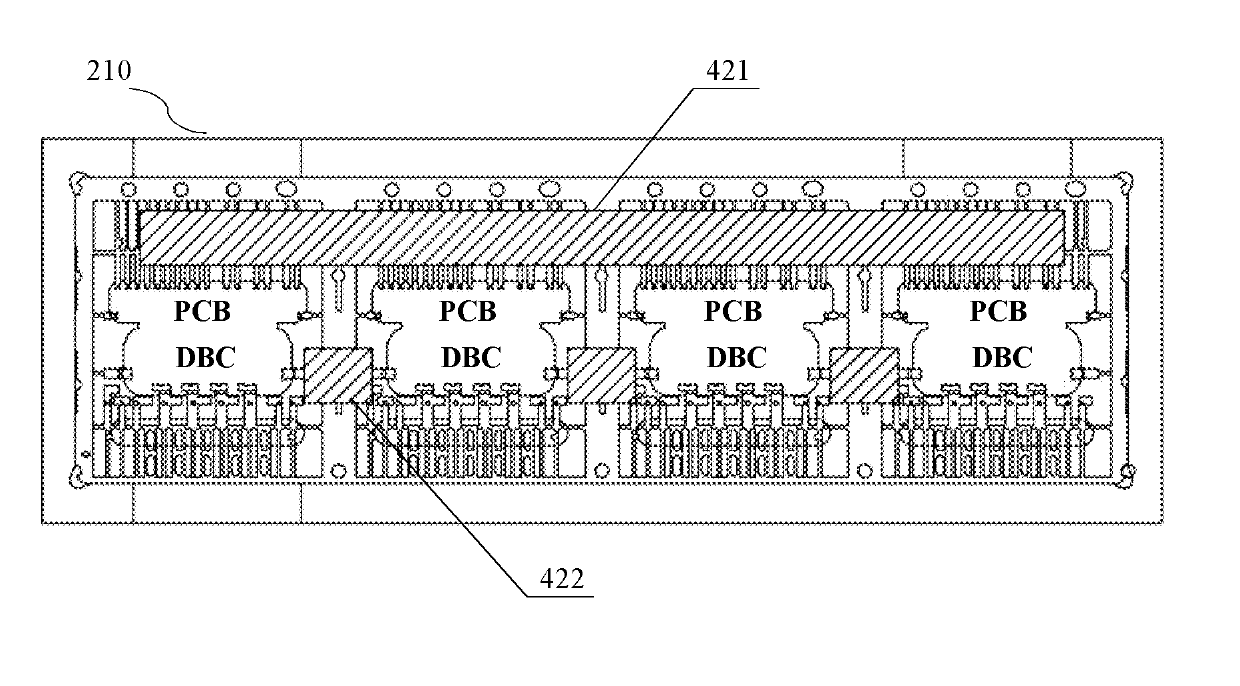

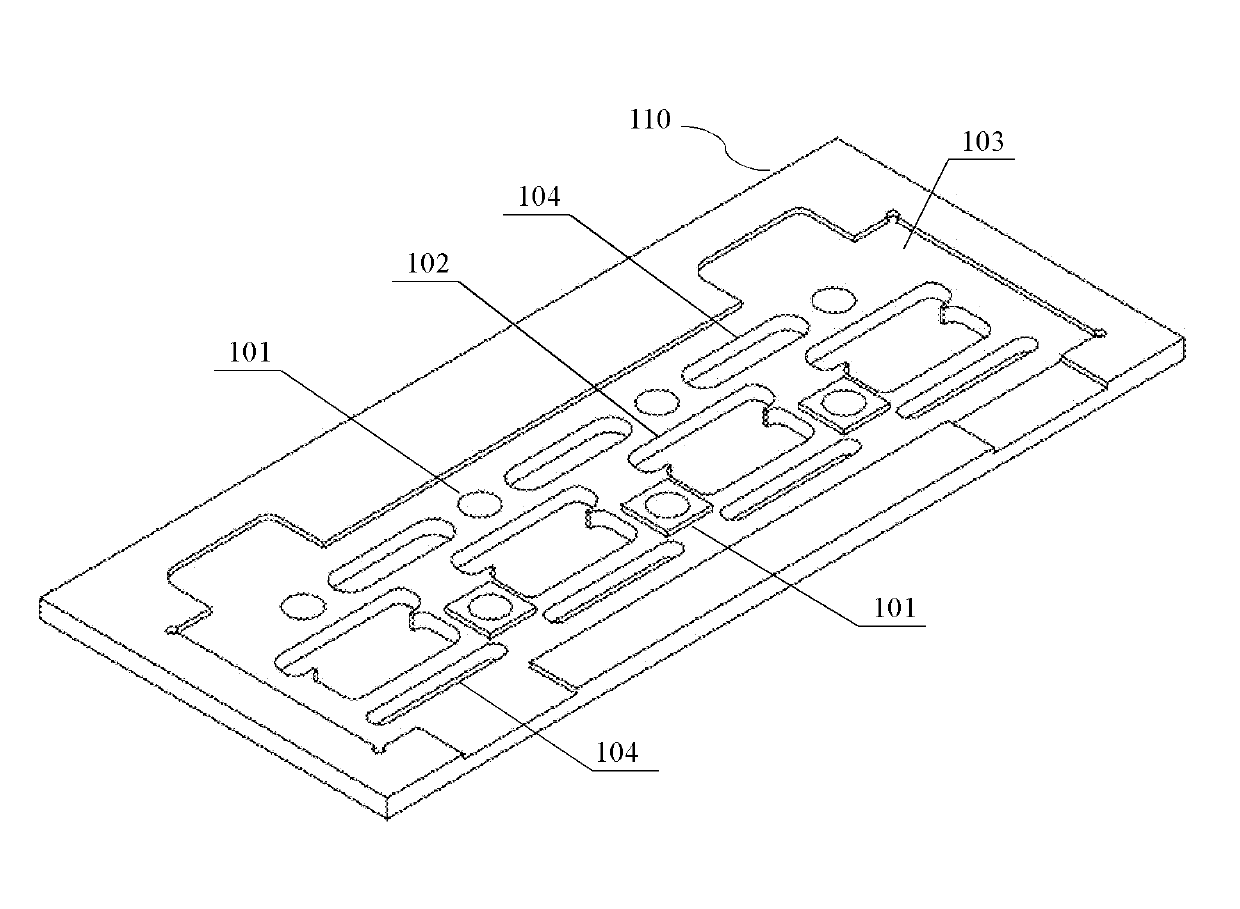

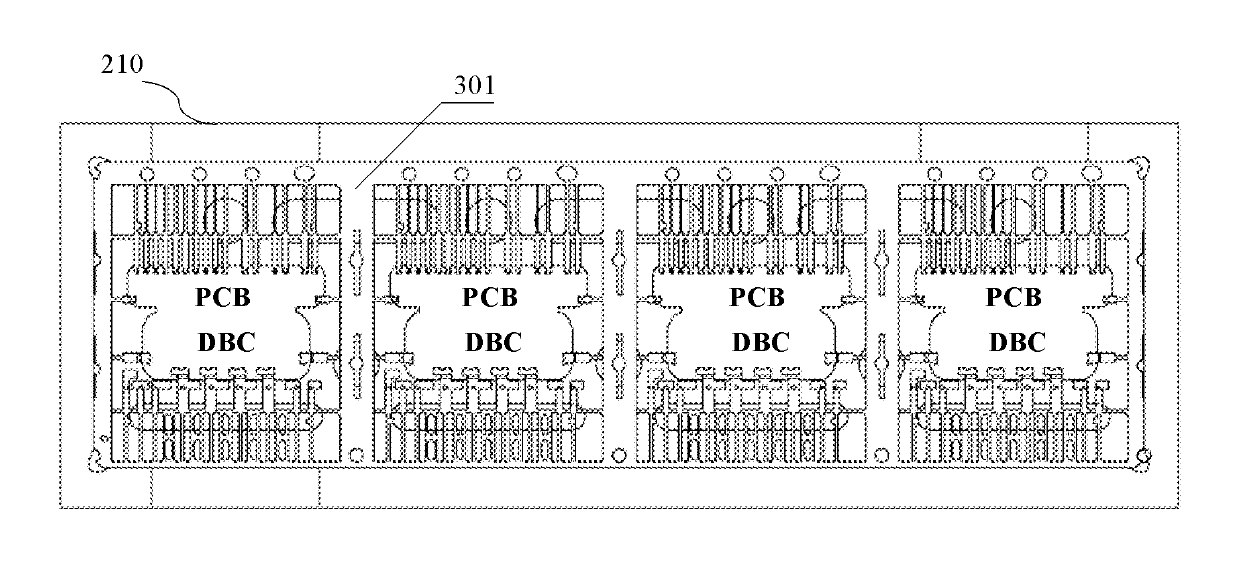

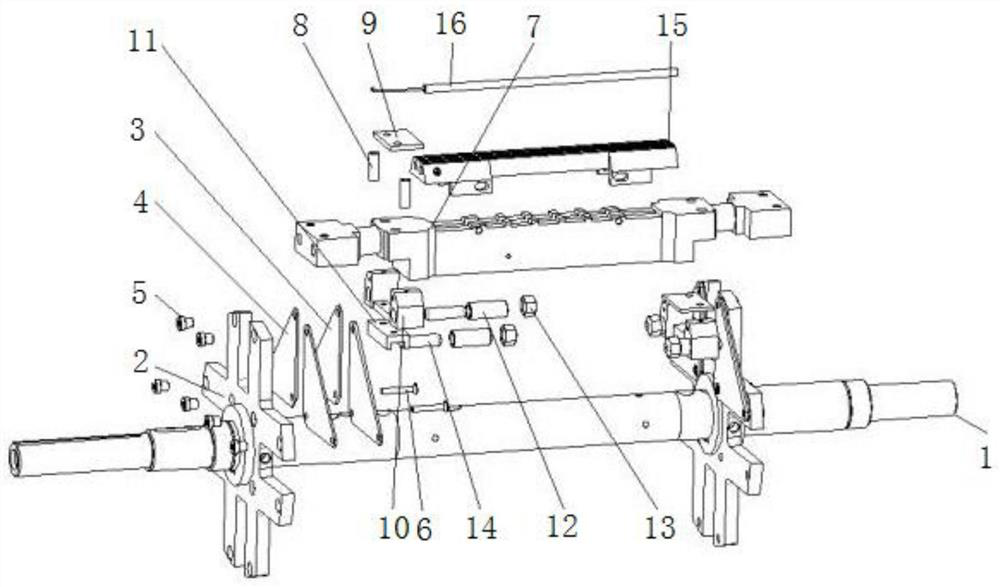

Furnace-through fixture for reflow soldering

The invention relates to a furnace-through fixture for reflow soldering. The furnace-through fixture is used for bearing printed circuit boards (PCB), direct bounding coppers (DBC) and a lead frame array during the reflow soldering process. The furnace-through fixture comprises: a carrier board which is provided with a plurality of clamp holes for positioning and fixing the PCBs and the DBCs and a clamp groove for positioning and fixing the lead frame array, besides, a plurality of magnetic contacts are arranged on the parts of the carrier board that are beyond the clamp holes and that are covered by the lead frame array; and magnetic covers which are for exerting pressure on the lead frame array that is between the magnetic covers and the carrier board to fasten the lead frame array when the magnetic covers are adsorbed on the magnetic contacts.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

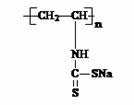

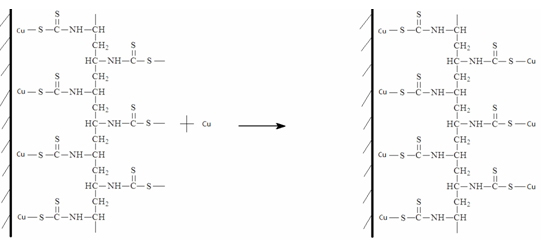

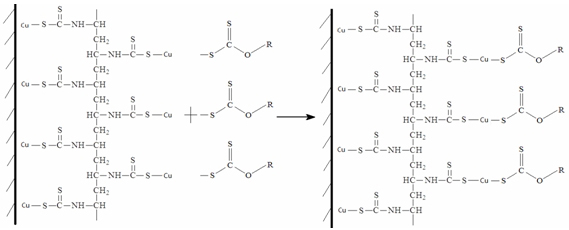

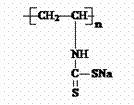

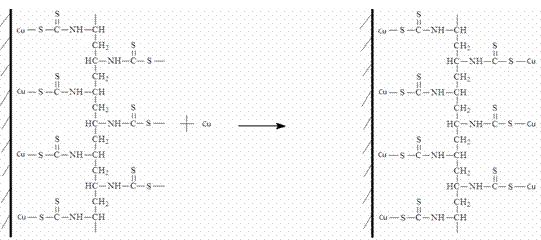

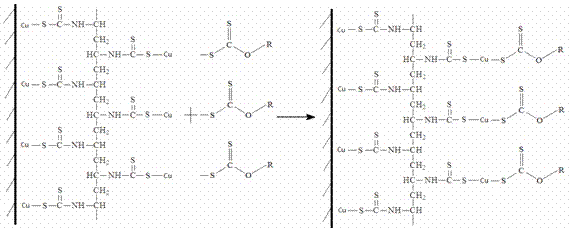

Macromolecule bridging flotation method for combined copper disseminated body

The invention provides a macromolecule bridging flotation method for a combined copper disseminated body, and aims to the combined copper disseminated body which can not be recycled through a conventional flotation manner. The method comprises the following steps of: adopting macromolecule bridging agent, copper ion bridging ion and xanthate bridging collecting agent; adsorbing polyatom on the surface of the combined copper disseminated body through macromolecule bridging agent ion; re-adsorbing copper ion on bridging agent, wherein the bridging agent is adsorbed on the surface; adsorbing a collecting agent xanthate negative ion on bridging copper ion; and dewatering the surface of the combined copper disseminated body, thus achieving the effective flotation. In the method, the macromolecule bridging agent is of polyatom adsorption ability, therefore, adsorption strength of the bridging agent on the surface of the combined copper disseminated body can be greatly improved, the copper ion is utilized as bridging ion, and mineral, bridging agent molecule and collecting agent xanthate molecule are connected together, so that collecting agent xanthate can be indirectly adsorbed on the surface of the combined copper disseminated body, and flotation recycling of the combined copper disseminated body which can not be floated and recycled can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

Thermometal compound flat wire

InactiveCN103400640ALow costShort processNon-insulated conductorsFlat/ribbon cablesElectrical conductorCopper wire

A thermometal compound flat wire is manufactured by the compounding of core layer metal of modified aluminium alloy and coating layer metal of copper, and is characterized in that interfaces of the core layer metal of the modified aluminium alloy and the coating layer metal of the copper are in metallurgical bonding; the purity of the copper is 99.95%-99.99%; the proportional range of the cross-sectional area of the coating layer metal of the copper is 15%-30%; the width of the copper-coated rare earth aluminum alloy flat wire is 30-200 mm, and the width-to-thickness ratio is 30:1. According to the flat wire, the interfaces of the copper and the aluminium reach the metallurgical bonding; the technological process is short, the production efficiency is high, and the product cost is low; the flat wire is suitable for large-scale and normalized industrial production; the length ratio of the flat wire to a pure copper wire is 2.5:1, namely, 1.58 ton pure copper can be saved when 1 ton copper-coated modified aluminium alloy compound conductor material is produced, so that the copper resource is effectively saved; the cost of downstream industry product is lowered.

