Low-cost and high-efficiency preparation method of steel/magnesium laminar composite plate strip

A composite plate strip, low-cost technology, applied in the field of steel/magnesium/steel layered composite plate strip, steel/magnesium layered composite plate strip with low cost and high efficiency, steel/magnesium layered composite plate strip, It can solve the problems of large coil weight, limited width and length, high equipment requirements, etc., achieve high interface bonding strength, reduce the requirements of the rolling mill, and achieve the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

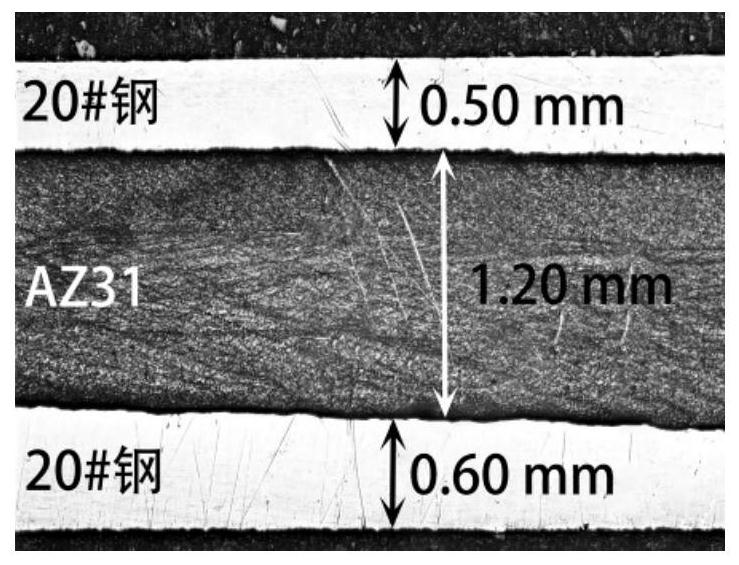

[0039] The 20# steel strip blank with a thickness of 1mm and the AZ31 magnesium alloy strip blank with a thickness of 1mm are used as raw materials to prepare 20# steel / AZ31 magnesium alloy / 20# steel layered composite plate strip .

[0040] The 20# steel strip and the AZ31 magnesium alloy strip are softened and annealed respectively. The softening and annealing system of the 20# steel strip is 910°C for 1h furnace cooling, and the softening annealing system for the AZ31 magnesium alloy strip is 350°C. 5h furnace cooling;

[0041] Use an angle grinder equipped with louvers to perform off-line mechanical grinding on the surface of the 20# steel strip blank and the AZ31 magnesium alloy strip blank to be compounded, remove the pollutants and oxide layer on the surface to be compounded, and obtain a clean and rough surface to be compounded , the direction of the grinding stripes formed by mechanical grinding is perpendicular to the length direction of the 20# steel strip blank and...

Embodiment 2

[0049] 20# steel / pure magnesium layered composite strips were prepared from 20# steel strips with a thickness of 2mm and pure magnesium strips with a thickness of 2mm and 10mm respectively.

[0050] Soft annealing treatment is carried out on 20# steel strip and pure magnesium strip respectively. The softening annealing system of 20# steel strip is 900℃ for 2h furnace cooling, and the softening annealing system for pure magnesium strip is 360℃ for 4h. cold;

[0051] Use an angle grinder equipped with a grinding wheel to perform off-line mechanical grinding on the surface of the 20# steel strip blank and the pure magnesium strip blank with a thickness of 2 mm to remove the pollutants and oxide layer on the surface to be composited, and obtain a clean and rough surface. Composite surface, the direction of the grinding stripes formed by mechanical grinding is perpendicular to the length direction of the 20# steel strip blank and the pure magnesium strip blank;

[0052] The 20# st...

Embodiment 3

[0059] Q235 steel strips with a thickness of 1mm in coils and ZK60 magnesium alloy strips with a thickness of 1mm and 2mm in coils are used as raw materials to continuously prepare Q235 steel / ZK60 magnesium alloy / Q235 steel in coils Laminated composite panel strip.

