A kind of selection method of copper-lead sulfide ore

A sulfide ore, copper-lead technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of copper and lead, and achieve the effect of reducing the slurry potential, high-efficiency separation, and good flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

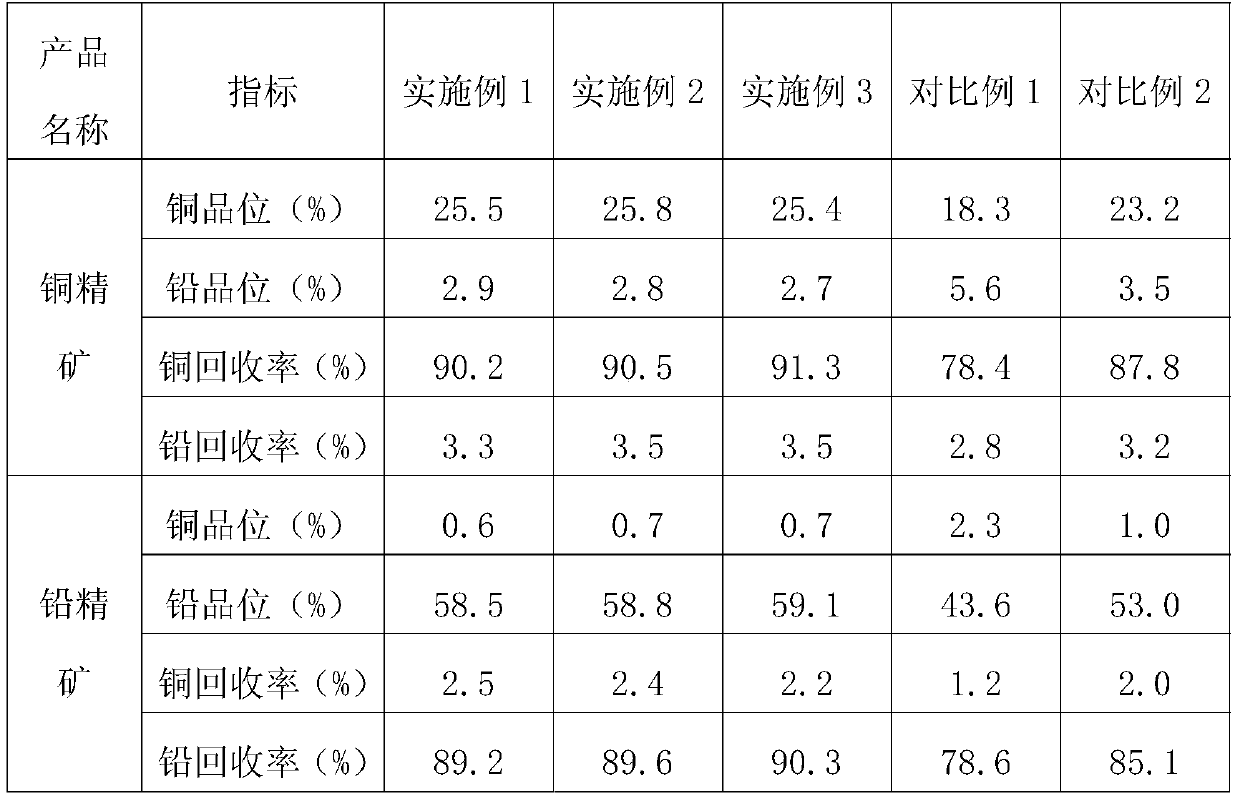

Embodiment 1

[0029] A method for selecting copper-lead sulfide ore, comprising the following steps:

[0030] (1) Raw ore grinding: Finely grind the selected raw ore to obtain an ore slurry with an abrasive grain size of -74 μm, accounting for 76%.

