Oxygen partial pressure controlled sintering method for preparing manganese zinc ferrite from secondary materials

A technology of manganese-zinc ferrite and sintering method, applied in the field of magnetic materials, can solve problems such as disadvantages, reduce the cost of manganese-zinc ferrite materials and preparation costs, achieve increased concentration, avoid discontinuous grain growth, save energy The effect of nitrogen dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

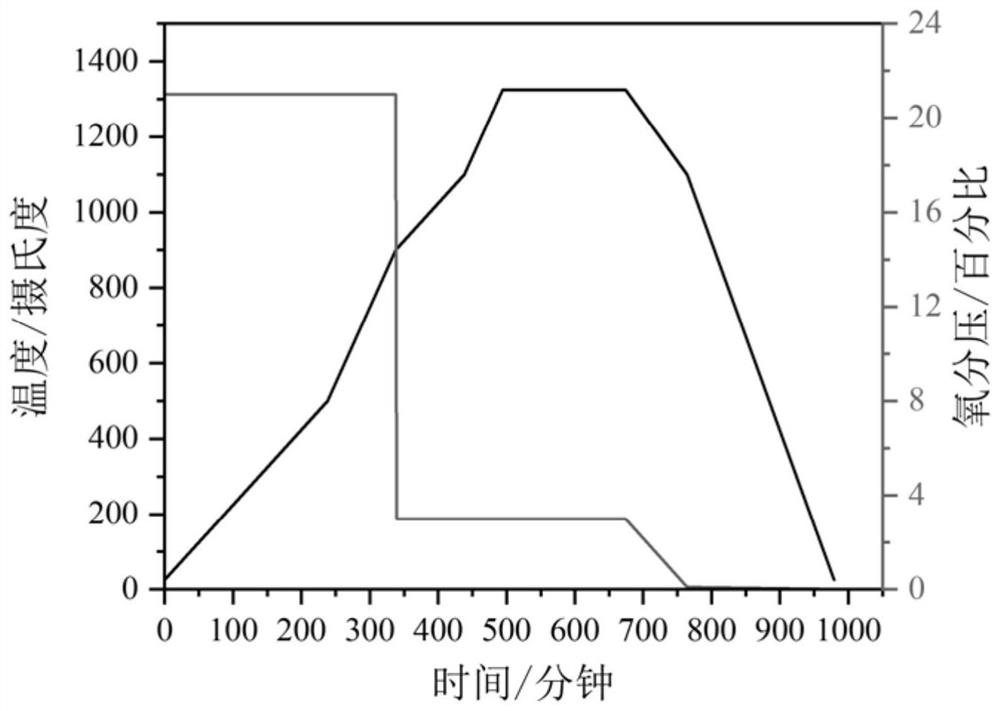

Embodiment 1

[0025] Using manganese zinc ferrite secondary material powder as raw material, the samples were prepared according to the technological process of ball milling→drying→granulation→forming→sintering, and the sintering was carried out in a high-temperature atmosphere tube furnace. The sample is heated in the air during the heating process from room temperature to 900°C. When the temperature rises to 900°C, the sintering oxygen partial pressure is controlled by vacuum pumping and feeding high-purity nitrogen (the vacuum degree required for sintering oxygen partial pressure is based on the required sintering oxygen partial pressure using the gas partial pressure. law Calculated, where x 1 is the sintering oxygen partial pressure described in the present invention, P 1 is the partial pressure of oxygen in the mixed gas, P 总 is the total pressure of the mixed gas), first use the vacuum pump to evacuate to a certain degree of vacuum, and then introduce high-purity nitrogen until t...

Embodiment 2

[0027] Using manganese zinc ferrite secondary material powder as raw material, the samples were prepared according to the technological process of ball milling→drying→granulation→forming→sintering, and the sintering was carried out in a high-temperature atmosphere tube furnace. The sample is heated in the air during the heating process from room temperature to 900°C. When the temperature rises to 900°C, start to control the sintering oxygen partial pressure by vacuuming the vacuum pump and feeding high-purity nitrogen gas. First, use the vacuum pump to pump to a certain degree of vacuum, and then feed high-purity nitrogen gas to the gas pressure of the sintering chamber. After the pressure is 0.1MPa (the outlet pressure of the gas pressure reducing valve is 0.015MPa when high-purity nitrogen is introduced), stop the introduction of high-purity nitrogen to reduce the partial pressure of oxygen to 4%, heat up to 1325°C for 3 hours, and at the same time, the oxygen The partial pr...

Embodiment 3

[0029] Using manganese zinc ferrite secondary material powder as raw material, the samples were prepared according to the technological process of ball milling→drying→granulation→forming→sintering, and the sintering was carried out in a high-temperature atmosphere tube furnace. The sample is heated in the air during the heating process from room temperature to 900°C. When the temperature rises to 900°C, start to control the sintering oxygen partial pressure by vacuuming the vacuum pump and feeding high-purity nitrogen gas. First, use the vacuum pump to pump to a certain degree of vacuum, and then feed high-purity nitrogen gas to the gas pressure of the sintering chamber. After the pressure is 0.1MPa (the outlet pressure of the gas pressure reducing valve is 0.015MPa when high-purity nitrogen is introduced), stop the introduction of high-purity nitrogen to reduce the partial pressure of oxygen to 3%, raise the temperature to 1325 ° C for 3 hours, and at the same time, the oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com