A method of improving brazing welding strength

A welding strength and brazing technology, which is applied in the field of improving brazing welding strength, can solve the problems that the adhesion effect of the welding surface is greatly affected, the brazing material cannot fill the gap of the joint, and the cost of manufacturing and inspection is increased, so as to improve the welding production. Efficiency and quality stability, controllable management, improved wetting and spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 The welding method of welding 1Cr18Ni9Ti and ceramics

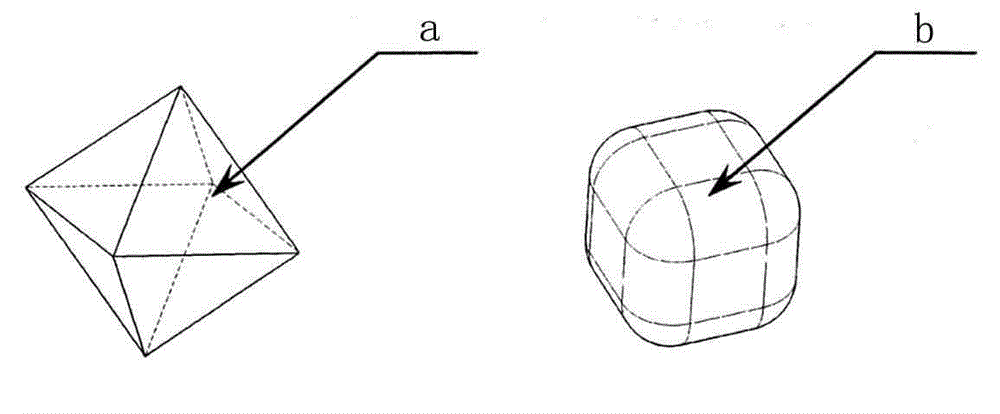

[0015] 1) Preparation of ceramic particles attached to the brazing metal nanopowder used: this example selects as figure 1 For the ceramic particles in the shape shown in b, the particle size of the selected ceramic particles is about 0.8mm, and the nickel-based solder is selected. The operation is as follows: carboxyl groups (-COOH) are introduced on the ceramic surface, which can chemically adsorb Ni 2+ , Ni 2+ After being reduced by the reducing agent, a catalytic active center is formed on the surface of the ceramic substrate, thereby initiating the chemical deposition process, and uniformly dispersed nano-nickel particles are formed on the surface of the ceramic substrate.

[0016] figure 1 Middle b is a ceramic particle with more rounded corners, which is mainly used for the treatment of the surface of the welded body where the interaction between the solder and the base metal is weak or a sma...

Embodiment 2

[0020] Embodiment 2 The welding method of welding 1Cr18Ni9Ti and 0Cr18Ni11Ti

[0021] 1) Preparation of ceramic particles attached to the brazing metal nanopowder used: this example selects as figure 1 For the ceramic particles in the shape shown in a, the particle size of the selected ceramic particles is about 1.5 mm, and the nickel-based solder is selected. The operation is as follows: carboxyl groups (-COOH) are introduced on the ceramic surface, which can chemically adsorb Ni 2+ , Ni 2+ After being reduced by the reducing agent, a catalytic active center is formed on the surface of the ceramic substrate, thereby initiating the chemical deposition process, and uniformly dispersed nano-nickel particles are formed on the surface of the ceramic substrate.

[0022] Such as figure 1 as shown, figure 1 Middle a is a ceramic particle with more edges, which is mainly used for the treatment of the surface of the welded body that has a strong interaction between the brazing fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com