Macromolecule bridging flotation method for combined copper disseminated body

A polymer and bridging technology, applied in flotation, solid separation and other directions, can solve the problems of no flotation recovery, complex adsorption characteristics, and small number of copper atoms on the surface, so as to increase the cost of flotation reagents and reduce the cost of flotation reagents. The effect of low cost and less copper ion consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The copper grade of the ore in the combined copper disseminated body is 0.45%, the distribution rate of copper in the combined copper disseminated body is 80%, and the theoretical copper grade in the combined copper disseminated body is 4-6 wt%.

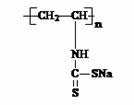

[0029] (1) The ore containing the copper-bound disseminated body is ground to make the monomer dissociation degree of the bound copper disseminated body greater than 80%, put it into the first mixing tank, add water to adjust the pulp concentration to 30wt%, add polyethylene diethyl Sodium thiocarbamate is 30g / t, stirred at a speed of 0.5-1m / s for 4-5min, so that polyethyl dithiocarbamate anion will undergo polyatomic adsorption on the surface of the copper-dipped body.

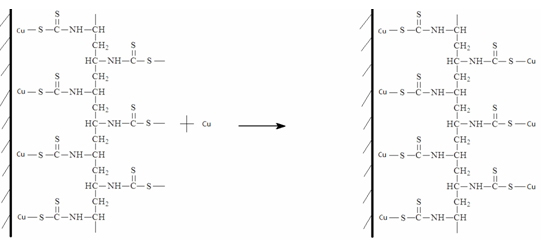

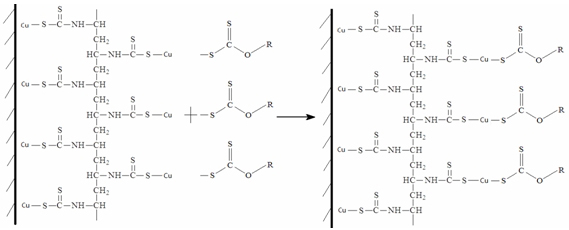

[0030] (2) Put the ore slurry obtained in step (1) into the second mixing tank, add 30g / t copper sulfate, and stir at a speed of 0.5-1m / s for 3-4min, so that the copper ions are deposited on the polyethyl group on the mineral surface. Adsorption on the dithio...

Embodiment 2

[0035] The copper grade of the combined copper disseminated body is 0.50%, the copper distribution rate of the combined copper disseminated body is 60%, the copper distribution rate of the chrysocolla is 30%, and the theoretical copper grade of the combined copper disseminated body is 3-4 wt%.

[0036] (1) The ore containing bound copper disseminated body is ground, so that the monomer dissociation degree of bound copper disseminated body and chrysocolla is greater than 80%, put into the first mixing tank, add water to adjust the pulp concentration to 35wt%, add Sodium polyethyldithiocarbamate 20g / t, stirred at a speed of 0.5~1m / s for 4~5min, so that polyethyldithiocarbamate anions will undergo polyatomic adsorption on the surface of the combined copper disseminated body and chrysocolla .

[0037] (2) Put the ore slurry obtained in step (1) into the second mixing tank, add 20g / t copper sulfate, and stir at a speed of 0.5-1m / s for 3-4min, so that the copper ions are deposited o...

Embodiment 3

[0042]The copper grade of the combined copper disseminated body is 0.40%, the copper distribution rate of the combined copper disseminated body is 50%, the copper distribution rate of the isomorphic combined copper is 40%, and the theoretical copper grade of the combined copper disseminated body is 3-4 wt%.

[0043] (1) The ore containing the copper-bound disseminated body is ground, so that the monomer dissociation degree of the bound copper-dissolved body is greater than 80%, put into the first mixing tank, add water to adjust the pulp concentration to 40wt%, add polyethylene Sodium thiocarbamate 40g / t, stirred at a speed of 0.5-1m / s for 4-5min, so that polyethyl dithiocarbamate anion undergoes polyatomic adsorption on the surface of the bound copper disseminated body.

[0044] (2) Put the ore slurry obtained in step (1) into the second mixing tank, add 40g / t copper sulfate, and stir at a speed of 0.5-1m / s for 3-4min, so that the copper ions are deposited on the polyethyl gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com