Product quality prediction method and system for industrial copper foil production

A product quality and prediction method technology, applied in the direction of prediction, neural learning methods, biological neural network models, etc., can solve problems such as the inability to effectively express BDP multi-input-multi-output, data element aggregation, etc., to achieve accurate prediction and realize process The effect of the parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

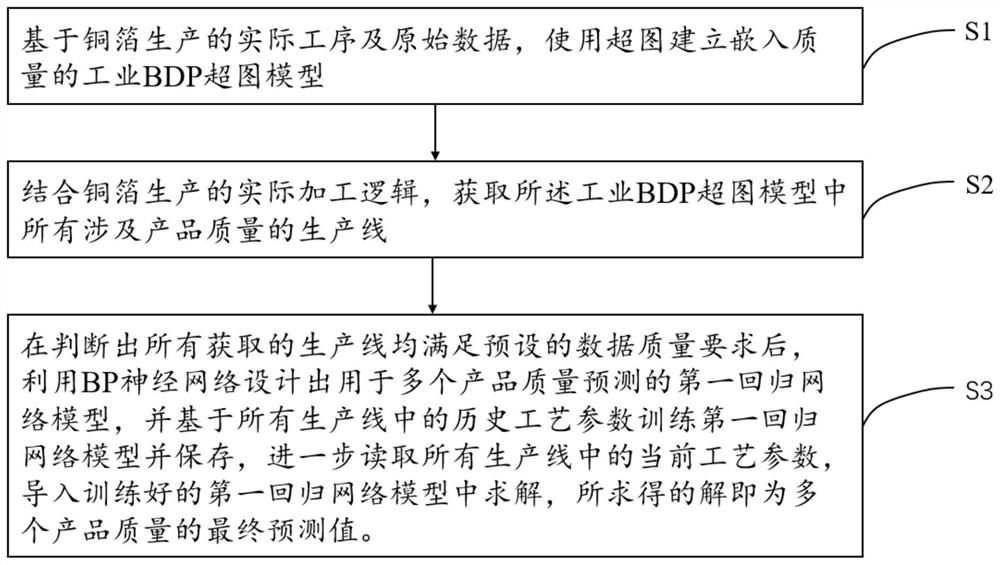

[0038] Such as figure 1 As shown, in the embodiment of the present invention, a kind of product quality prediction method oriented to industrial copper foil production is proposed, comprising the following steps:

[0039] Step S1, based on the actual process and original data of copper foil production, using the hypergraph to establish an industrial BDP hypergraph model with embedded quality;

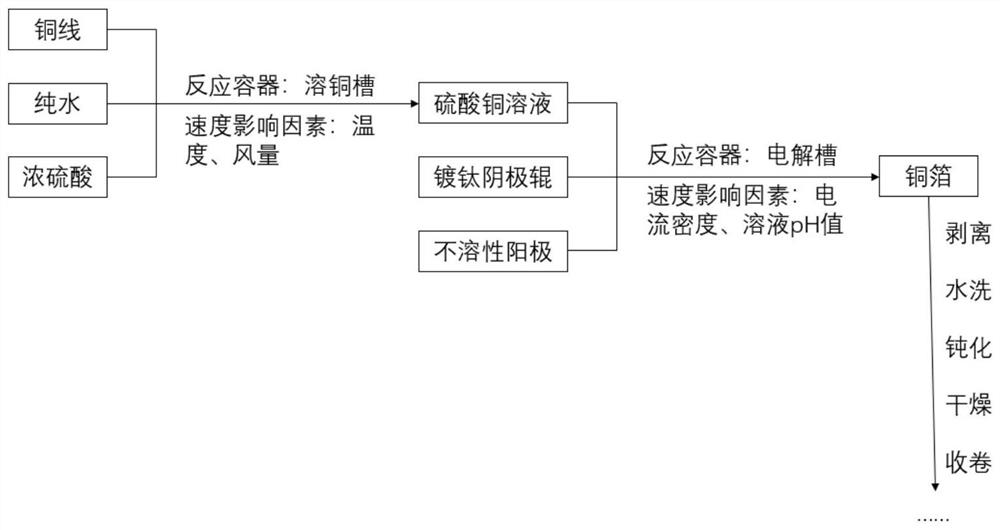

[0040] The specific process is that the copper foil is transported and cut after a series of treatments, so the follow-up process is omitted, and only the actual process of producing molten copper and electrolytic copper foil is focused on, such as figure 2 shown.

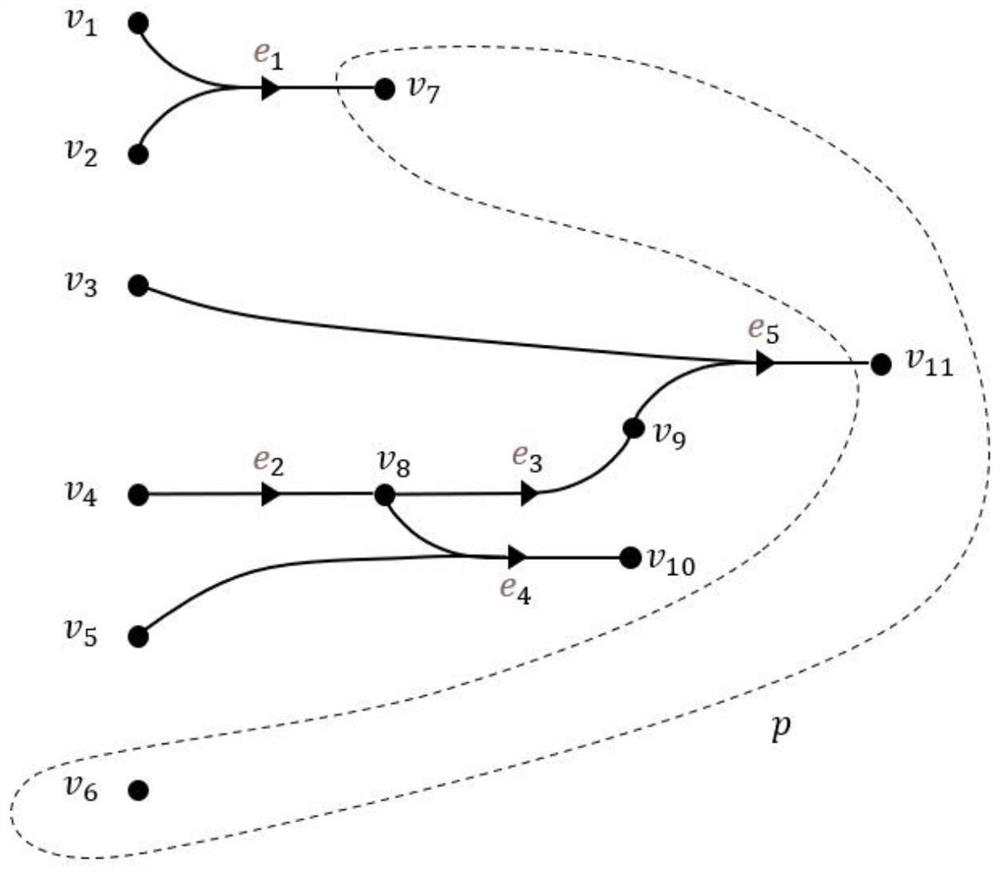

[0041] At this time, there are 6 types of unprocessed raw data collected, denoted as v 1 -v 6 , and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com