Solid amine carbon dioxide adsorption material, preparation method and application

A technology of amine carbon dioxide and adsorption materials, which is applied in the field of preparation of solid amine carbon dioxide adsorption materials, can solve the problems of poor dispersion and stability of organic amines in adsorbents, and achieve the effects of low price, low energy consumption and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

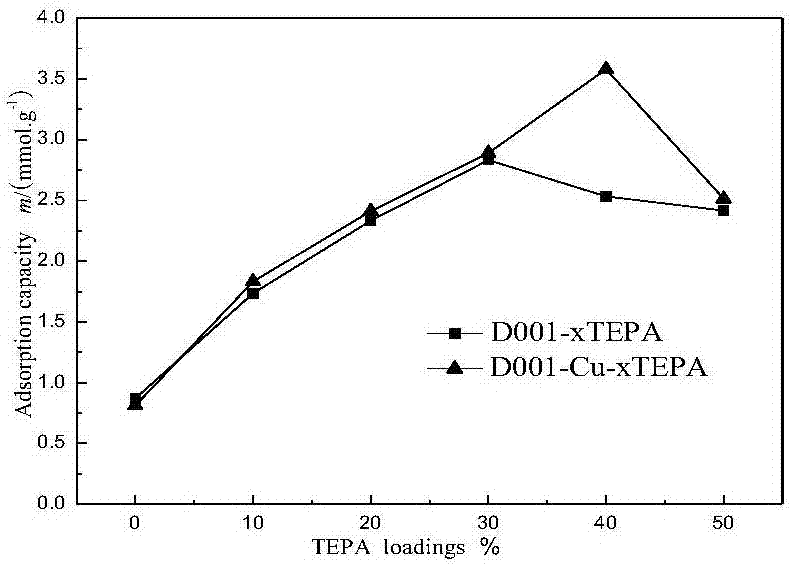

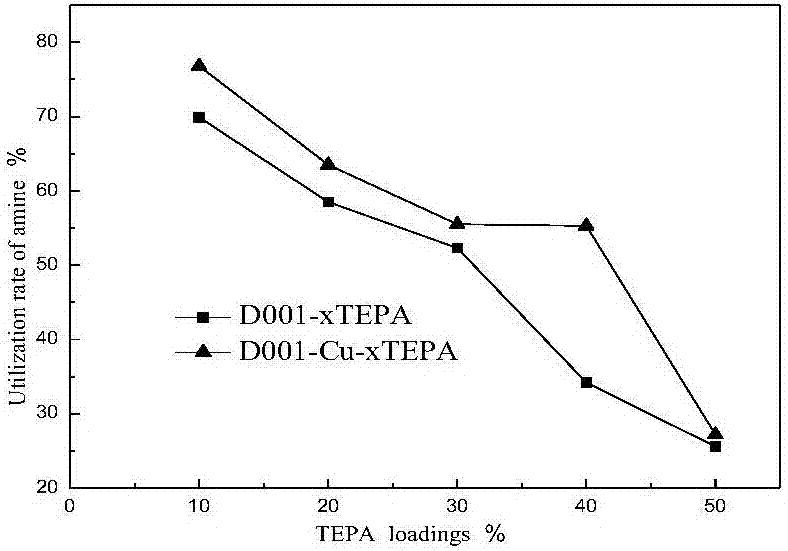

[0029] Weigh 0.1-0.5g TEPA and dissolve it in 30mL of methanol, add 0.5-0.9g D001 and sonicate for 3 hours in an ultrasonic instrument; remove the methanol on a rotary evaporator at 40°C with a vacuum of 5KPa, and dry it in a vacuum at 85°C drying in an oven to obtain a solid amine carbon dioxide adsorption material.

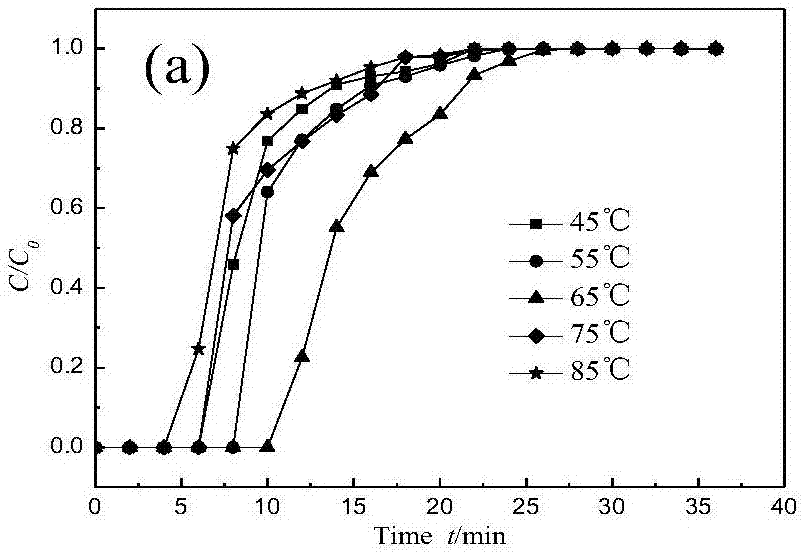

[0030] Using the obtained adsorbent for CO 2 adsorption. Fill the adsorbent in a fixed-bed reactor (a stainless steel tube with a height of 400 mm and an inner diameter of 27 mm), and feed 30 mL / min of high-purity N at 110 °C under normal pressure. 2 Purging for 1h to remove the adsorbed H 2 O and CO 2 . Cool the temperature to the adsorption temperature of 65°C and switch to a certain flow rate of 15% CO 2 / 85%N 2 (volume fraction) mixed gas, start the adsorption experiment. The outlet gas was collected every 2 min and CO was measured by gas chromatograph 2 concentration. When importing and exporting CO 2 When the concentrations are equal, the adsorpt...

Embodiment 2

[0032] Soak D001 in 0.25mol / L copper chloride solution for 12 hours to make Cu 2+Exchange to the resin to obtain D001-Cu; weigh 0.1-0.5g TEPA and dissolve it in 30mL methanol, add 0.5-0.9g D001-Cu and sonicate it in an ultrasonic instrument for 3h; on a rotary evaporator at 40°C, the vacuum degree is 5KPa In the case of removing methanol, drying in a vacuum oven at 85°C, the solid amine carbon dioxide adsorption material was obtained.

[0033] Using the obtained adsorbent for CO 2 adsorption. Fill the adsorbent in a fixed-bed reactor (a stainless steel tube with a height of 400 mm and an inner diameter of 27 mm), and feed 30 mL / min of high-purity N at 110 °C under normal pressure. 2 Purging for 1h to remove the adsorbed H 2 O and CO 2 . Cool the temperature to the adsorption temperature of 65°C and switch to a certain flow rate of 15% CO 2 / 85%N 2 (volume fraction) mixed gas, start the adsorption experiment. The outlet gas was collected every 2 min and CO was measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com