Owner:丹阳利华电子有限公司

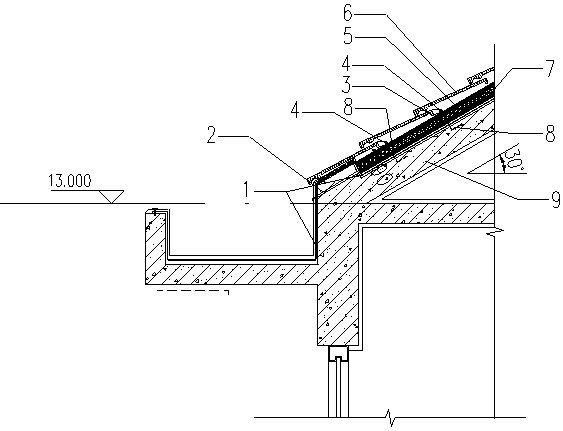

Fixing method for ceramic tile

InactiveCN108442617AAdvantages of fixed methodSimple structureRoof covering using tiles/slatesBuild-up roofsForeign matterCopper wire

Provided is a fixing method for a ceramic tile suitable for the range of inclination angles from 20 degrees to 45 degrees of a slope roof. The construction process follows the sequence of a pre-embedded steel bar in a structure layer, a water-proof layer, a heat-preserving layer, a leveling layer, a tile-laying layer, fixation of the ceramic tile and cleaning. The construction process comprises the following steps: a, laying the structure layer; b, laying the water-proof layer; c, laying the heat-preserving layer; d, laying the leveling layer; e, laying the tile-laying layer; f, fixing the ceramic tile; g, cleaning waste and foreign matter on the surface of a surface of the ceramic tile in order to keep the surface of the ceramic tile clean and bright. The fixing method for the ceramic tile has a fixing structure of the ceramic tile. The structure is simple and the ceramic tile is convenient to manufacture. A pre-embedded steel bar head is combined with a binding copper wire in order to fix the ceramic tile. The project quality is safe and reliable. The construction speed is high. The construction is simple and convenient. In addition, the ceramic tile is firmly fixed with a basiclayer in order to prevent the tile from falling down. The fixing method is advantaged by being excellent in waterproofness and helps reduce project cost.

Owner:MCC5 GROUP CORP SHANGHAI

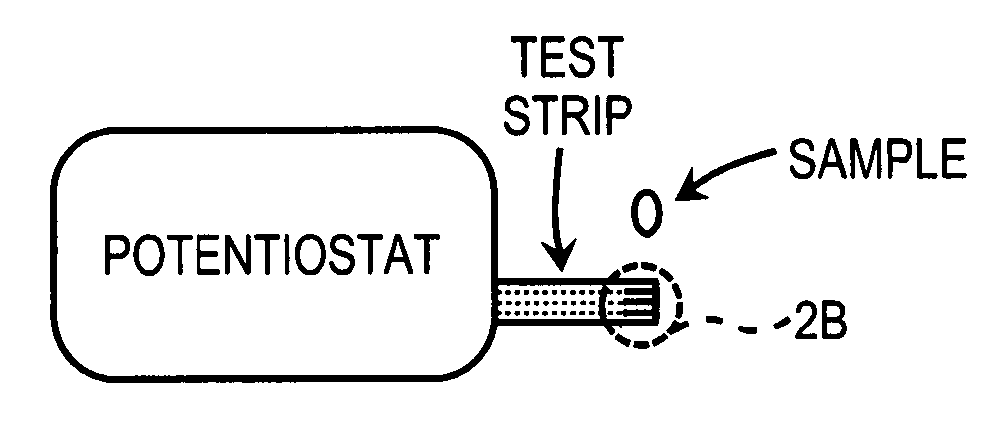

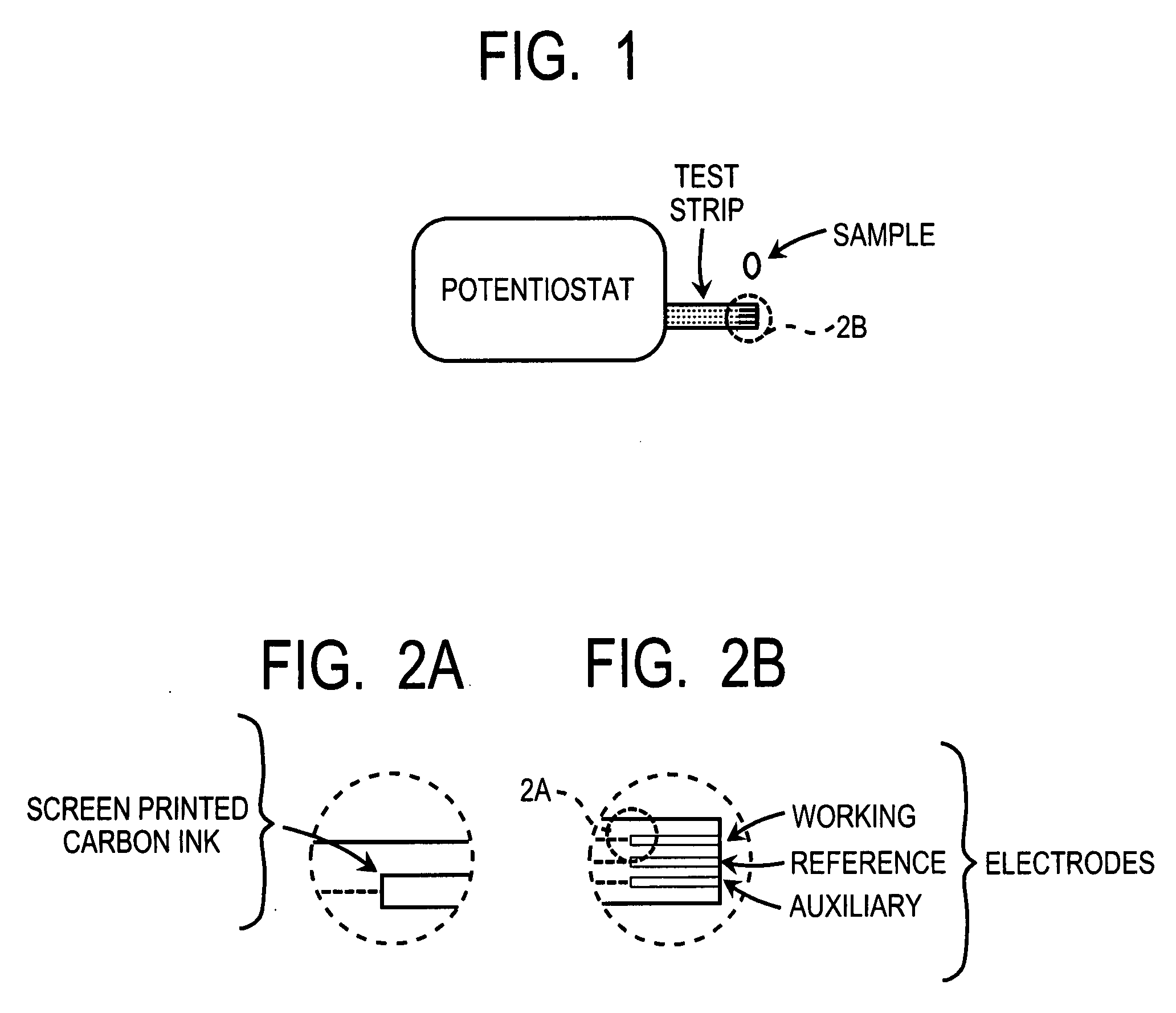

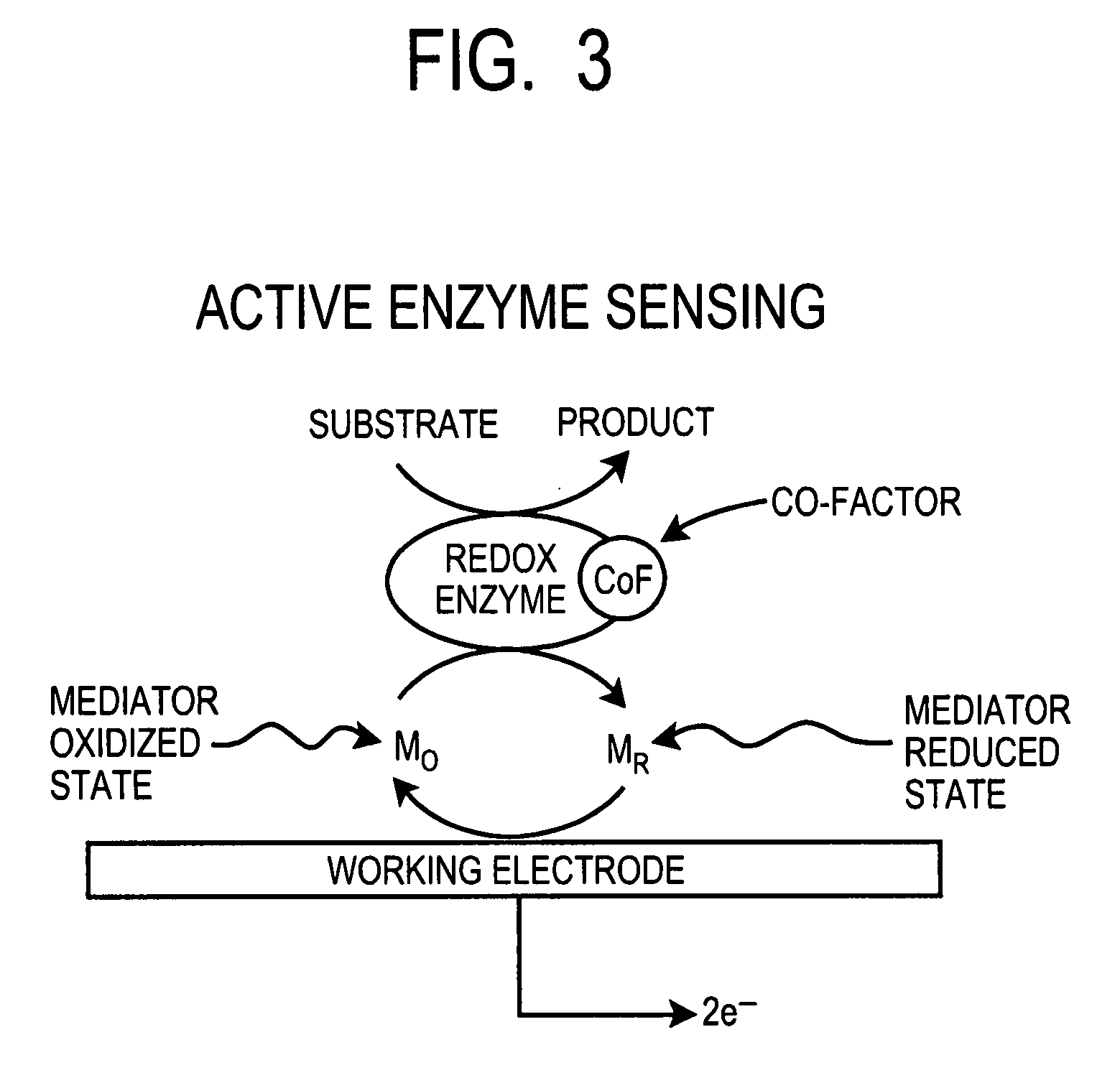

Methods and devices for the detection and measurement of free metals in fluids and methods for diagnosing metal-related diseases and for determining pharmacologic dosing regimens

InactiveUS20070209950A1Low costImmobilised enzymesBioreactor/fermenter combinationsPoint of careRegimen

A detection method or a method for a point of care diagnostic assay which comprises detecting non-covalently bound copper (free copper) concentrations in a fluid.

Owner:PIPEX

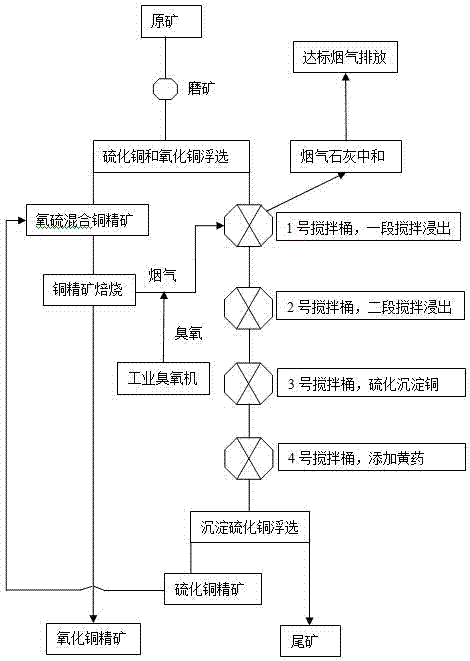

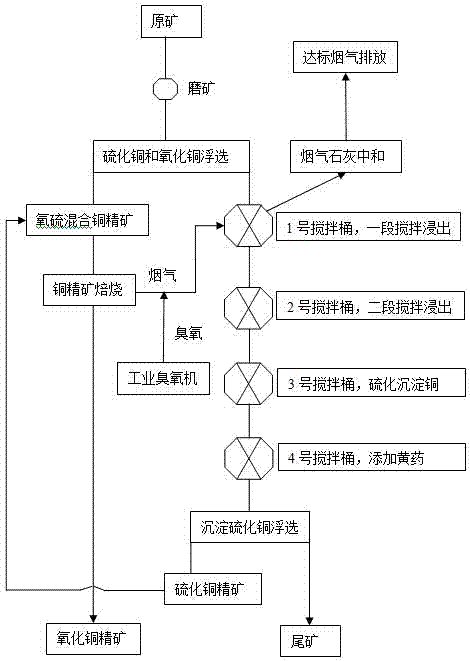

Beneficiation method of mixed copper ore having low oxidation rate and high binding rate

The invention discloses a beneficiation method of mixed copper ore having a low oxidation rate and a high binding rate. With the respect to sulfide-oxidized mixed copper ore having a low oxidation rate and a high binding rate, copper sulphide ore and free copper oxide ore in the sulfide-oxidized mixed copper ore are recovered through floatation, flotation concentrate is subjected to desulphurizing roasting and copper oxide concentrate is obtained, roasting flue gas is used for leaching out refractory copper oxide and binding copper in flotation tailings, then copper ions in ore pulp are leached out by sodium sulfide sediment tailings and copper sulphide sediment is obtained, xanthate is added for the floatation of the copper sulphide sediment and copper sulphide concentrate is obtained, the cupric sulfide concentrate and sulfide-oxidized mixed copper concentrate are mixed, then a mixture is subjected to the desulphurizing roasting and final copper oxide concentrate is obtained. According to the method, the low-grade tailings are leached out by sulfur dioxide generated by sulfur in the concentrate of the mixed copper ore, refractory free copper oxide and bound copper, which are difficult to recover, in the flotation tailings are recovered, the cost is low, and a comprehensive recovery rate of copper is raised significantly.

