Furnace-through fixture for reflow soldering

A reflow soldering and furnace passing technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of not obviously increasing the product scrap rate, high cost and manpower, and energy consumption, so as to reduce virtual soldering and open pins The effect of low risk, convenient production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the structures in the drawings are only schematic rather than limiting, so that those skilled in the art can best understand the principles of the present invention, and they are not necessarily drawn to scale.

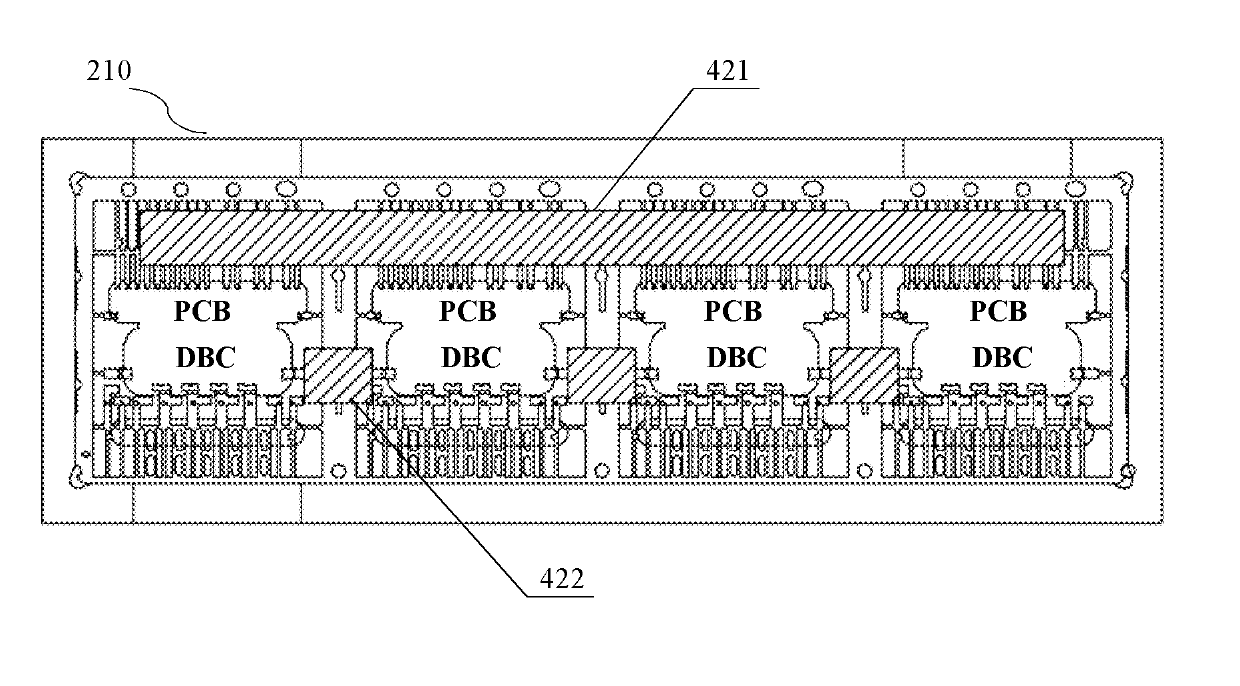

