High-speed end sealing wire structure

A wiring structure and end sealing technology, applied in the direction of connections, current collectors, electrical components, etc., can solve the problems of power line breakage, leakage, and easy cracking of the wire insulation layer, and achieve the effect of simple structure and solving the problem of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

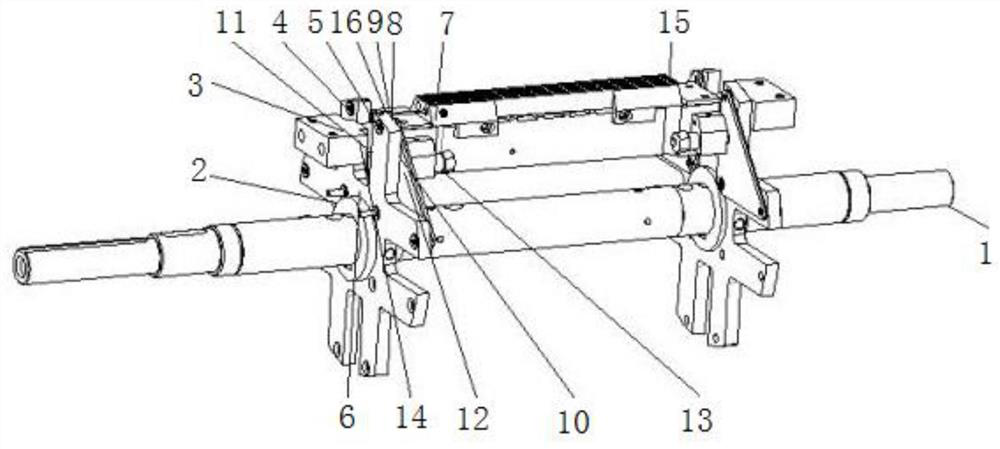

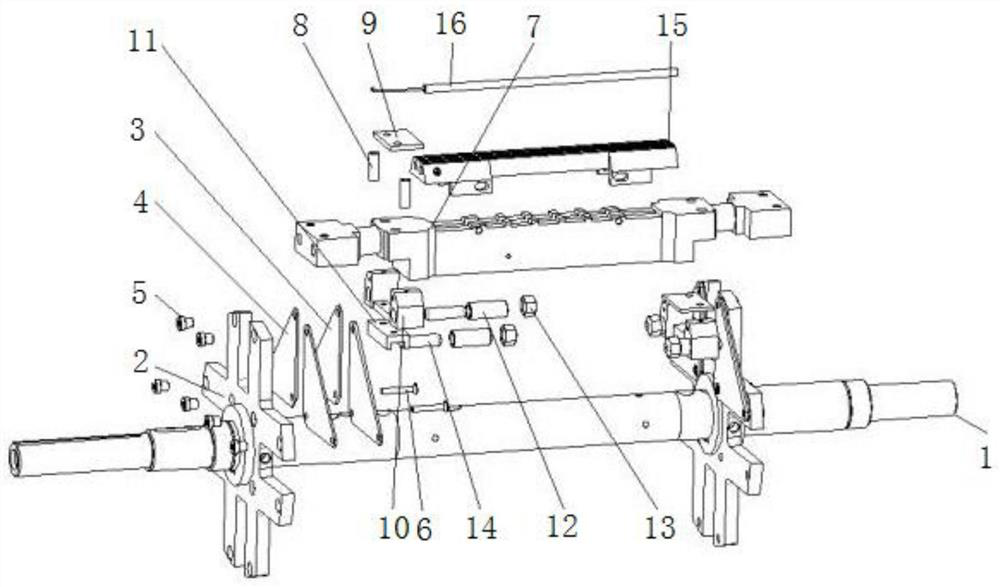

[0014] The main structure of the high-speed terminal sealing line structure involved in this embodiment is as follows: figure 1As shown, the main structure includes end seal shaft 1, indexing plate 2, copper plate 3, insulating plate 4, insulating flange 5, copper screw 6, bracket 7, insulating sleeve 8, insulating backing plate 9, copper block 10, insulating Pad block 11, hollow copper stud 12, copper nut 13, carbon brush 14, sealer 15 and heating tube 16; the two ends of the end seal shaft 1 of the inner hollow structure are respectively provided with an indexing plate 2, and the indexing plate 2 is fixed on the end seal shaft 1 by means of flat keys and tight nails, a copper plate 3 is arranged on the inner side of the index plate 2, an insulating plate 4 is arranged between the index plate 2 and the copper plate 3, and the index plate 2, copper plate 3 and insulation The plate 4 is connected as a whole through the insulating flange 5 with a central through hole. The insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com