Fixing method for ceramic tile

A fixing method and technology of ceramic tiles, which are applied to roofs, roofs, buildings, etc. that use tiles/slate tiles, can solve the problem of unsatisfactory fixing of ceramic tiles and roof bases, inconvenient fixing of ceramic tiles and roof bases, and impact on Residential safety use and other issues, to achieve the effect of reducing engineering costs, fast and easy construction, and preventing tiles from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

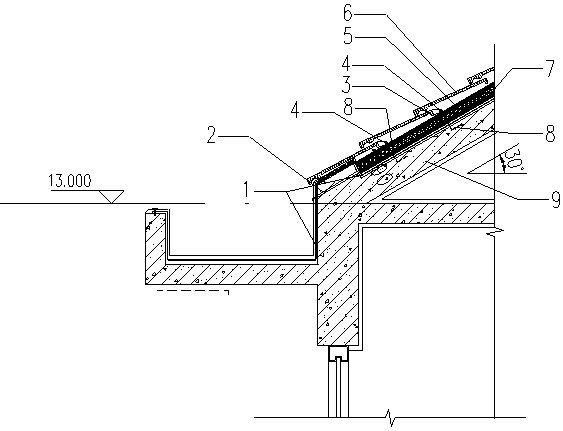

Image

Examples

Embodiment 1

[0031] Zhongji. Putian Courtyard Phase I project is located in the east of Neishancheng Road, north of Jinhu Road, and west of Inner Sea in Mazu City Economic Development Zone, Xiuyu District, Putian City. The project is close to the sea and is eroded by sea wind all the year round. The land is made of sand, including an underground garage, 2 high-rise buildings (30 floors), 133 villas, a clubhouse, some shops and supporting rooms, with a total area of about 133080m 2 ; of which villas (building area 60,000 m 2 ) has one basement floor and four floors above the ground. It is a reinforced concrete frame structure, and its roofs are all sloping roofs (ceramic flat tiles), and the sloping roofs have an inclination angle of 30°.

[0032] The ceramic tile fixing method of the present invention is used in this project, and its construction process is: pre-embedded steel bars in the structural layer → waterproof layer → heat preservation layer → leveling layer → lying tile layer → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com