Owner:KUNMING UNIV OF SCI & TECH +1

Liquid nutritional products comprising metal amino acid chelates

InactiveUS20140037798A1Reduce catalytic activityExtended shelf lifeOrganic chemistryCocoaVitamin CVitamin A Alcohol

Disclosed are shelf stable nutritional liquids including metal amino acid chelates. Metal amino acid chelates, such as copper amino acid chelates and iron amino acid chelates, limit the capacity of incompletely bound copper and iron to catalyze the oxidation of sensitive nutrients such as vitamins, particularly vitamin A, vitamin B12 and vitamin C, thereby imparting both nutritional benefits and sensory benefits to the nutritional liquids.

Owner:ABBOTT LAB INC

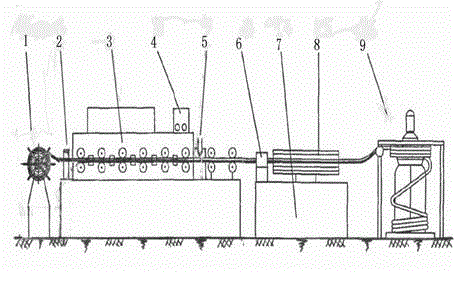

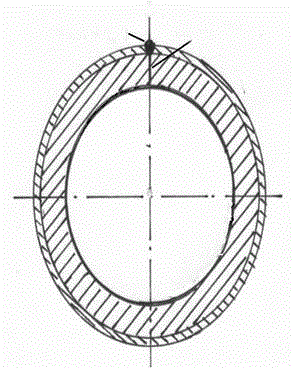

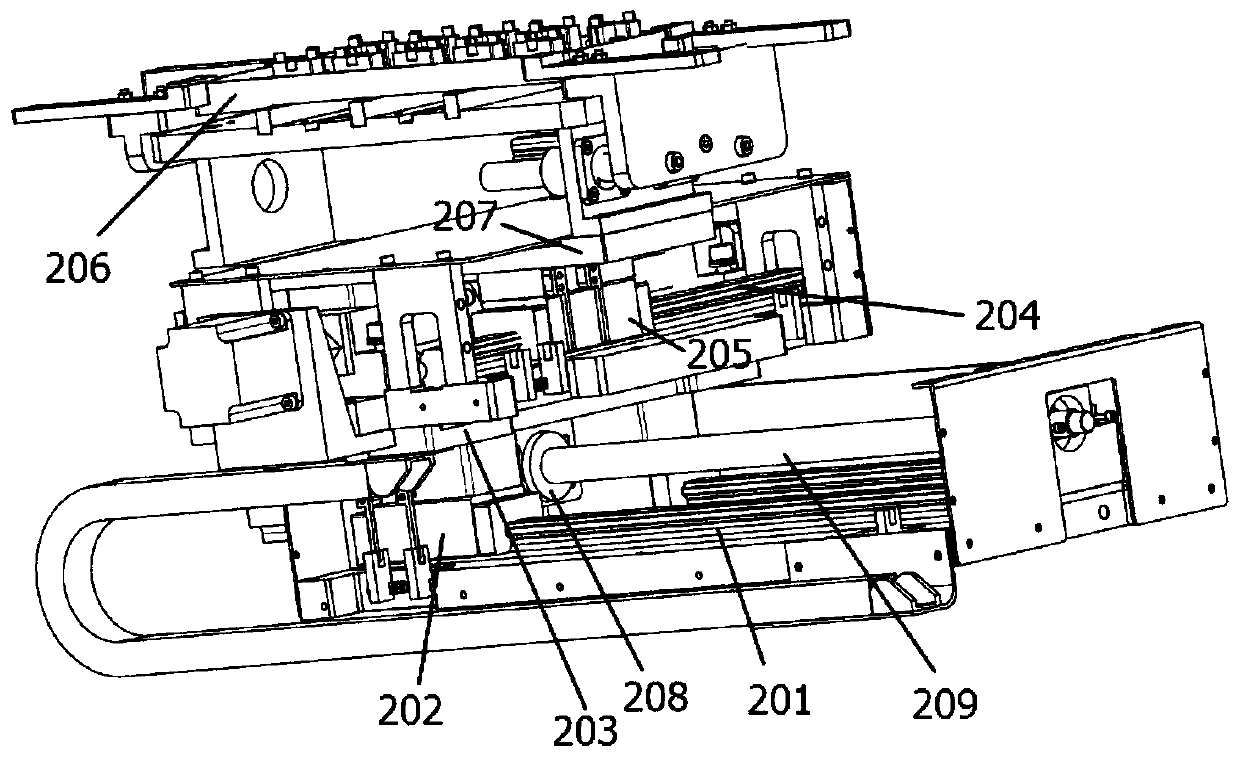

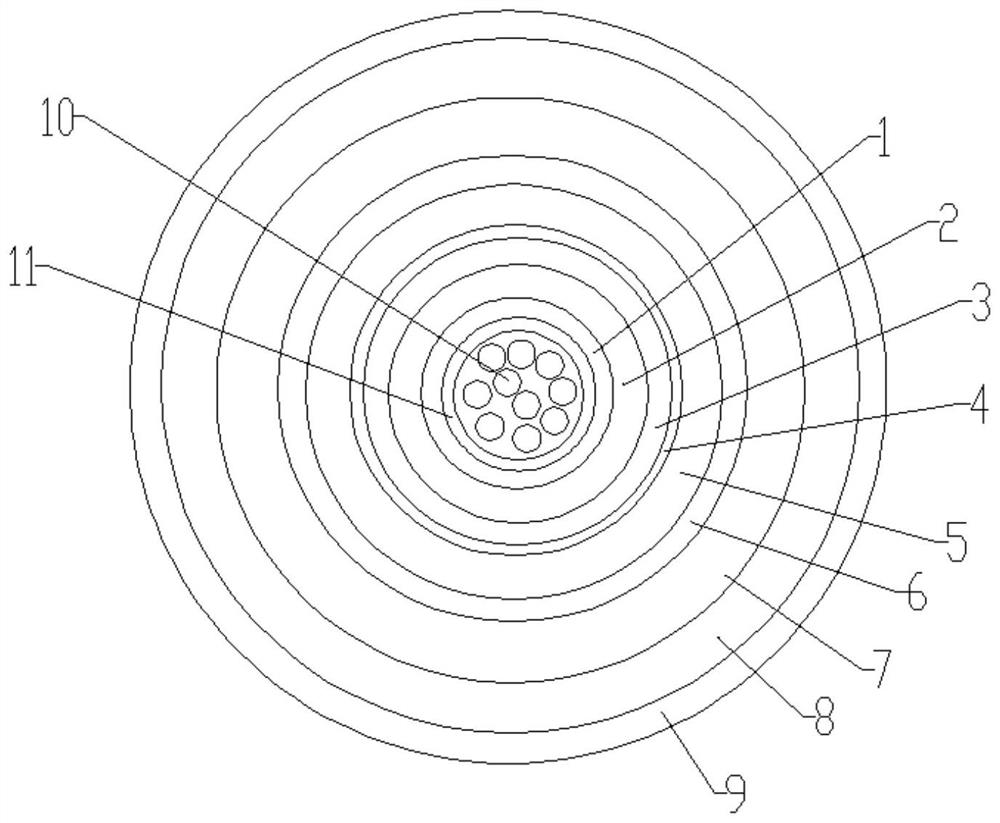

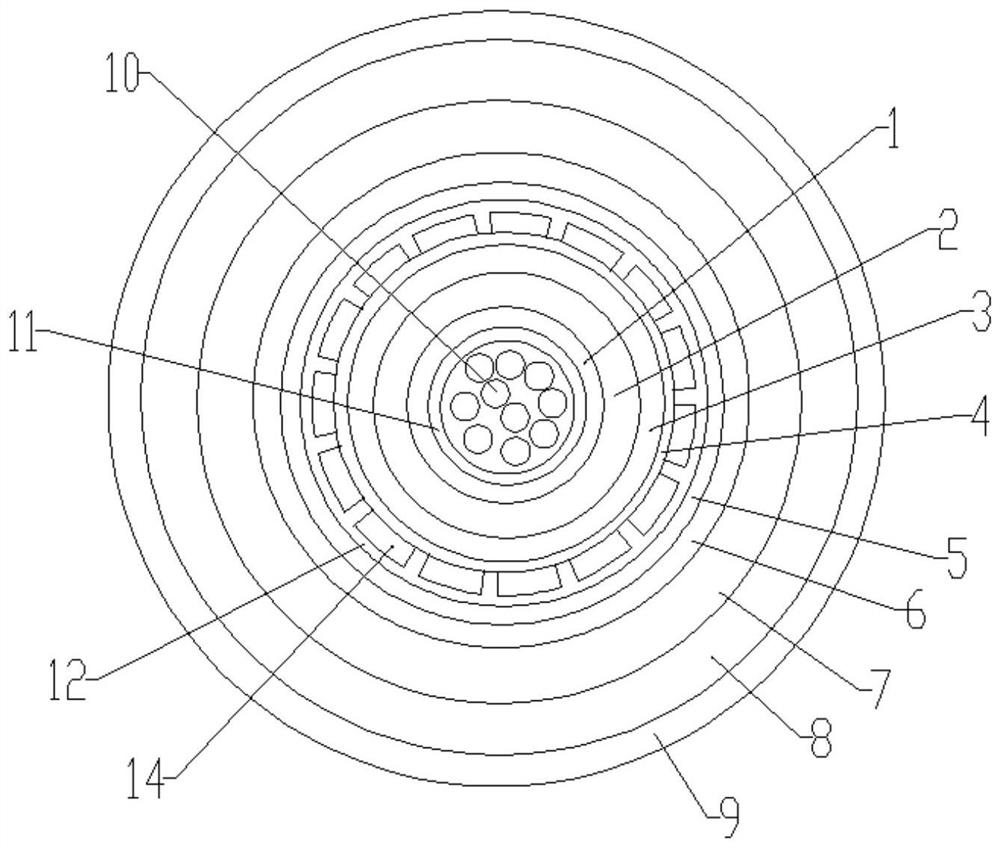

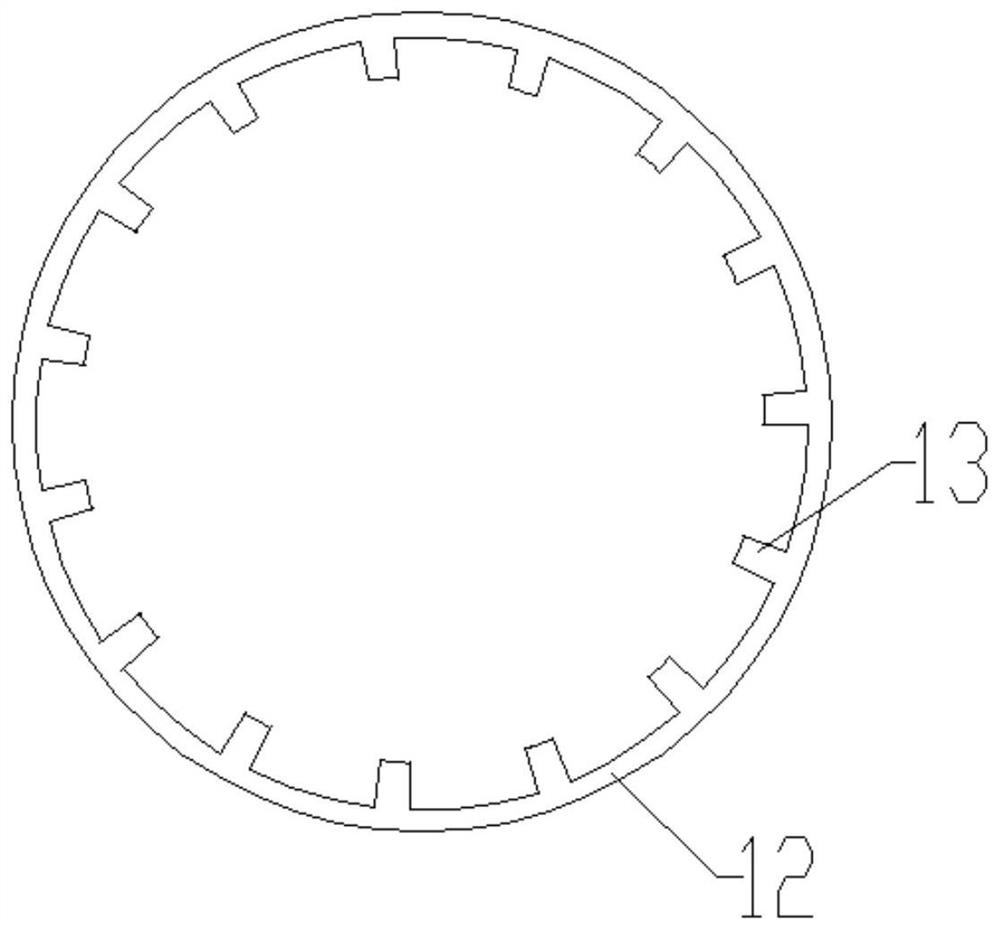

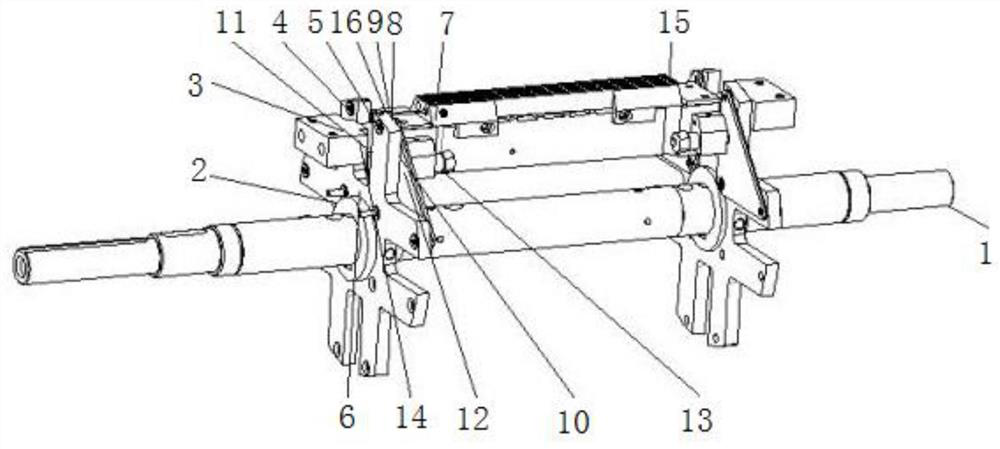

Method for producing copper-clad aluminum pipe and used production line

ActiveCN102982903AReduce weightReduce loadCable/conductor manufactureProduction lineElectrical conductor

The invention relates to a structure, production method and production line of a copper-clad aluminum pipe of a coaxial cable inner conductor for transmitting radio-frequency signals. The copper-clad aluminum pipe is rolled into a round pipe with a copper aluminum composite belt, a longitudinal joint of a copper layer is welded by argon-arc welding, an aluminum layer adjoining plane is pressed by drawing, and metallurgical bonding is formed by means of atomic diffusion in the annealing process. The copper-clad aluminum pipe production line is composed of a copper aluminum composite belt material plate (1), an aluminum layer two-end planing cutting groove device (2), a copper-clad aluminum pipe forming device (3), an argon arc welding machine (4), a welding gun (5), a wire drawing die (6), a wire drawing machine (7), a drawing large plate (8) and a pipe blank wire-collecting device (9) and the like. Power transmitted by each device process of the production line is all driven by the wire drawing machine, so that the moving speeds of the processes of each part of the whole production line are consistent.