[0060] Soft annealing treatment is carried out on Q235 steel strips and ZK60 magnesium alloy strips in coil form respectively. The softening annealing system of 20# steel strips is furnace cooling at 890°C for 2 hours, and the softening annealing system of ZK60 magnesium alloy strips is 370 ℃ heat preservation 5h furnace cooling;

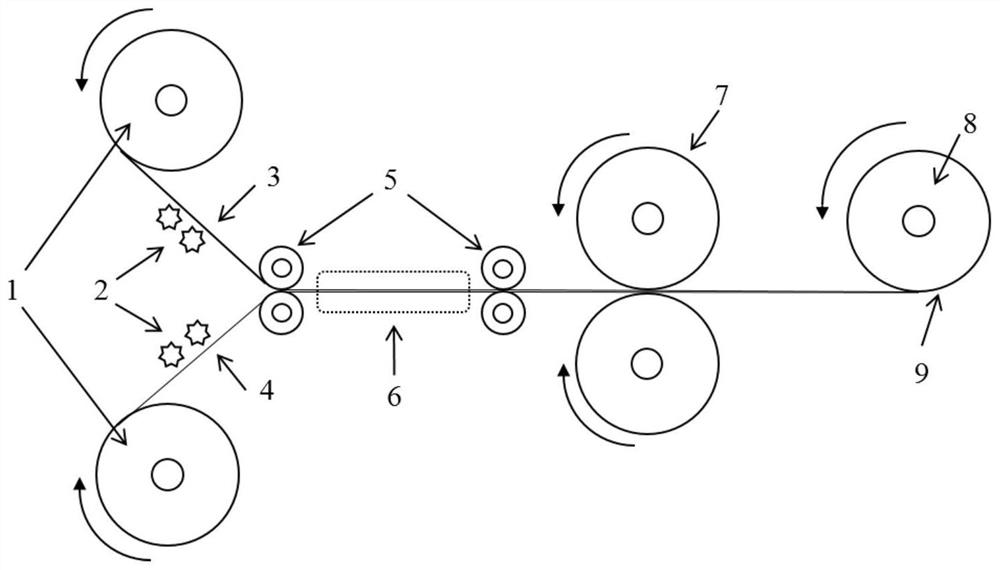

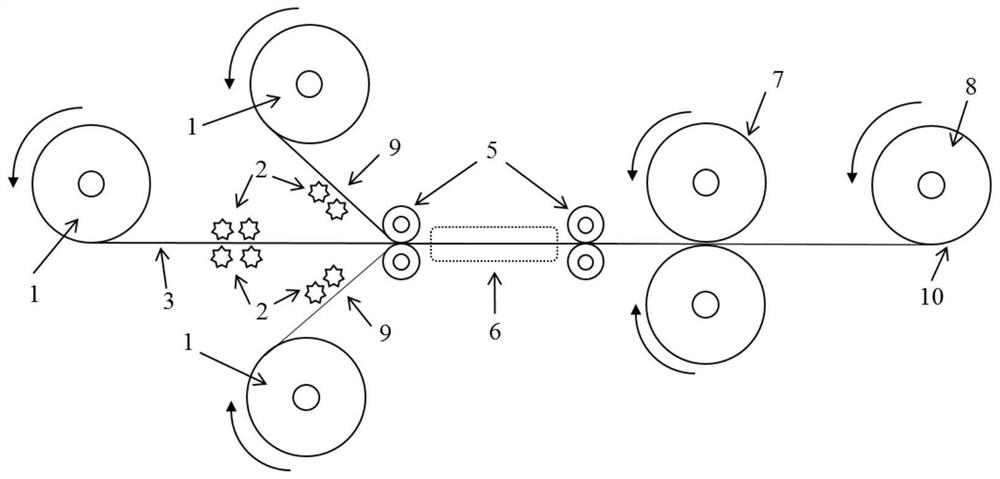

[0061] Use uncoiling equipment 1 to uncoil Q235 steel strips with a thickness of 1mm in coils and ZK60 magnesium alloy strips with a thickness of 1mm in coils, and use online grinding equipment 2 equipped with louvers to respectively uncoil ZK60 magnesium On-line mechanical grinding of alloy strip blank and Q235 steel strip blank to be compounded surface to remove pollutants and oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com