Method for producing copper-clad aluminum pipe and used production line

A production method, copper-clad aluminum technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as process difficulty, and achieve the effects of reducing load, weight, and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

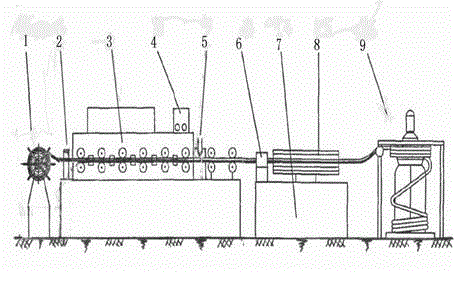

[0024] 2. The cut copper-aluminum composite strip is placed on the tray 1 with the aluminum layer facing up and the copper layer facing down.

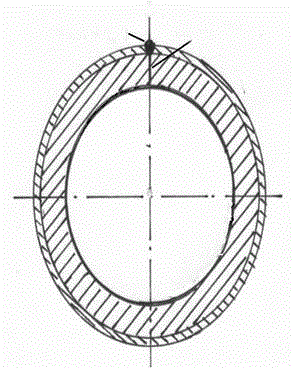

[0025] 3. When the copper-aluminum composite strip passes through the groove cutting device 2, after the two ends of the aluminum layer are cut out of the 45° groove, it enters the tubular forming device 3, so that the copper-aluminum composite strip is formed into a round tube, and is welded by an argon arc welding machine. The welding torch 5 of 4 welds the longitudinal seam of the copper layer of the pipe.

[0026] 4. The tube blank after welding enters the drawing and diameter reducing process. After the large plate 8 of the wire drawing machine 7 pulls the pipe blank through the wire drawing die 6 with a die hole diameter of φ13.1mm, it is wound on the take-up reel of the take-up device 9 .

[0027] The driving power of each device in the entire production line is driven by the wire drawing machine, so that the movement speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com