Owner:大连通发诚信科技有限公司

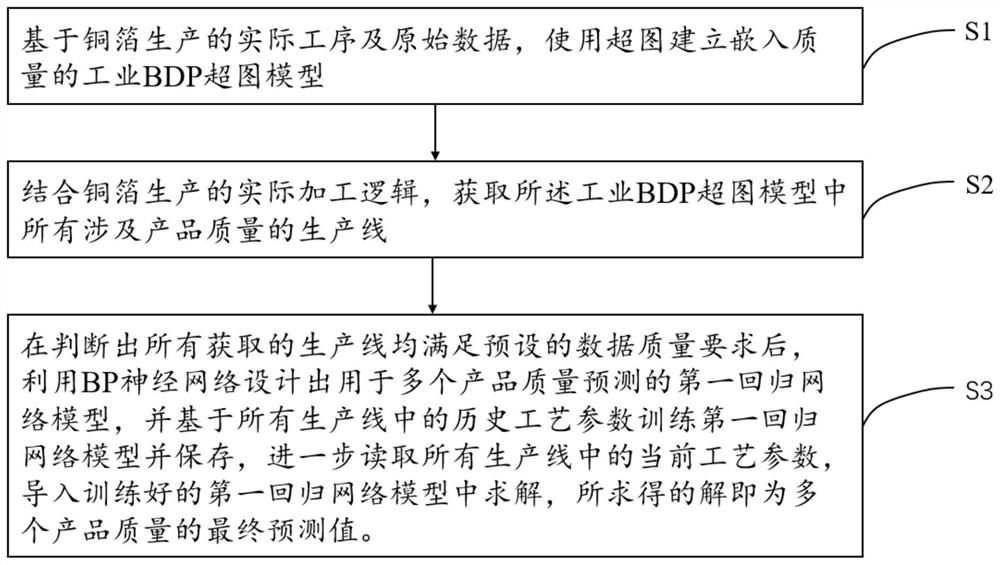

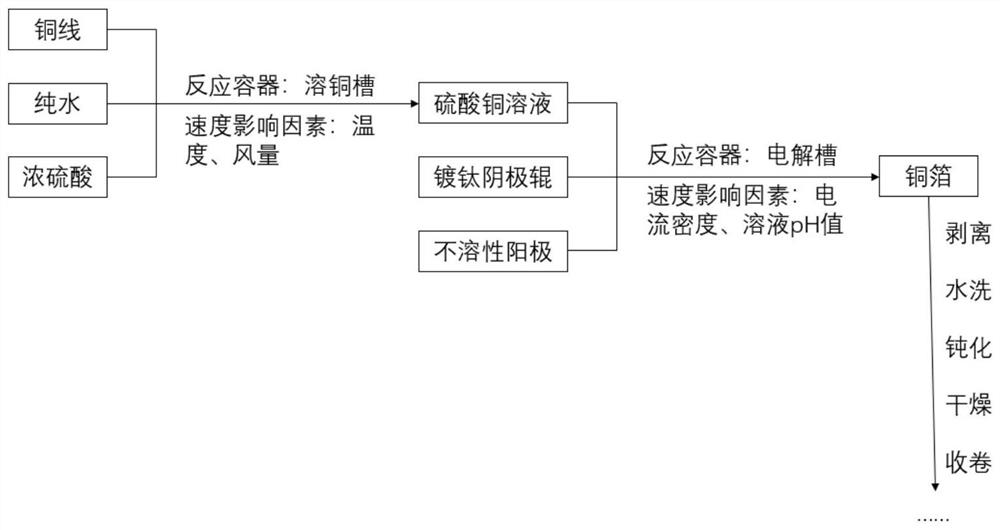

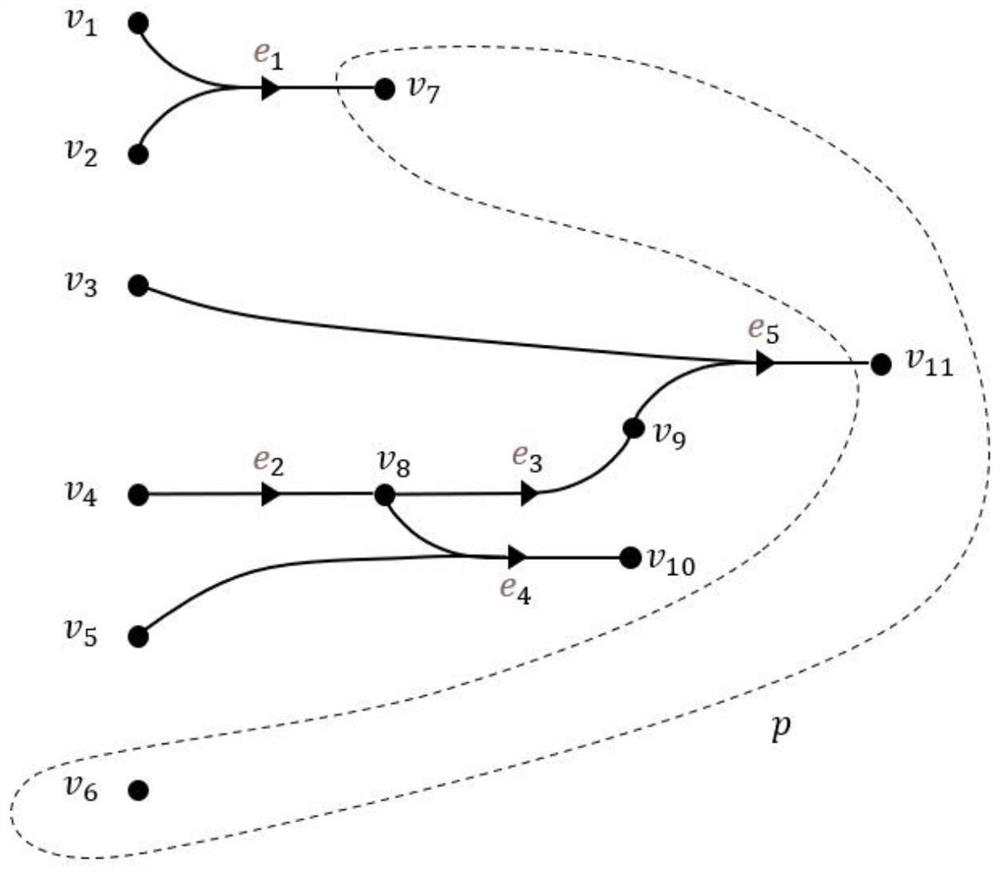

Product quality prediction method and system for industrial copper foil production

ActiveCN113705897AAchieve optimizationAccurate predictionForecastingCharacter and pattern recognitionOriginal dataProcess engineering

The invention provides a product quality prediction method for industrial copper foil production, and the method comprises the steps: building an embedded quality industrial BDP hypergraph model through a hypergraph based on the actual process and original data of copper foil production; obtaining all production lines related to product quality in the hypergraph model in combination with actual processing logic of copper foil production; after judging that all the obtained production lines meet the data quality requirements, designing a first regression network model by utilizing a BP neural network, training and storing the first regression network model based on historical process parameters in all the production lines, and further reading current process parameters in all the production lines, and importing into the trained first regression network model for solving, wherein the obtained solution is the final predicted value of the quality of the plurality of products. By implementing the method, the transmission, processing and quality solving of the process parameter data can be successfully expressed, the accurate prediction of the product quality is realized, and the optimization of the process parameters can be further realized.

