Beneficiation method of mixed copper ore having low oxidation rate and high binding rate

A technology of low oxidation rate and beneficiation method, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem that the low oxidation rate has not been broken through, and cannot simultaneously solve the recycling and utilization of low oxidation rate oxygen-sulfur mixed copper ore, etc. problem, to achieve the effect of saving sulfuric acid, high cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

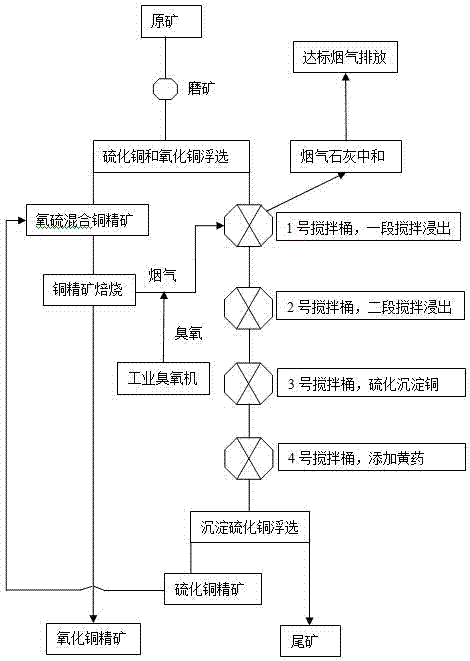

Image

Examples

Embodiment 1

[0029] Raw materials: mixed copper ore containing 1.2% copper, 30% oxidation rate, 20% bonding rate, and less than 4% calcium oxide and magnesium content.

[0030] (1) Grinding until 80% of the copper sulfide minerals and free copper oxide minerals are dissociated, add 500g of sodium sulfide to sulfide the free copper oxide minerals per ton of dry mixed copper ore, and add 500g of butyl xanthate As a collector for copper sulfide minerals and free copper oxide minerals after sulfidation, 30g of frother terpineol oil is added to control flotation foam, and oxygen-sulfur mixed copper concentrate is obtained by flotation, leaving some difficult flotation free copper concentrates. Copper oxide and bound copper tailings.

[0031] (2) Roast and desulfurize the oxygen-sulfur mixed copper concentrate to obtain the copper oxide concentrate as the final copper concentrate; the roasting flue gas contains sulfur dioxide gas, and the sulfur dioxide gas produced by the industrial ozone machi...

Embodiment 2

[0036] Raw materials: mixed copper ore with 0.8% copper, 26% oxidation rate, 18% bonding rate, and less than 4% calcium oxide and magnesium content.

[0037] (1) Grinding until 80% of the copper sulfide minerals and free copper oxide minerals are dissociated, add 400g of sodium sulfide to sulfide the free copper oxide minerals per ton of mixed copper ore, and add 400g of isoamyl xanthate As a collector for copper sulfide minerals and free copper oxide minerals after sulfidation, add 40 g of foaming agent No. 2 oil to control flotation foam, and obtain oxygen-sulfur mixed copper concentrate by flotation, leaving some difficult flotation free copper concentrates. Copper oxide and bound copper tailings.

[0038] (2) Roasting and desulfurizing the oxygen-sulfur mixed copper concentrate obtained in step (1) to obtain the copper oxide concentrate as the final copper concentrate; the roasting flue gas contains sulfur dioxide gas, and the flue gas produced by the industrial ozone mach...

Embodiment 3

[0043] Mixed copper ore containing 0.5% copper, 20% oxidation rate, 15% binding rate, and less than 4% calcium oxide and magnesium content.

[0044] (1) Grinding until 80% of the copper sulfide minerals and free copper oxide minerals are dissociated, add 300g of sodium sulfide to sulfide the free copper oxide minerals per ton of mixed copper ore, and add 300g of butyl xanthate as Collector for copper sulfide minerals and free copper oxide minerals after sulfidation, add foaming agent terpineol oil 40g to control flotation foam, flotation to obtain oxygen-sulfur mixed copper concentrate, leave some difficult flotation free oxidation Copper and copper-bound tailings.

[0045] (2) Roasting and desulfurizing the oxygen-sulfur mixed copper concentrate obtained in step (1) to obtain the copper oxide concentrate as the final copper concentrate; the roasting flue gas contains sulfur dioxide gas, and the flue gas produced by the industrial ozone machine is introduced into the flue gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com