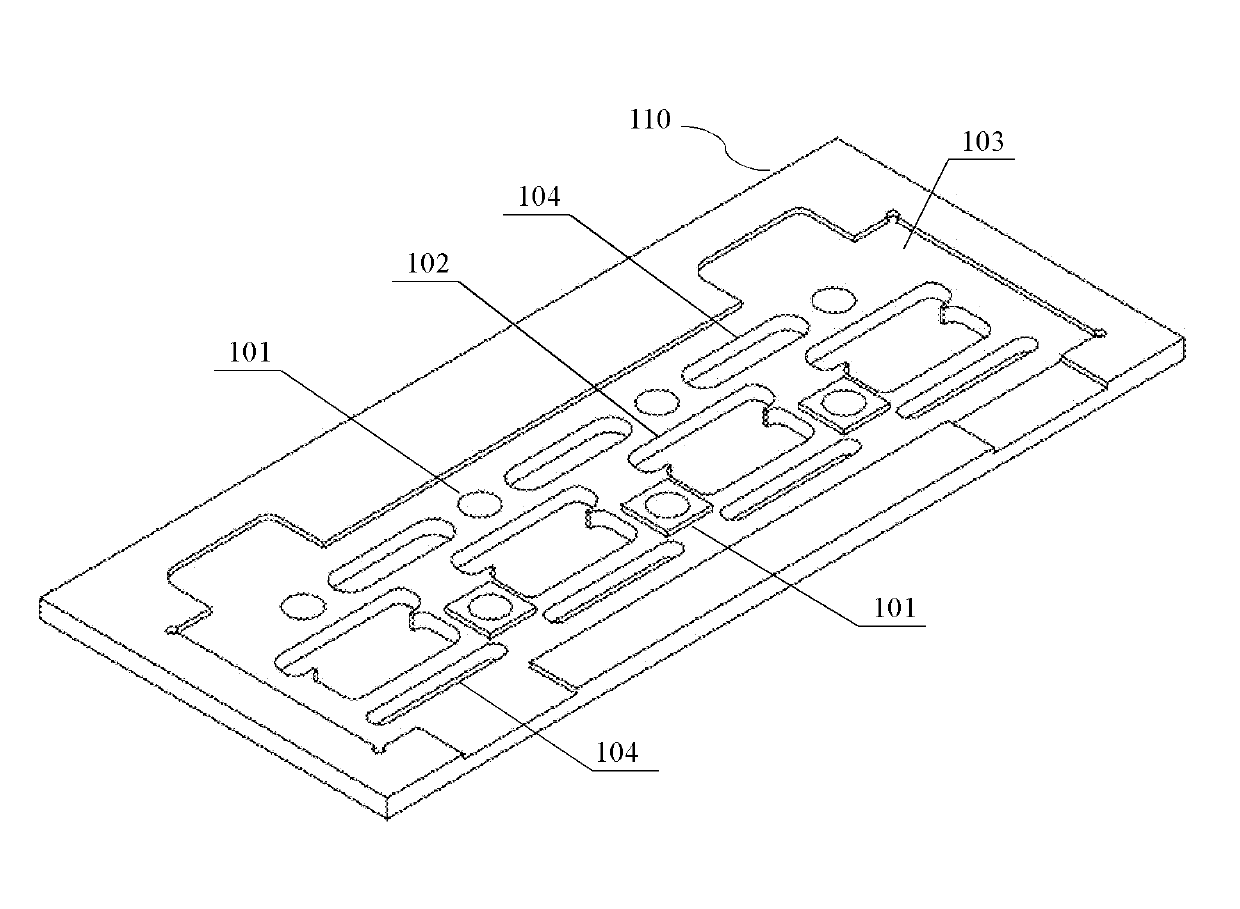

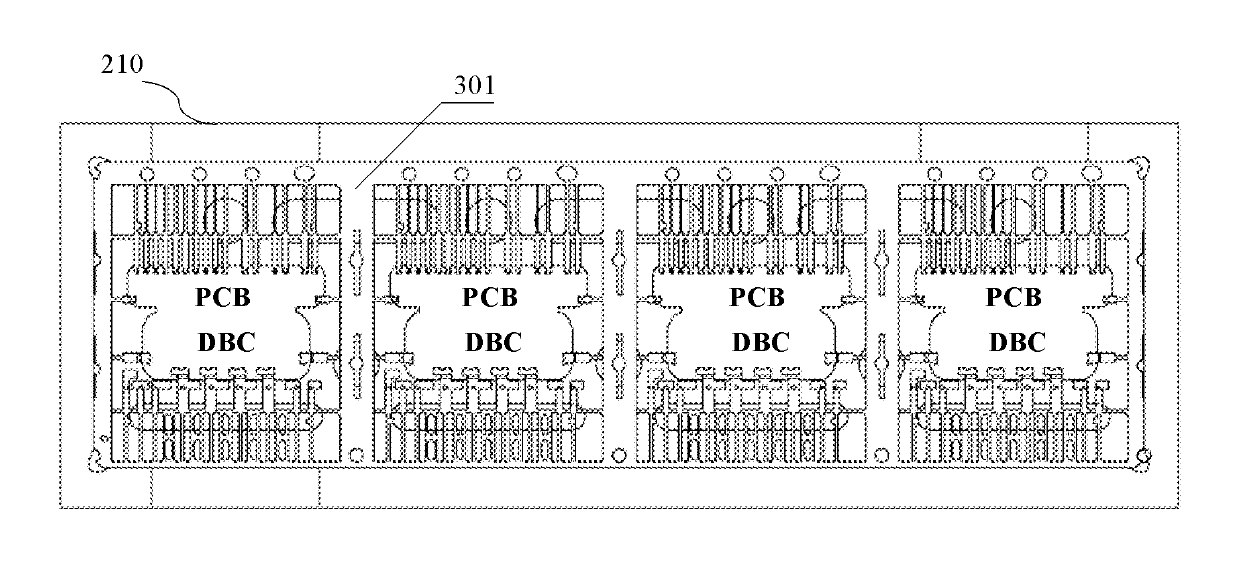

[0026] figure 1 It is a perspective view of a carrier plate of a refractory jig according to an embodiment of the present invention. The reflow fixture provided by the present invention is mainly used to carry the printed circuit board (PCB), copper clad substrate (DBC) and lead frame array required for the manufacture of devices such as intelligent power modules in the reflow soldering process, which mainly includes The carrier plate and the magnetic cover are two parts, in the figure 1 A schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com