Owner:JIANGXI XINBORUI TECH CO LTD

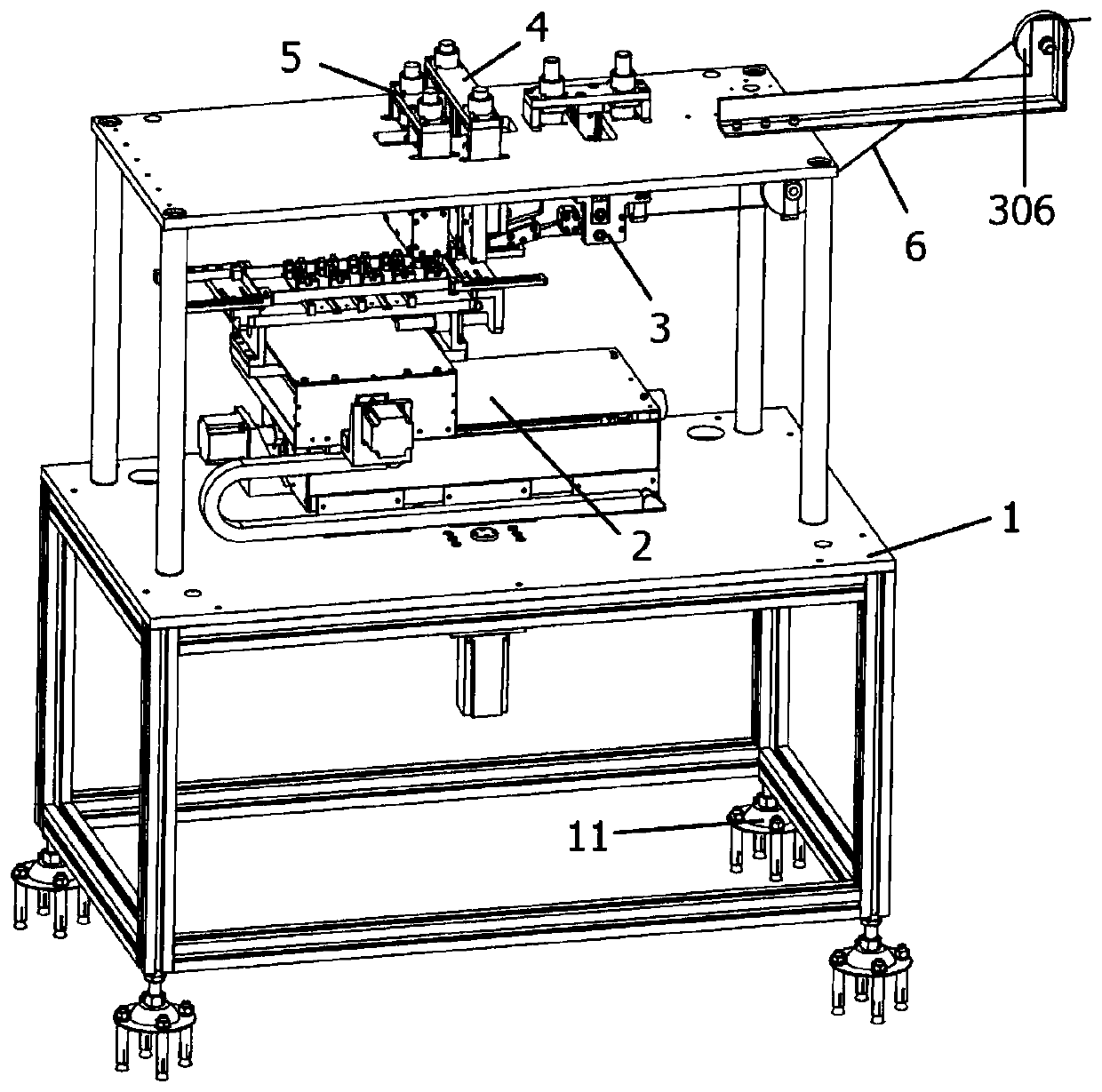

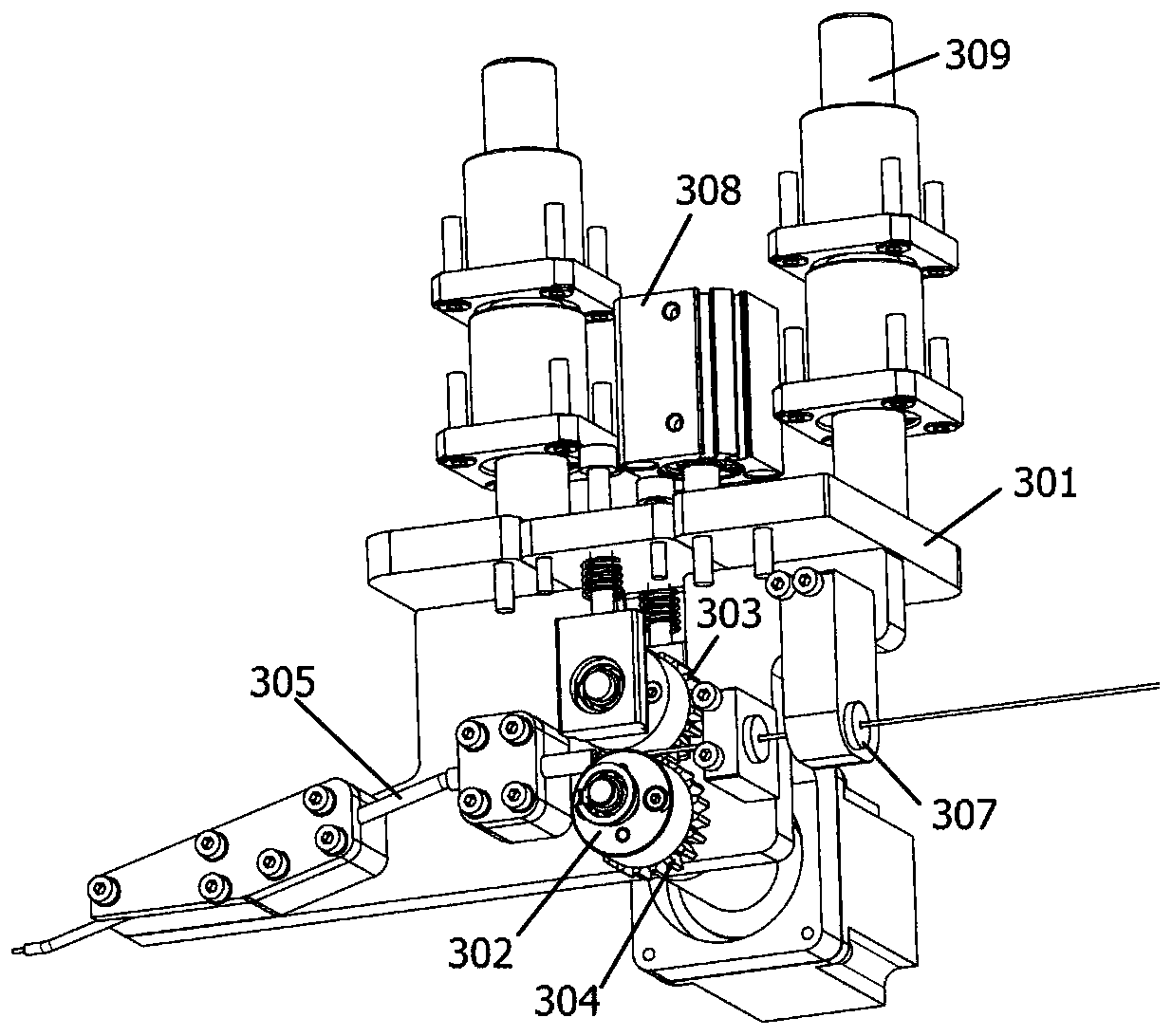

Automatic welding device and control method

PendingCN111014921AHigh degree of automationLow costResistance welding apparatusCopper wireEngineering

The invention belongs to the technical field of welding processing and discloses an automatic welding device and a control method of the automatic welding device. The automatic welding device comprises a rack, wherein a platform, a wire feeding mechanism, a spot welding mechanism and a cuttoff mechanism are arranged on the rack; the platform can move in the X-axis direction and the Y-axis direction and rotate in the Z-axis direction, and an object to be welded is arranged on the platform; the wire feeding mechanism is used for conveying a copper wire to the object to be welded; the spot welding mechanism is used for welding the object to be welded in combination with the copper wire; and the cutoff mechanism is used for cutting off the copper wire. According to the automatic welding device, full automation of welding is realized, physical injury to operators caused by welding is avoided, labor cost is reduced, and the intelligent level of the whole device is improved.

Owner:SHANGHAI UNIV OF ENG SCI

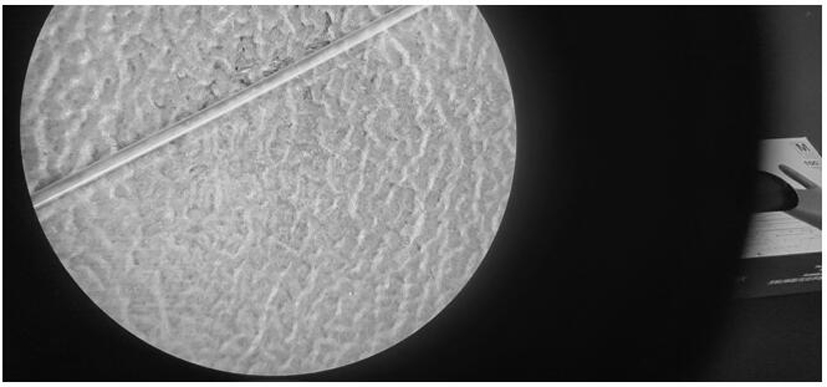

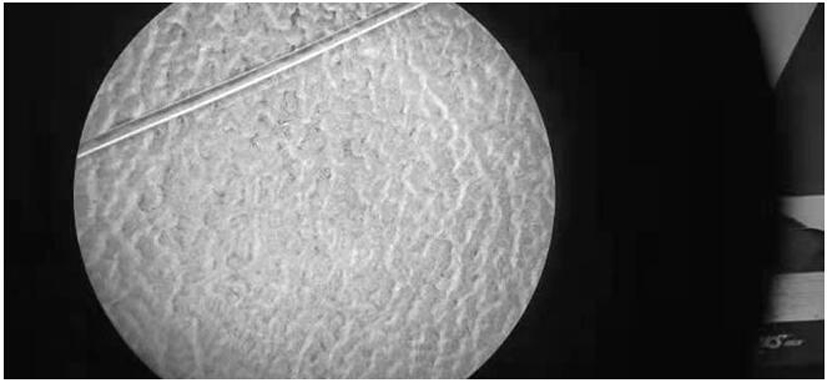

Grinding wheel for roughing and thinning mobile phone backboard glass and preparation method of grinding wheel

PendingCN114378730AImprove control abilityExtend your lifeAbrasion apparatusGrinding devicesEpoxyTitanium alloy

The invention belongs to a thinning tool, and particularly relates to a grinding wheel for roughing and thinning mobile phone backboard glass and a preparation method of the grinding wheel. Diamond, epoxy resin and copper-tin-titanium alloy powder are mixed, and diamond particles wrapped with the alloy powder are obtained; then mixing the diamond particles wrapped with the alloy powder with the ball-milled metal matrix to obtain a material; and the material is subjected to cold pressing and sintering, and the grinding wheel for roughing and thinning the mobile phone backboard glass is obtained. According to the grinding wheel for roughing and thinning the mobile phone backboard glass, the diamond is subjected to surface brazing pretreatment, the holding performance of a binding agent on the diamond is improved, meanwhile, cobalt is added to be combined with copper and tin for modification, good sharpness and deformation resistance are achieved, and the service life of the grinding wheel for roughing and thinning the mobile phone backboard glass can be greatly prolonged in the aspect of practical application.

