Power battery cover plate

A technology of power battery and cover plate, which is applied in the direction of battery cover/end cover, battery pack parts, battery box/coating, etc., which can solve the problems of heavy weight of negative pole, influence on electrical performance, poor stability, etc., and prolong service life , simplify the connection structure, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

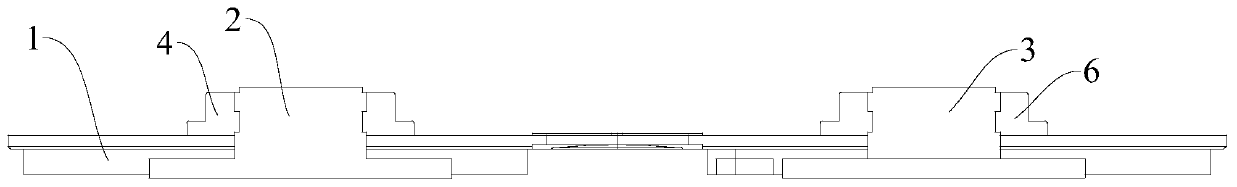

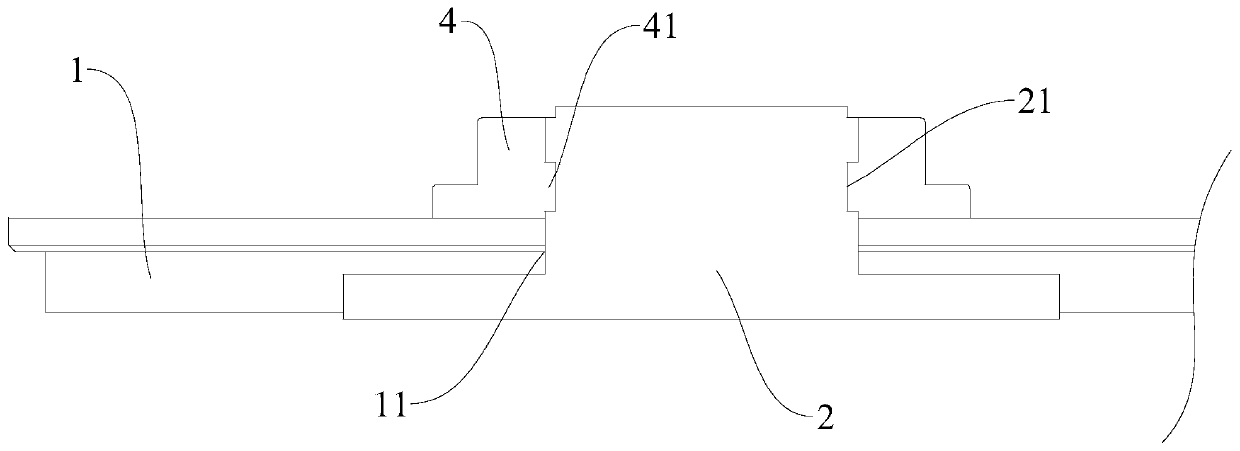

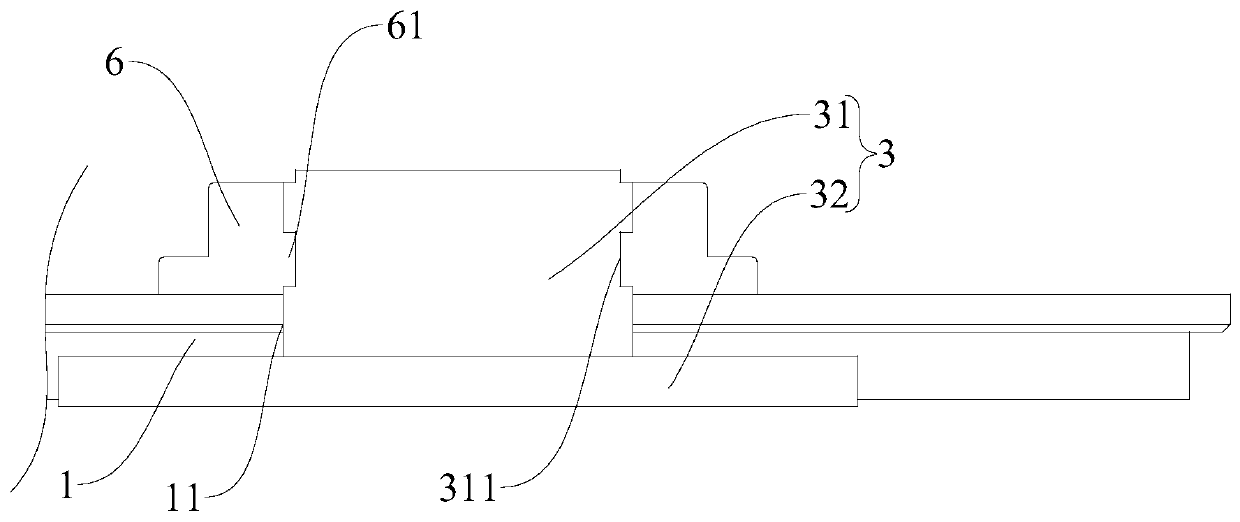

[0060] Refer below Figure 1-Figure 3 A power battery cover plate according to a specific embodiment of the present invention is described.

[0061] like Figure 1-Figure 3 As shown, the power battery cover plate of this embodiment includes a top cover 1, a positive pole 2 and a negative pole 3, the top cover 1 is provided with two through holes 11, and the positive pole 2 and the negative pole 3 are respectively installed in the two through holes. Inside hole 11. The positive pole 2 is an aluminum pole, the negative pole 3 includes an aluminum part 31 and a copper part 32 , the copper part 32 fits on the big end of the through hole 11 , and the aluminum part 31 fits on the small end of the through hole 11 .

[0062] The positive pole 2 is connected to the top cover 1 through the positive pole injection molded part 4. The positive pole pole 2 is provided with a positive pole groove 21. The positive pole groove 21 extends along the circumferential direction of the positive po...

Embodiment 2

[0064] Refer below Figure 4-Figure 6 A power battery cover plate according to another specific embodiment of the present invention is described.

[0065] like Figure 4-Figure 6 As shown, the power battery cover plate of this embodiment includes a top cover 1, a positive pole 2 and a negative pole 3, the top cover 1 is provided with two through holes 11, and the positive pole 2 and the negative pole 3 are respectively installed in the two through holes. Inside hole 11. The positive pole 2 is an aluminum pole, the negative pole 3 includes an aluminum part 31 and a copper part 32 , the copper part 32 fits on the big end of the through hole 11 , and the aluminum part 31 fits on the small end of the through hole 11 .

[0066] The positive column 2 is riveted on the top cover 1 through the positive pressing block 5, the positive pressing block 5 includes a first pressing block 51 and a first insulator 52, the first pressing block 51 is sleeved on the positive pole 2, and the pos...

Embodiment 3

[0069] like Figure 9-Figure 11 A power battery cover plate according to another specific embodiment of the present invention is described.

[0070] The structure of the power battery cover plate of this embodiment is substantially the same as that of Embodiment 2, the difference is that the first pressing block 51 of this embodiment is directly fitted into the first groove 521 of the first insulating member 52, and the second The two pressing blocks 71 are directly engaged in the second groove 721 of the second insulating member 72 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com