Copper wire drawing annealing liquid and using method thereof

An annealing liquid, copper wire drawing technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of hidden quality, cumbersome on-site use, poor control of the ratio, etc., achieve strong antibacterial properties, not easy to make mistakes, and easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

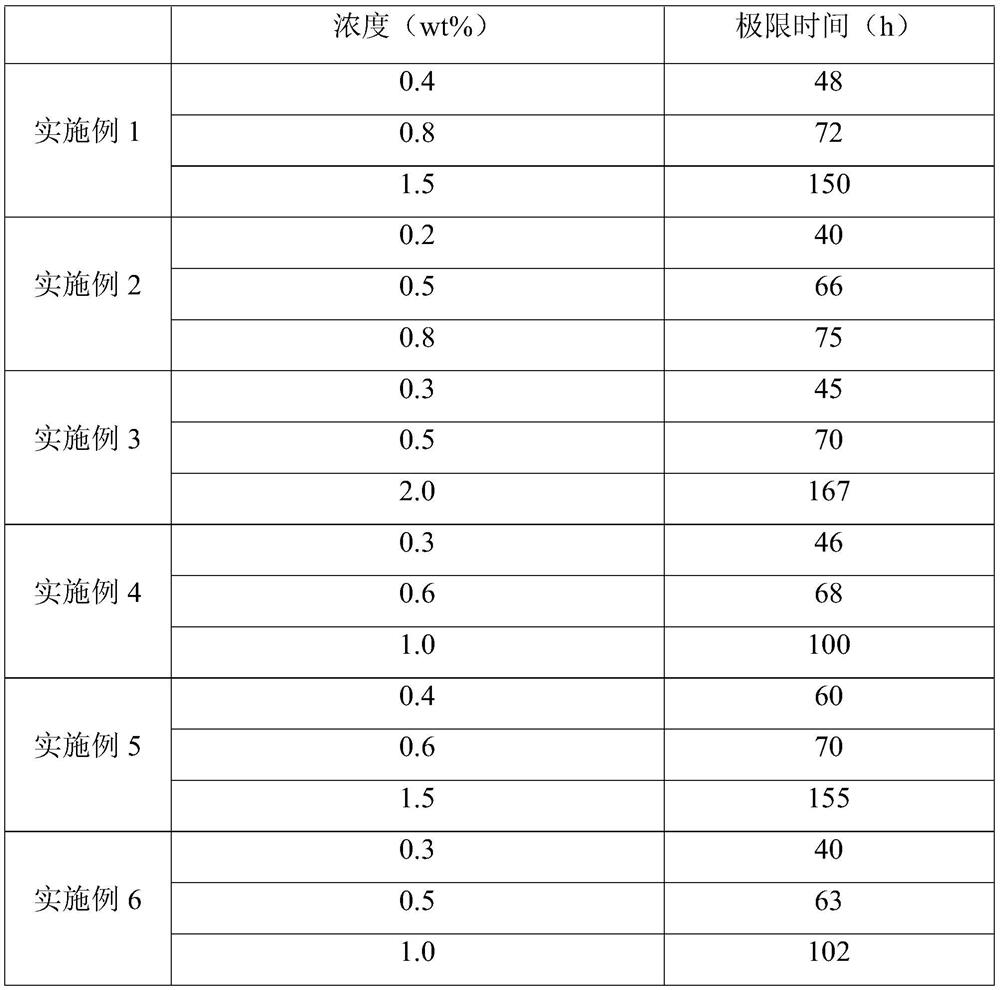

Embodiment 1

[0045] The total weight of the copper wire drawing annealing liquid in this embodiment is 100 parts, including the following components by weight: 40 parts of copper antioxidant, 5 parts of solubilizer, 3 parts of boric acid, 10 parts of organic alcohol amine, 5 parts of rust inhibitor, 5 parts of self-emulsifying ester, 0.01 part of defoamer, 5 parts of bactericide, and the balance of water.

[0046] The copper antioxidant is benzotriazole T706.

[0047] The solubilizer is neodecanoic acid.

[0048] The organic alcohol amine is triethanolamine.

[0049] The rust inhibitor is sebacic acid.

[0050] Self-emulsifying esters are trimer acid self-emulsifying esters.

[0051] The defoamer is Dow Corning 1247.

[0052] The fungicide is fungicide BK.

[0053] Dilute copper wire drawing annealing solution with water to the following concentration:

[0054] For copper wire antirust within 1 month, the concentration of annealing solution for copper wire drawing is 0.4%;

[0055] ...

Embodiment 2

[0058] The total weight of the copper wire drawing annealing liquid in this embodiment is 100 parts, including the following components by weight: 42 parts of copper antioxidant, 4 parts of solubilizer, 5 parts of boric acid, 6 parts of organic alcohol amine, 10 parts of rust inhibitor, 20 parts of self-emulsifying ester, 0.05 parts of defoamer, 6 parts of fungicide, and the balance of water.

[0059] Copper antioxidant is tolyltriazole T706A.

[0060] The solubilizer may be neodecanoic acid.

[0061] The organic alcohol amine is monoethanolamine.

[0062] The rust inhibitor is DDDA dodecanedioic acid.

[0063] Self-emulsifying esters are trimer acid self-emulsifying esters.

[0064] The defoamer is Dow Corning 1267.

[0065] The fungicide is fungicide BK.

[0066] Dilute copper wire drawing annealing solution with water to the following concentration:

[0067] For copper wire antirust within 1 month, the concentration of annealing solution for copper wire drawing is 0.2%;...

Embodiment 3

[0071] The total weight of the copper wire drawing annealing solution in this embodiment is 100 parts, including the following components by weight: 50 parts of copper antioxidant, 3.5 parts of solubilizer, 2 parts of boric acid, 7 parts of organic alcohol amine, 6 parts of rust inhibitor, 15 parts of self-emulsifying ester, 0.07 parts of defoamer, 10 parts of fungicide, and the balance of water.

[0072] The copper antioxidant is benzotriazole T706.

[0073] The solubilizing agent may be an isomeric acid of capric acid.

[0074] The organic alcohol amine is diethanolamine.

[0075] The rust inhibitor can be one of C10-C12 dibasic acids.

[0076] Self-emulsifying esters are trimer acid self-emulsifying esters.

[0077] The defoamer is Meng Qingxin's MS575.

[0078] The biocide is the biocide MBM.

[0079] Dilute copper wire drawing annealing solution with water to the following concentration:

[0080] For copper wire antirust within 1 month, the concentration of annealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com