Owner:赛尔科技(如东)有限公司

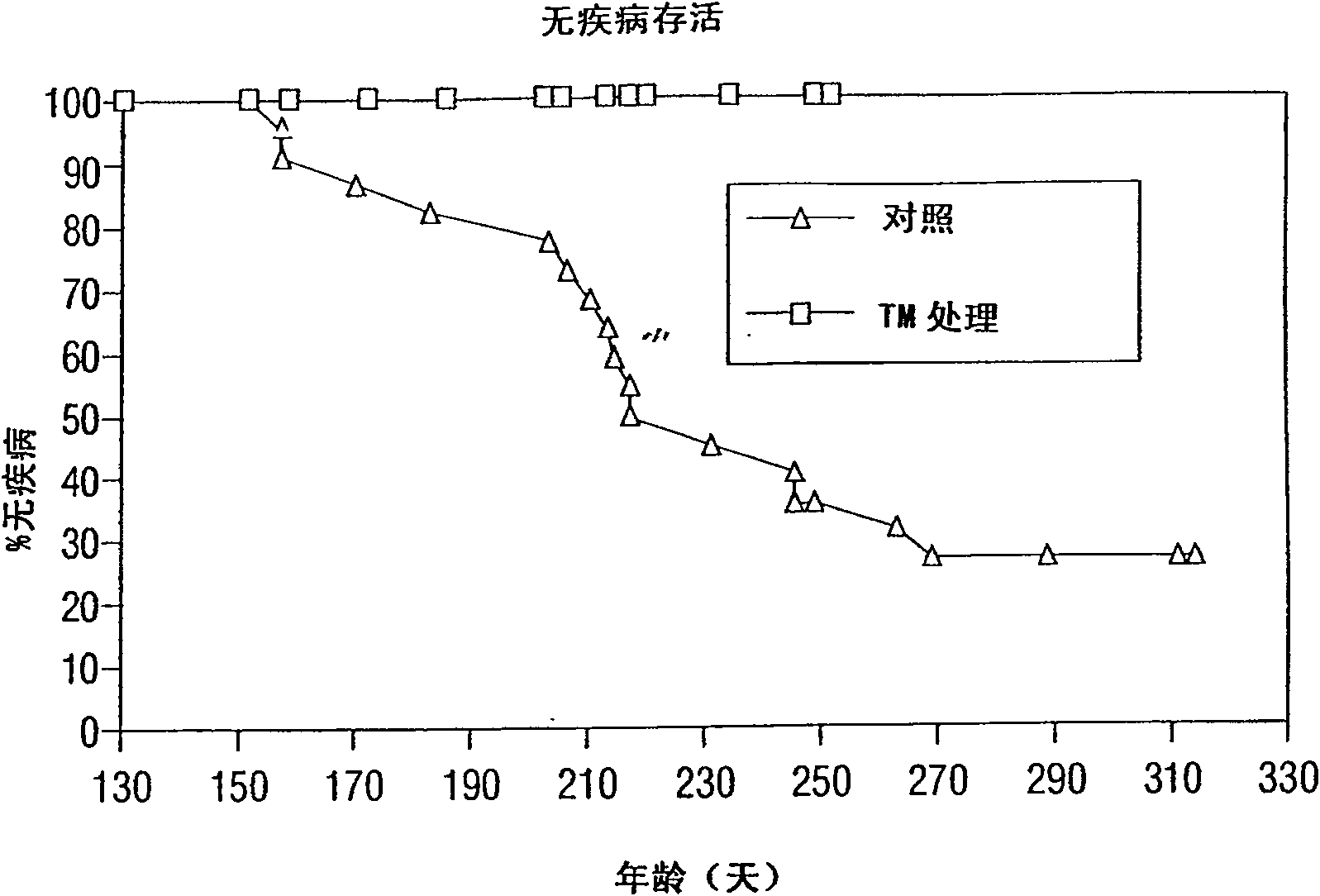

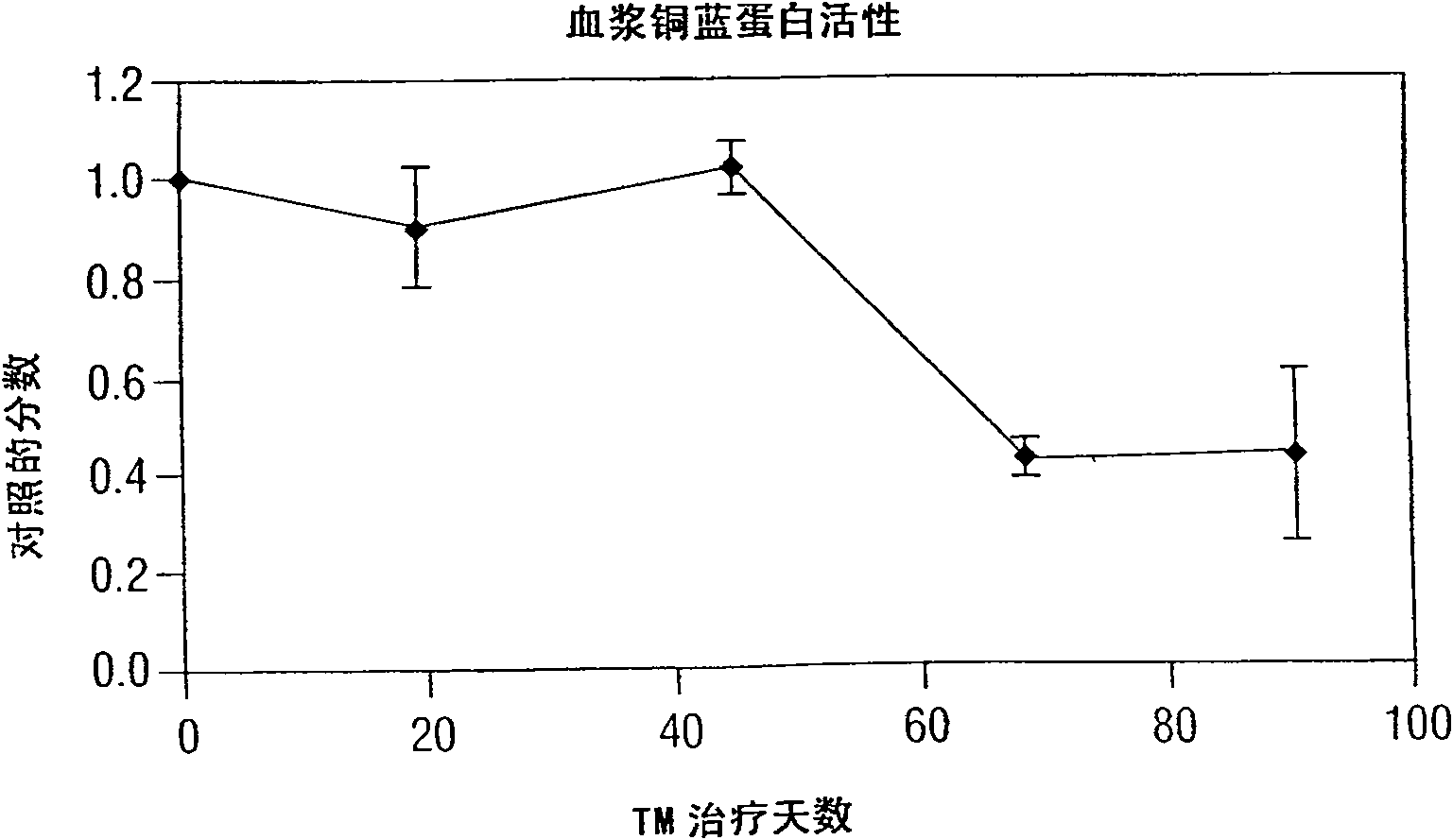

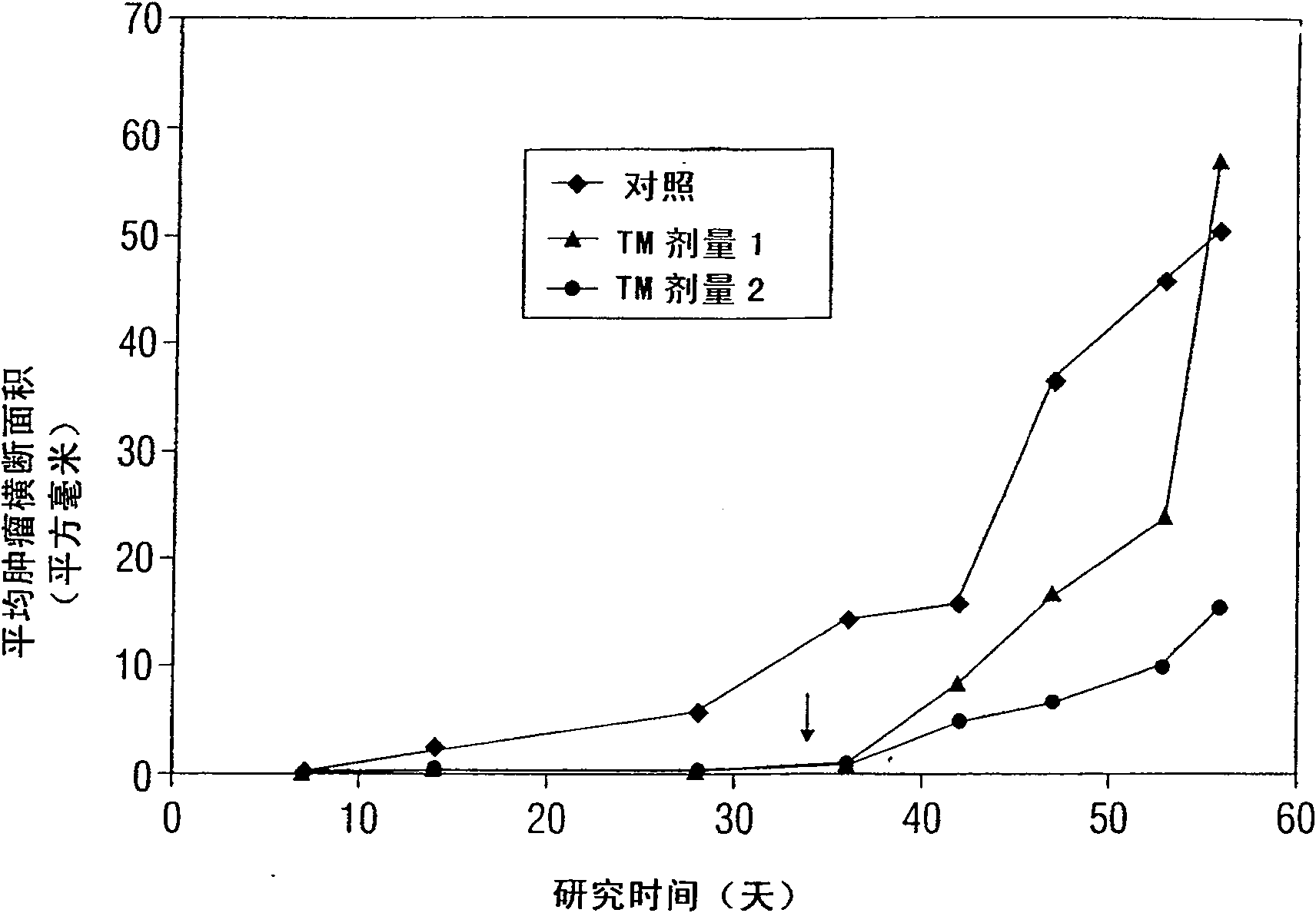

Method and compositions for prevention or treatment of cancer

InactiveCN100548383CLow level of toxicityMedicine works wellHeavy metal active ingredientsAntipyreticDiseaseMedicine

Provided are agents that can bind to copper, and form a tripartite complex with protein, and the use of these agents in the prevention and treatment of diseases with a vascular component, such as solid tumors. Compositions and methods for combination therapy of these diseases, including cancer, as well as therapeutic kits, are also provided.

Owner:RGT UNIV OF MICHIGAN

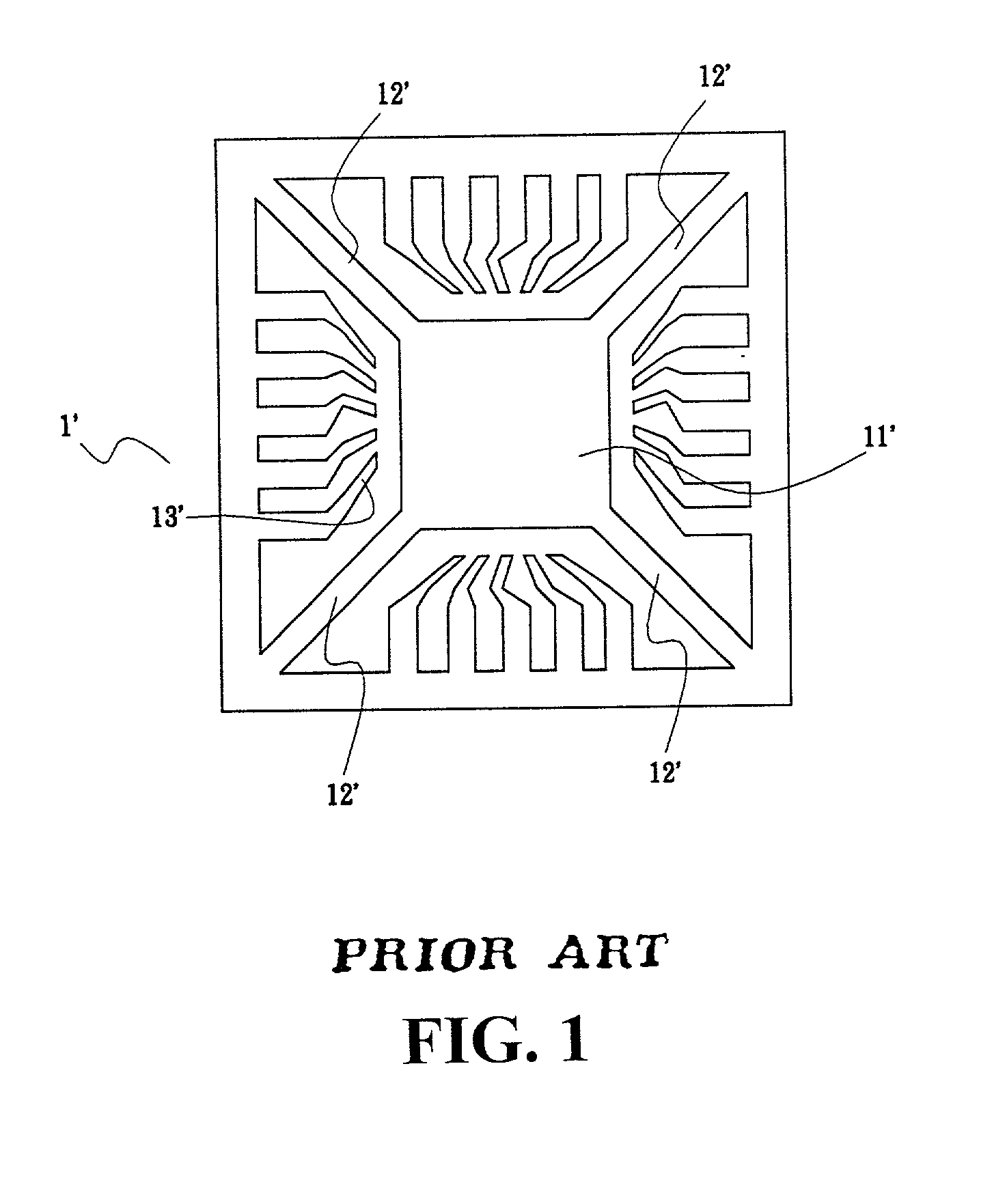

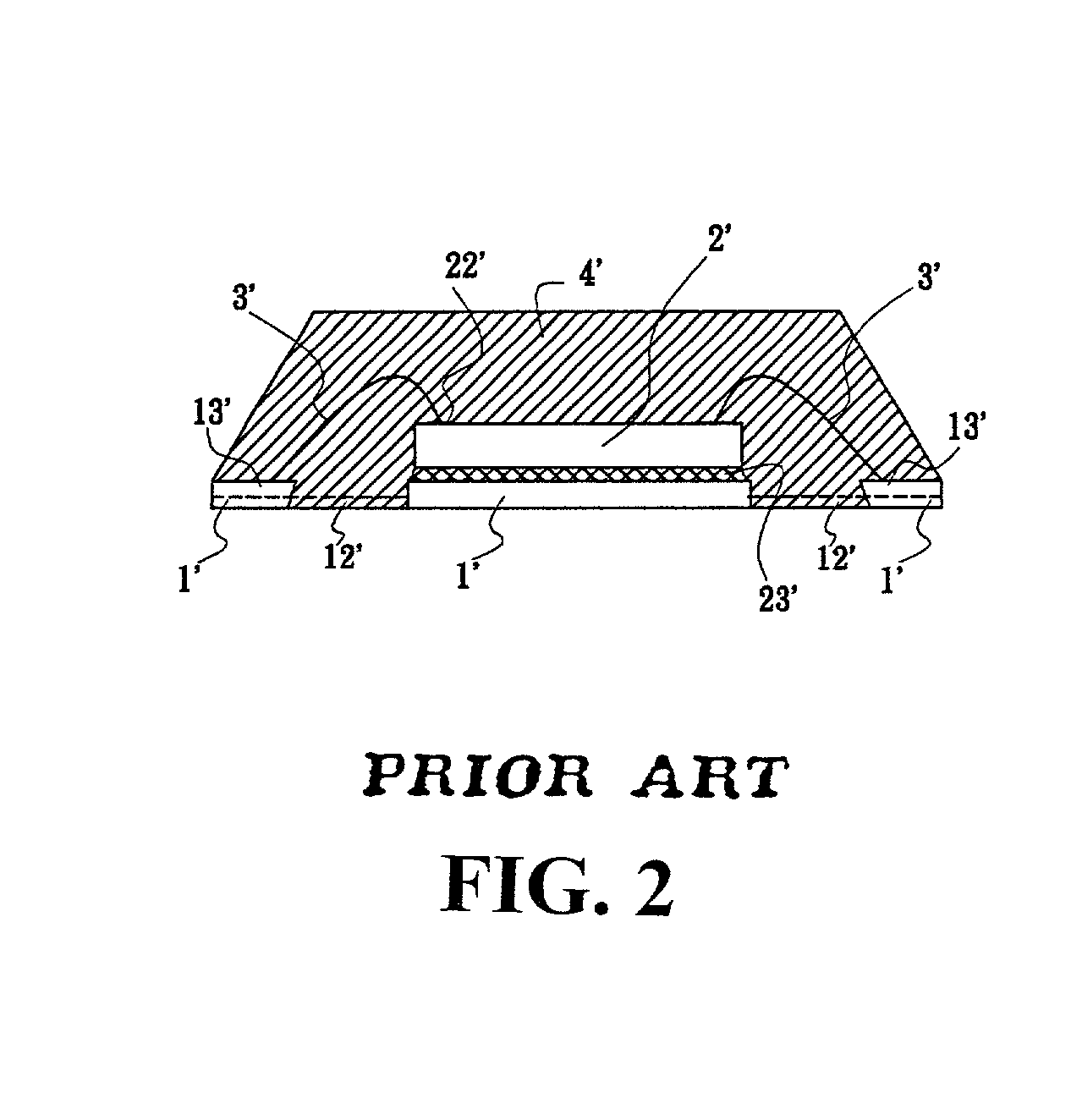

Fabrication method of semiconductor

A fabrication method of semiconductor packaging and the packaging element is disclosed. A layer of copper is formed on a thick heat-resistant tape and the surface of the copper layer is coated with a light sensitive photoresist. A light source passes through a pre-fabricated circuit negative being performed on the copper layer such that the photoresist is retained on the surface of the copper layer. An etching step is performed so as to obtain a copper wire with circuit diagram. After that, a wire bonding or a flip chip method is used to bind copper wire circuit with the chip. An appropriate packaging method is performed, a packaging element is obtained after the heat-resistant tape is removed.

Owner:ORIENT SEMICON ELECTRONICS

Enhanced leaching method for copper ore

InactiveCN113512647AImprove leaching recoveryShorten the leaching timeProcess efficiency improvementMining engineeringCatalytic oxidation

The invention discloses an enhanced leaching method for copper ore, and relates to the field of hydrometallurgy. In the leaching process of complex copper ore containing sulfur, arsenic and combined copper, a composite catalytic oxidizing agent and an activating agent with super-strong oxidizing capacity are added, and the copper ore is leached in cooperation with acid leaching agent dilute sulphuric acid or alkaline leaching agent ammonia water, ammonium salt and the like. Due to the enhanced oxidation effect of the catalytic oxidizing agent and the activating agent, arsenic-sulfur minerals can be subjected to an oxidation reaction at high temperature and high pressure under normal temperature and normal pressure, so that the refractory copper ore is oxidized and leached. Therefore, the leaching rate is improved, and better economic benefits are obtained.

Owner:柯柏友

A kind of beneficiation method of mixed copper ore with low oxidation rate and high binding rate

A beneficiation method for a mixed copper ore with a low oxidation rate and a high binding rate. For an oxide-sulfide mixed copper ore with a low oxidation rate and a high binding rate, in the method, a copper sulfide ore and a free copper oxide ore therein are recovered by means of floatation, a floated ore concentrate is desulfurized by roasting to obtain a copper oxide concentrate, flue gas produced after the roasting is used for leaching out difficult-to-float copper oxide and bound copper in flotation tailings, then the tailings are precipitated by sodium sulfide to leach copper ions in ore pulp so as to obtain a copper sulfide sediment, a xanthate is added for floating the copper sulfide sediment to obtain a copper sulfide concentrate, the copper sulfide concentrate and an oxide-sulfide mixed copper concentrate are mixed, then a mixture is desulfurized by roasting, and a final copper oxide concentrate is obtained. According to the method, low-grade tailings are leached out by sulfur dioxide generated by sulfur in an ore concentrate, difficult-to-float free copper oxide and bound copper which are difficult to recover in flotation tailings are recovered, costs are low, and the comprehensive recovery rate of copper is improved significantly.

Owner:KUNMING UNIV OF SCI & TECH +1

Production process of industrial frequency transformer

The invention discloses a production process of an industrial frequency transformer. The production process comprises the following steps of: preparing required raw materials and equipment tools; starting to wind wires; binding copper wires; welding the copper wires to transformer pins; and assembling an iron core finished semi-finished product. According to the industrial frequency transformer manufactured through the process, the process is effectively simplified, meanwhile, the product quality is improved, the number of defective products is reduced, the service life of the transformer is prolonged, and the production efficiency is improved.

