Comprehensive utilization method of reverse flotation products of calcium and magnesium carbonates in mixed copper ores

A technology of calcium magnesium carbonate and mixed copper ore is applied in the field of beneficiation, which can solve the problems of not being used, the beneficiation method cannot recover copper, the problem of resource beneficiation and smelting has not been broken through, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

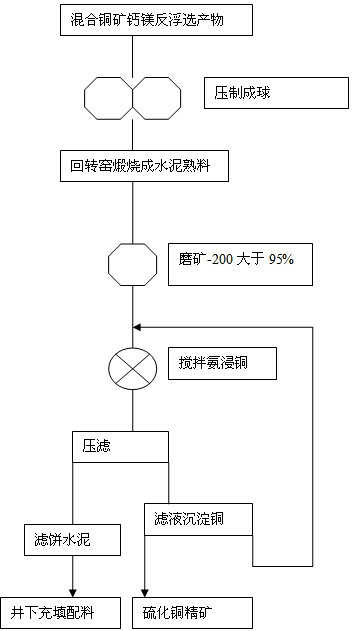

Image

Examples

Embodiment 1

[0023] The calcium-magnesium reverse flotation product of mixed copper ore contains 0.50% copper, mainly bound copper, 25.63% calcium oxide, 2.80% magnesium oxide, 18.56% silicon dioxide, 13.87% aluminum oxide, and 4.88% iron .

[0024] (1) Press the copper-containing calcium-magnesium carbonate product obtained from the reverse flotation of the mixed copper ore into pellets of 12-20mm, send it into the cement rotary kiln, calcinate at 1300°C for 90min, and discharge the rotary pellets Cool to room temperature after kiln.

[0025] (2) Put the calcined pellets obtained from the step (1) into a ball mill, grind the ore at a concentration of 70wt% to -200 mesh greater than 95%, put the grinding slurry into the mixing tank, add the ammonia after copper extraction Solution to pulp concentration 30wt%, add ammonia water and ammonium carbonate according to the ratio of ammonia water: ammonium carbonate=1:1, make NH 3 The concentration was kept at 1mol / L, and stirred and leached for...

Embodiment 2

[0030] The mixed copper ore calcium magnesium reverse flotation product contains 0.65% copper, mainly bound copper, 18.37% calcium oxide, 3.10% magnesium oxide, 22.75% silicon dioxide, 18.66% aluminum oxide and 8.56% iron .

[0031] (1) Press the copper-containing calcium-magnesium carbonate product obtained from the reverse flotation of the mixed copper ore into pellets of 12-20 mm, send it into the cement rotary kiln, calcinate at 1350 ° C for 80 minutes, and discharge the rotary Cool to room temperature after kiln.

[0032] (2) Put the calcined pellets obtained from the step (1) into a ball mill, grind the ore at a concentration of 75wt% to -200 mesh greater than 95%, put the grinding slurry into the mixing tank, and add ammonia after copper extraction Solution to pulp concentration 35wt%, add ammonia water and ammonium carbonate according to the ratio of ammonia water: ammonium carbonate=1:1, make NH 3 The concentration was kept at 1.5mol / L, and stirred and leached for 5...

Embodiment 3

[0037] The calcium-magnesium reverse flotation product of mixed copper ore contains 0.72% copper, mainly bound copper, 20.21% calcium oxide, 2.70% magnesium oxide, 21.87% silicon dioxide, 17.90% aluminum oxide and 9.36% iron .

[0038] (1) Press the copper-containing calcium-magnesium carbonate product obtained from the reverse flotation of the mixed copper ore into pellets of 12-20 mm, send it to the cement rotary kiln, calcinate at 1400 ° C for 60 minutes, and discharge the rotary Cool to room temperature after kiln.

[0039] (2) Put the calcined pellets obtained from step (1) into a ball mill, grind the ore at a concentration of 80wt% to -200 mesh greater than 95%, put the grinding slurry into the mixing tank, add the ammonia after copper extraction Solution to pulp concentration 40wt%, add ammonia water and ammonium carbonate according to the ratio of ammonia water: ammonium carbonate=1:1, make NH 3 The concentration was kept at 2mol / L, and stirred and leached for 30min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com