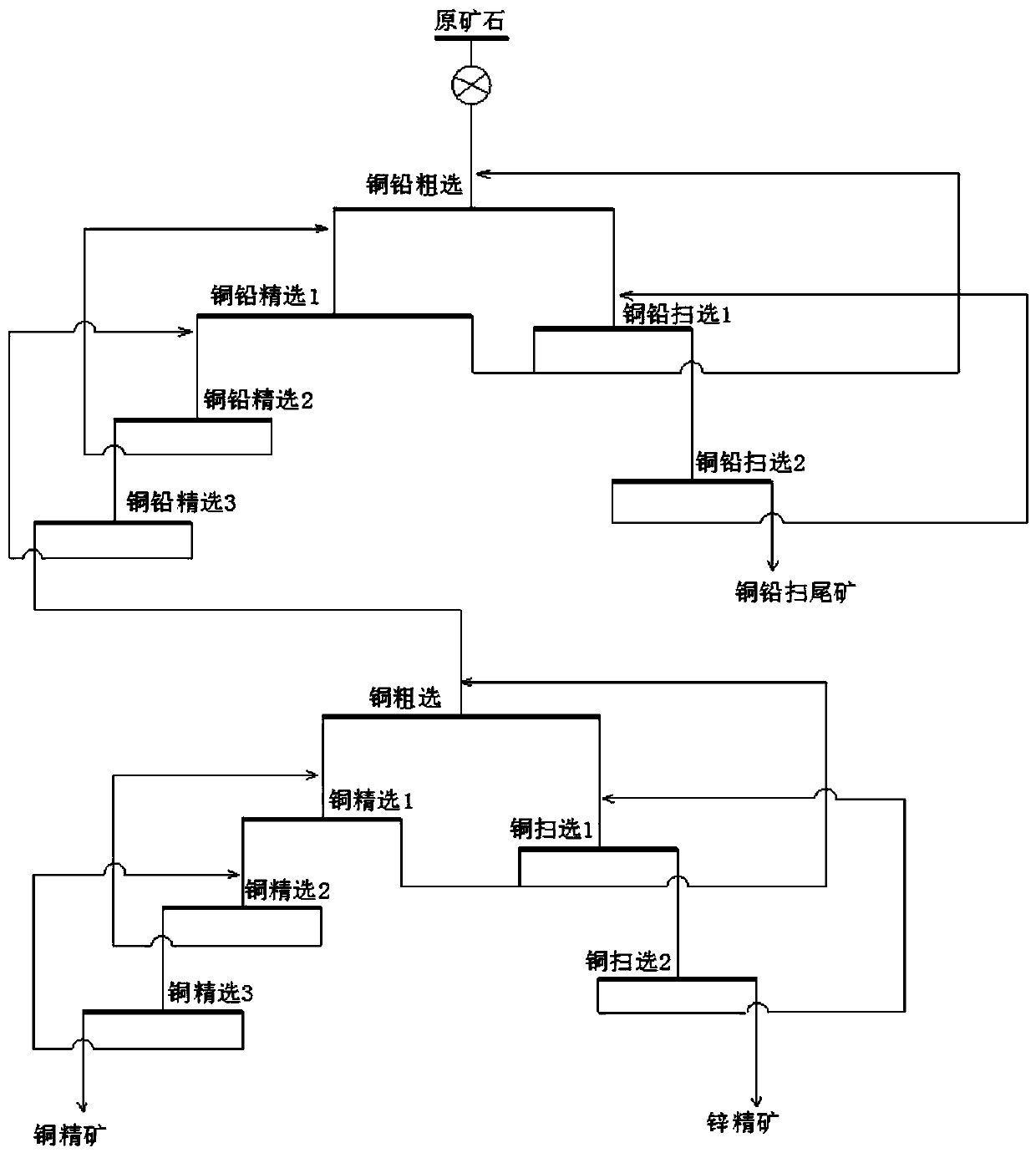

[0031] (2) Copper-lead mixed flotation: the described ore slurry obtained in step (1) is subjected to a rough separation of copper and lead, three times of copper-lead concentration and two times of copper-lead sweeping to obtain copper-lead concentrate and copper-lead tailings . During copper-lead mixed flotation, the mass percent concentration of the pulp is adjusted to 35%, the pH is adjusted to 9, and the copper-lead medium ore produced in the copper-lead mixed flotation process is returned to the previous process in sequence.

[0032] The following reagents are added to the copper and lead roughing process: lime 2000g / t, calcium hypochlorite 600g / t, zinc sulfate 800g / t, sodium sulfite 400g / t, sodium sulfide 300g / t, dimethyl dicarbonate 20...

Embodiment 2

[0040] A method for selecting copper-lead sulfide ore, comprising the following steps:

[0041] (1) Raw ore grinding: Finely grind the selected raw ore to obtain an ore slurry with an abrasive particle size of -74 μm, accounting for 80%.

[0042] (2) Copper-lead mixed flotation: the described ore slurry obtained in step (1) is subjected to a rough separation of copper and lead, three times of copper-lead concentration and two times of copper-lead sweeping to obtain copper-lead concentrate and copper-lead tailings . During copper-lead mixed flotation, the mass percentage concentration of the pulp is adjusted to 45%, the pH is adjusted to 12, and the copper-lead medium ore produced in the copper-lead mixed flotation process is returned to the previous step in sequence.

[0043] The following reagents are added to the copper and lead roughing process: lime 2400g / t, calcium hypochlorite 800g / t, zinc sulfate 1000g / t, sodium sulfite 600g / t, sodium sulfide 600g / t, dimethyl dicarbona...

Embodiment 3

[0051] A method for selecting copper-lead sulfide ore, comprising the following steps:

[0052] (1) Raw ore grinding: Finely grind the selected raw ore to obtain an ore slurry with an abrasive grain size of -74 μm, accounting for 78%.

[0053] (2) Copper-lead mixed flotation: the described ore slurry obtained in step (1) is subjected to a rough separation of copper and lead, three times of copper-lead concentration and two times of copper-lead sweeping to obtain copper-lead concentrate and copper-lead tailings . During copper-lead mixed flotation, the mass percentage concentration of the pulp is adjusted to 40%, the pH is adjusted to 11, and the copper-lead middlings produced in the copper-lead mixed flotation process are returned to the previous process in sequence.

[0054] The following reagents are added to the copper and lead roughing process: lime 2200g / t, calcium hypochlorite 700g / t, zinc sulfate 900g / t, sodium sulfite 500g / t, sodium sulfide 450g / t, dimethyl dicarbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com