Owner:CHANGXING SHENGQIANG ELECTRONICS EQUIP

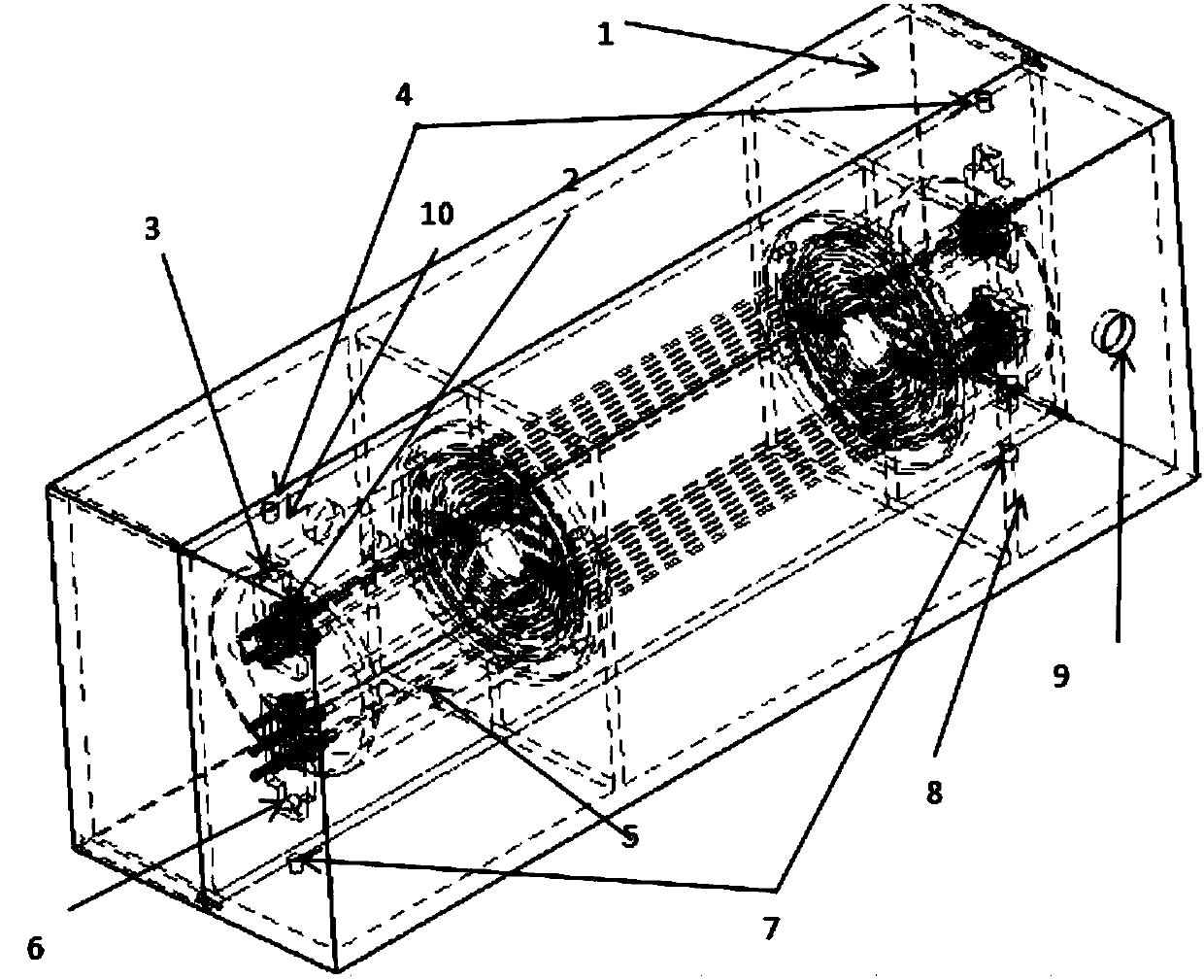

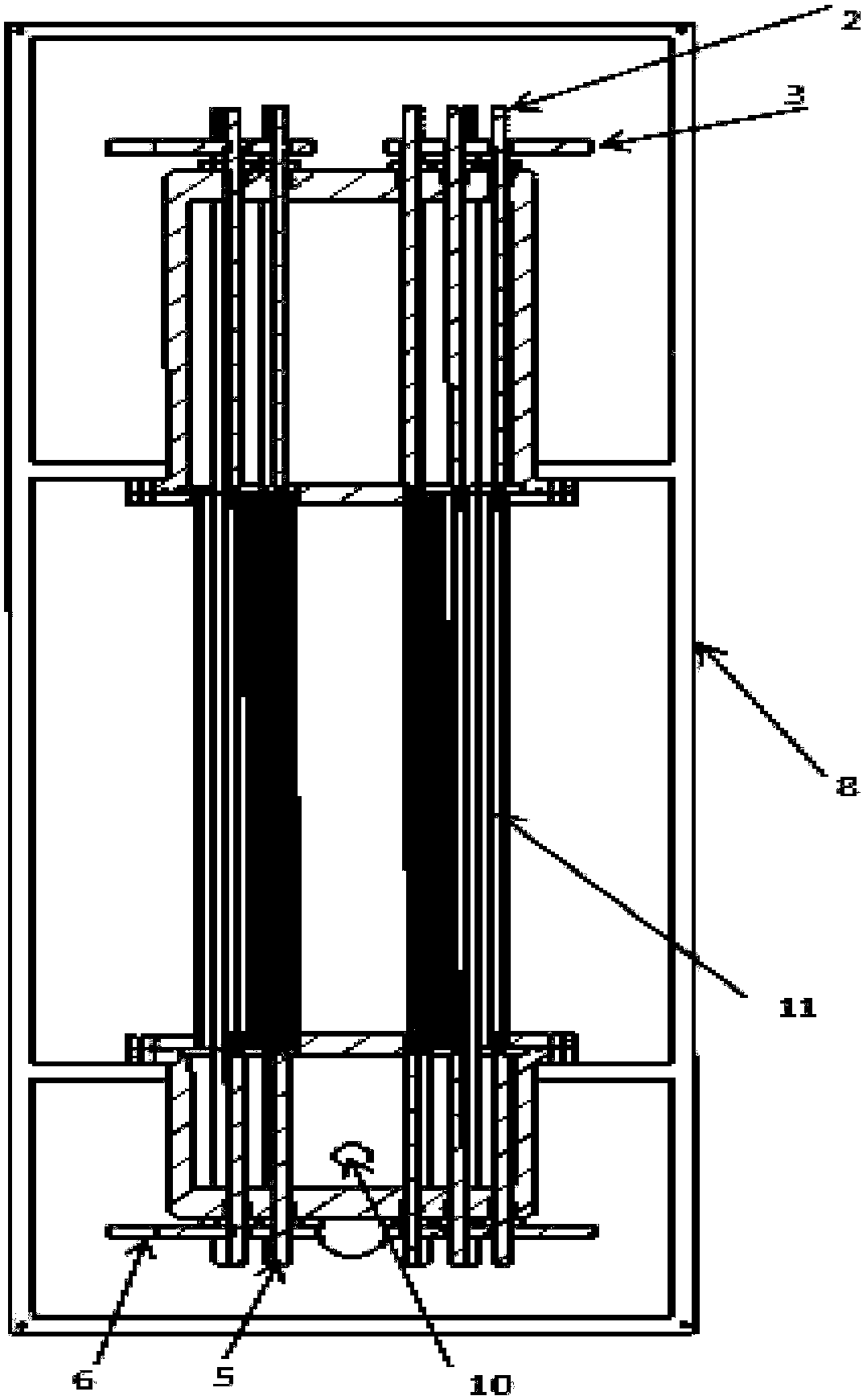

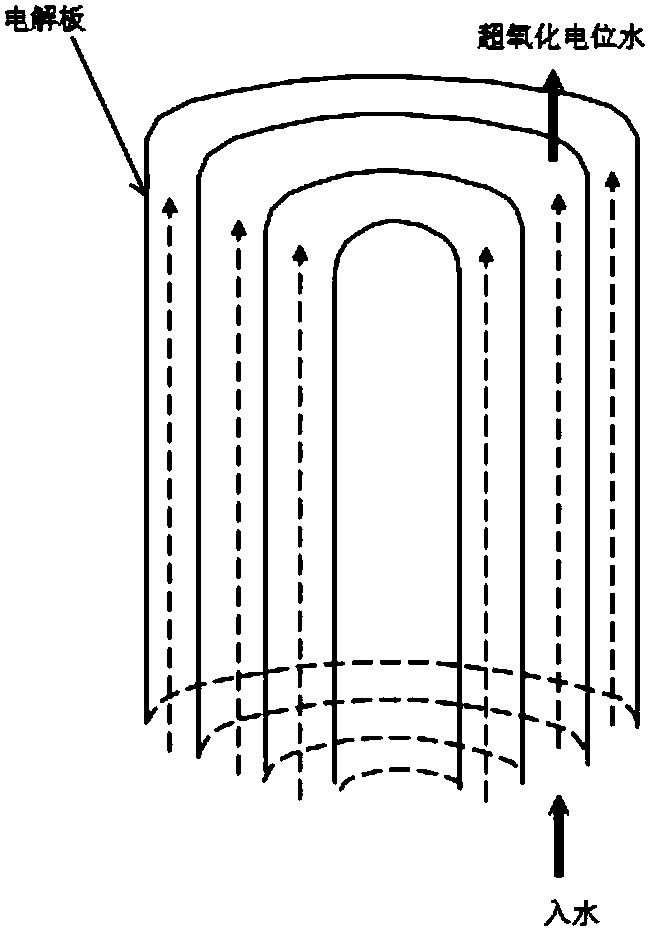

Electrolytic cell for over-oxidation potential water generator

InactiveCN107585832AReduce precipitation and scalingExtended service lifeWater/sewage treatmentOver oxidationCleansing Agents

The invention discloses an electrolytic cell for an over-oxidation potential water generator. The electrolytic cell comprises an electrolytic cell main body. A plurality of alternately arranged anodeand cathode electrode plates are arranged in the electrolytic cell main body. A gap is formed between the anode and cathode electrode plates. The anode and cathode electrode plates are rounded. Two ends of each one of the anode electrode plates are connected to anode binding posts. Two ends of each one of the cathode electrode plates are connected to cathode binding posts. The anode binding postsand the cathode binding posts are arranged on a binding copper bar. The binding copper bar is connected to an external electrolysis power supply through a port. The electrolytic cell is provided witha water inlet and a water outlet. The electrolytic cell has a simple structure, is easy to assemble, has a strong electrolytic capacity, realizes a low preparation cost, repeatedly utilizes main components, is free of a cleaning agent in the electrolysis process and satisfies environmental protection requirements.

Owner:烟台美珑机电科技有限公司 +1

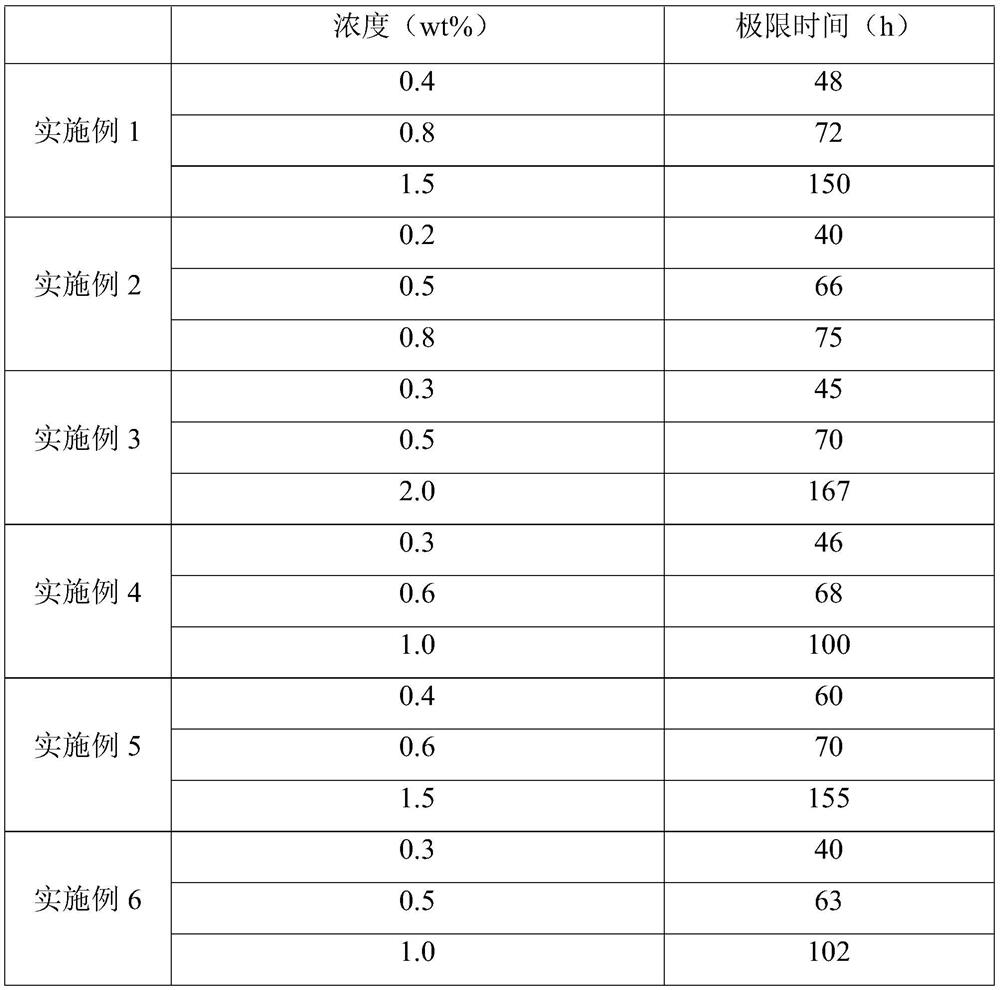

Copper wire drawing annealing liquid and using method thereof

PendingCN113549489AImprove antibacterial propertiesImprove the lubrication effectFurnace typesHeat treatment furnacesCopper wireBoronic acid

The invention relates to the technical field of copper wire drawing annealing, in particular to copper wire drawing annealing liquid and a using method thereof. The copper wire drawing annealing liquid is prepared from, by weight, 40-60 parts of copper antioxidant, 1-5 parts of solubilizer, 3-5 parts of boric acid, 5-10 parts of organic alcohol amine, 5-10 parts of antirust agent, 5-20 parts of self-emulsifying ester, 0.01-0.1 part of defoaming agent, 5-10 parts of bactericide and the balance water, and the total weight part of the copper wire drawing annealing liquid is 100. Compared with a traditional AB double-component wire drawing annealing solution, the copper wire drawing annealing liquid is more convenient to use, long in anti-oxidation time, good in lubricating property on an annealing cone pulley and not prone to abrasion, the single-component wire drawing annealing solution is high in antibacterial property, the service life of the single-component wire drawing annealing solution can exceed 6 months even under the concentration of 0.5%, wastewater discharge and treatment cost of the traditional double-component wire drawing annealing solution are reduced, the single-component annealing liquid is convenient and fast to use, errors are not prone to occurring, the oxidation resistance of the copper antioxidant and the lubricity of the wire drawing liquid are combined into a whole to the maximum extent, and management and control are convenient.

