Coke oven baking platform fixing method

A fixed method and platform technology, applied in coke ovens, preheating coke ovens, heating of coke ovens, etc., can solve problems such as safety risks, poor reusability of oven platforms, and damage to H-shaped steel columns of coke ovens. To achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

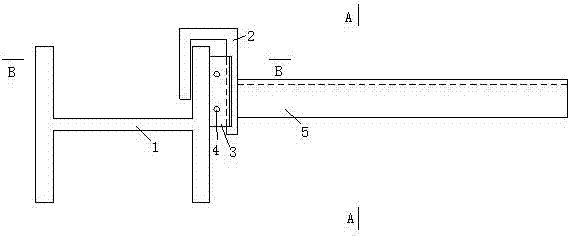

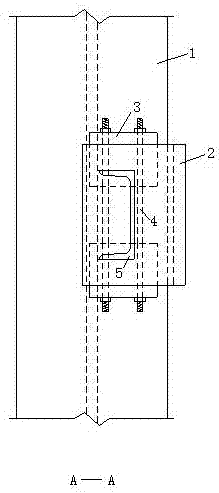

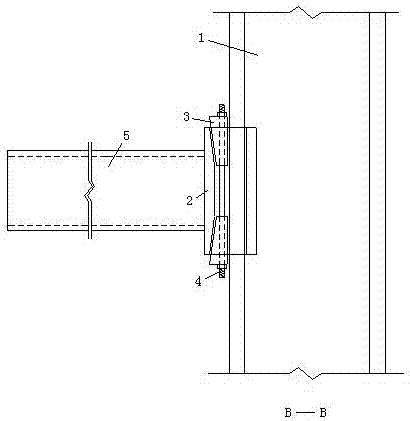

[0033] The method for fixing the coke oven oven platform of the present invention comprises the following steps:

[0034] a. Make "U" shaped card

[0035] see now Figure 4-6 , Figure 4 It is a schematic structural diagram of a "U"-shaped card according to an embodiment of the present invention, Figure 5 for Figure 4 C-C sectional view in, Figure 6 for Figure 4 D-D section view in . As shown in the figure, the "U"-shaped card 2 is designed and processed according to the specifications of the conventional coke oven H-shaped steel column 1. The "U"-shaped card is a steel card, and the two ends of the U-shape are irregular. The long end 22 of the long end 22 is longer than the U-shaped short end 21, and the inner side 23 of the long end 22 is provided with a U-shaped long end slope 24 with a certain slope;

[0036] Provide two first sliders 31 and second sliders 32 of the same size and shape, the cross-sections of the first slider 31 and the second slider 32 are trape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com