Owner:AMER TECH CO LTD

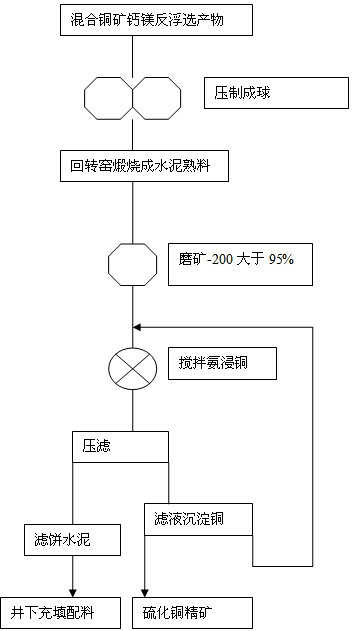

Comprehensive utilization method of reverse flotation products of calcium and magnesium carbonates in mixed copper ores

ActiveCN102690959AReduce dosageLower filling costsProcess efficiency improvementAluminatePhysical chemistry

The invention relates to a comprehensive utilization method of reverse flotation products of calcium and magnesium carbonates in mixed copper ores. The comprehensive utilization method comprises the following steps of: against the copper-containing products obtained by performing reverse flotation on the calcium and magnesium carbonates in the mixed copper ores, sequentially pressing to form pellets, calcining in a rotary kiln, grinding the ores and performing ammonia leaching to recover copper in the copper-containing products to obtain copper concentrate, and using the leached residue as ansubstitute for cement for filling ingredients in an underground goaf. According to the method disclosed by the invention, combined copper resources which can not be recovered by flotation, acid leaching and ammonia leaching can be effectively recovered, and the calcium and magnesium carbonates, silicates and aluminosilicates can be simultaneously transformed to the cement substitutes which can beused locally, so that the comprehensive utilization of the resources is realized, the filling cost in the goaf is lowered and the economic benefits are significant.

Owner:KUNMING UNIV OF SCI & TECH

Aluminum corrugated metal sheath fireproof cable for subway

PendingCN112768131AAvoid spreadingReduce releaseInsulated cablesInsulated conductorsGlass fiberCopper wire

The invention provides an aluminum corrugated metal sheath fireproof cable for a subway. The aluminum corrugated metal sheath fireproof cable comprises a conductive unit and a protective layer structure outside the conductive unit, wherein the protective layer structure comprises an insulating layer, an insulating shielding layer, a copper wire shielding layer, a reverse binding copper belt layer, a glass fiber belt wrapping tape layer, an inner sheath, an aluminum corrugated metal sheath, a fireproof mud layer and an outer sheath which are sequentially wrapped from inside to outside; and a discharge wire is arranged between the reverse binding copper belt layer and the glass fiber belt wrapping tape layer, and a buffer structure is arranged between the reverse binding copper belt layer and the glass fiber belt wrapping tape layer. The cable is reasonable in structural design, the sheath layer is made of a high-flame-retardant sheath material, and even if a fire occurs, the fireproof mud and the aluminum corrugated metal sheath are burnt and sintered to form a shell to prevent flame and heat from spreading into the cable, so that when the fire occurs, a power supply loop can be ensured to maintain normal work, the release amount of toxic and corrosive gas generated during cable combustion is extremely small, the flame-retardant effect is extremely good, and the concentration of generated smoke is extremely low.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

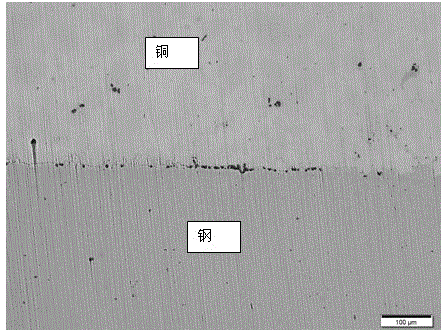

A copper-steel bimetal bridge welding method

InactiveCN103753042BEfficient weldingAchieve weldingWelding/soldering/cutting articlesWelding apparatusRoom temperatureHeating furnace

Owner:NORTHEASTERN UNIV LIAONING

High-speed end sealing wire structure

The invention belongs to the technical field of packaging mechanical equipment, and particularly relates to a high-speed end sealing wiring structure, one end of an external power line is fixed on a copper screw, the other end of the external power line enters an end sealing shaft through an inclined hole and then is connected with a collector ring, a carbon brush extends out under the action of elastic force and is attached to a copper plate, the external power line is connected with a heating pipe through the collector ring, the end sealing shaft, the copper screw, the copper plate, the carbon brush, a hollow copper stud and a copper block to achieve electric heating, in the operation process of equipment, only the carbon brush and the copper plate of a conductive part rub relatively, and the heating pipe, the external power line and a sealer do not move relatively, the external power line cannot leak electricity due to repeated bending, so that the problem of line breakage is solved; the structure is simple, active disconnecting is carried out at the position where the external power line easily generates relative motion, the carbon brush is connected with the copper plate, so that the carbon brush is always tightly combined with the copper plate when sliding on the copper plate, the external power line on one side of the copper plate is relatively static, and the external power line on one side of the carbon brush is also relatively static.

Owner:青岛松本包装机械有限公司

Anti-corrosion treatment process for anti-corrosion alloy pipe

ActiveCN112893062AImprove bindingReduced corrosion resistanceGeneral water supply conservationPretreated surfacesEpoxyAlloy

The invention discloses an anti-corrosion treatment process for an anti-corrosion alloy pipe. The anti-corrosion treatment process comprises the following specific machining processes that the surface of the alloy pipe is polished by adopting abrasive paper, then ultrasonic treatment is sequentially carrying out on the pipe for 5-6 minutes by using an acetone solution and absolute ethyl alcohol, then the pipe is soaked for 3-4 minutes by using a 1mol / L hydrochloric acid solution, the pipe is washed by using deionized water, and the pipe is dried for later use; the pipe is added into a surface treating agent solution with the concentration being 15% to be soaked for 5-6 min at the normal temperature, and the pipe is taken out and aired; and then a layer of epoxy resin anticorrosive paint is sprayed on the surface of the pipe. According to the anti-corrosion treatment process for the anti-corrosion alloy pipe, a metal surface is pretreated through a surface treating agent, then a coating is compounded, the surface treating agent is of a hyperbranched structure, the end group of the surface treating agent contains a large amount of oxysilane, sulfydryl and amino, silicon hydroxyl generated through hydrolysis of oxysilane bonds can be combined with hydroxyl on the surface of iron or aluminum metal in metal, and copper can be bonded with the sulfydryl, so that the binding capacity can be improved.

Owner:佛山市银正铝业有限公司

Macromolecule bridging flotation method for combined copper disseminated body

The invention provides a macromolecule bridging flotation method for a combined copper disseminated body, and aims to the combined copper disseminated body which can not be recycled through a conventional flotation manner. The method comprises the following steps of: adopting macromolecule bridging agent, copper ion bridging ion and xanthate bridging collecting agent; adsorbing polyatom on the surface of the combined copper disseminated body through macromolecule bridging agent ion; re-adsorbing copper ion on bridging agent, wherein the bridging agent is adsorbed on the surface; adsorbing a collecting agent xanthate negative ion on bridging copper ion; and dewatering the surface of the combined copper disseminated body, thus achieving the effective flotation. In the method, the macromolecule bridging agent is of polyatom adsorption ability, therefore, adsorption strength of the bridging agent on the surface of the combined copper disseminated body can be greatly improved, the copper ion is utilized as bridging ion, and mineral, bridging agent molecule and collecting agent xanthate molecule are connected together, so that collecting agent xanthate can be indirectly adsorbed on the surface of the combined copper disseminated body, and flotation recycling of the combined copper disseminated body which can not be floated and recycled can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

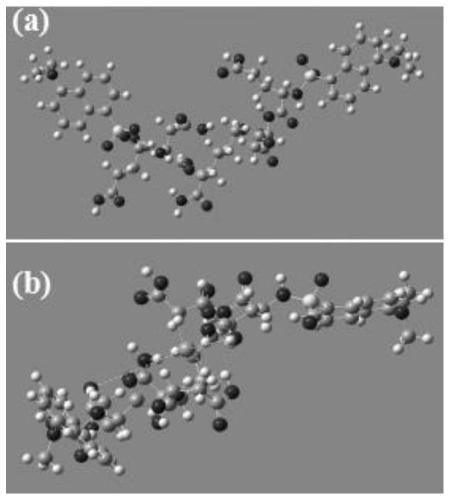

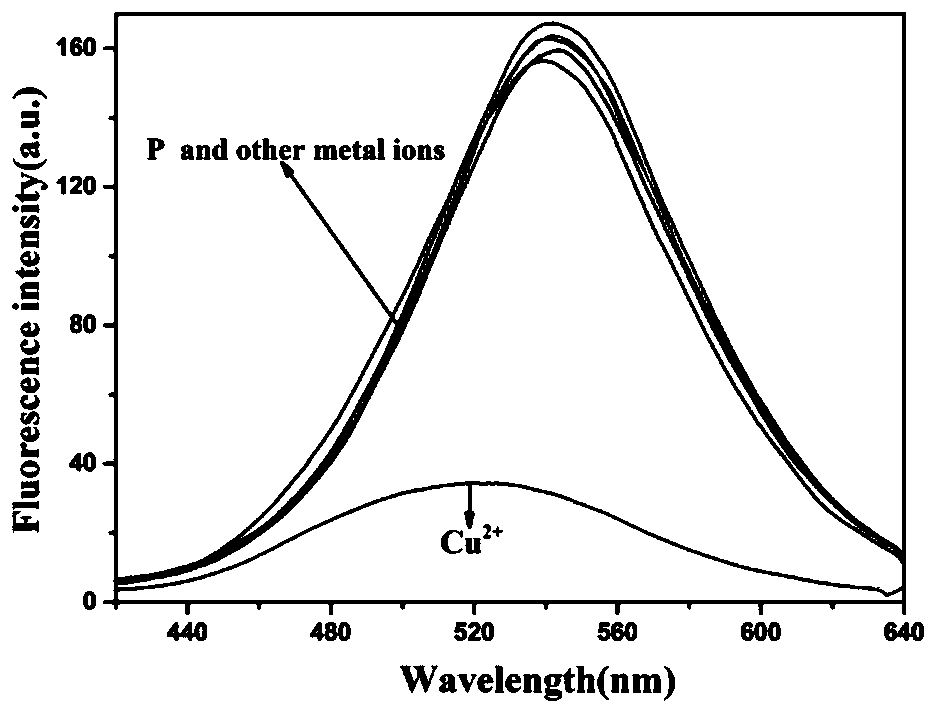

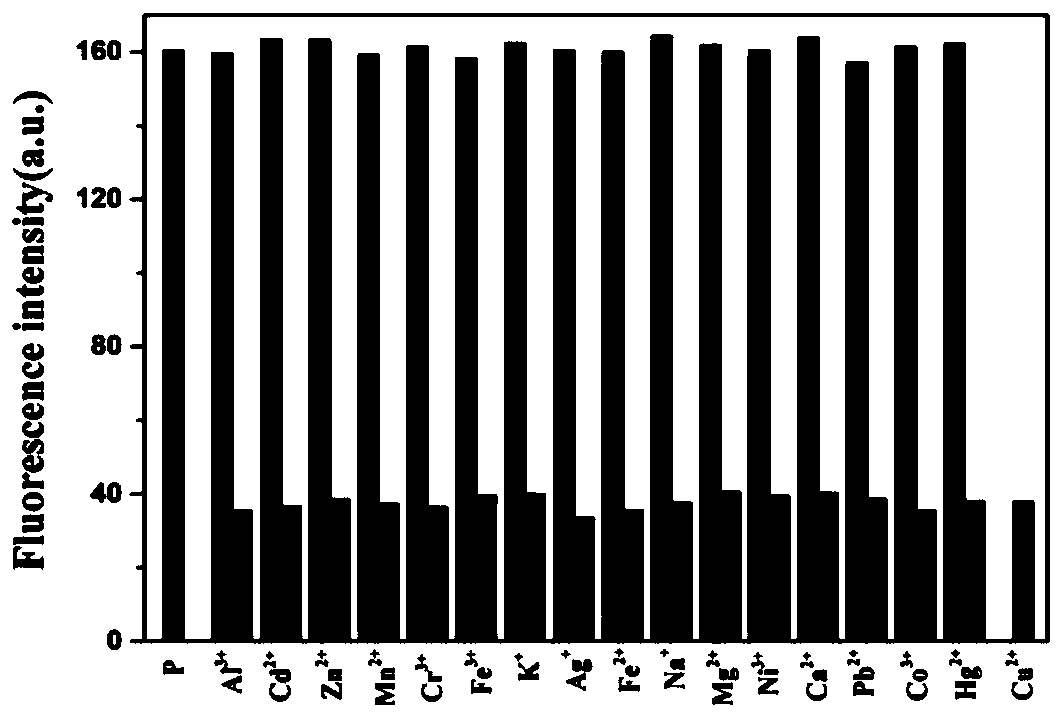

A Peptide Fluorescent Probe Specifically Binding to Copper Ion and Cysteine

ActiveCN110186891BEasy to makeGood biocompatibilityPeptidesFluorescence/phosphorescenceFluoProbesFluorescence

The invention discloses a polypeptide fluorescence probe specifically binding cupric ions with cysteine. The amino acid sequence of the polypeptide is as shown in SEQ ID NO: 1; an N end of the polypeptide is modified with a fluorescent luminescent substance to form the polypeptide fluorescence probe P, the probe is capable of targeting and binding the Cu2+, has good selectivity, low toxicity and low detection limit, is simple to prepare and convenient to detect, and provides an efficient detection method for detecting cupric ions in biological and environmental samples; and the probe P is combined with the Cu2+ to form a P-Cu probe, and the probe can specifically identify Cys, and provide an efficient detection method for the rapid detection of the Cys in living bodies and environmental samples.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com