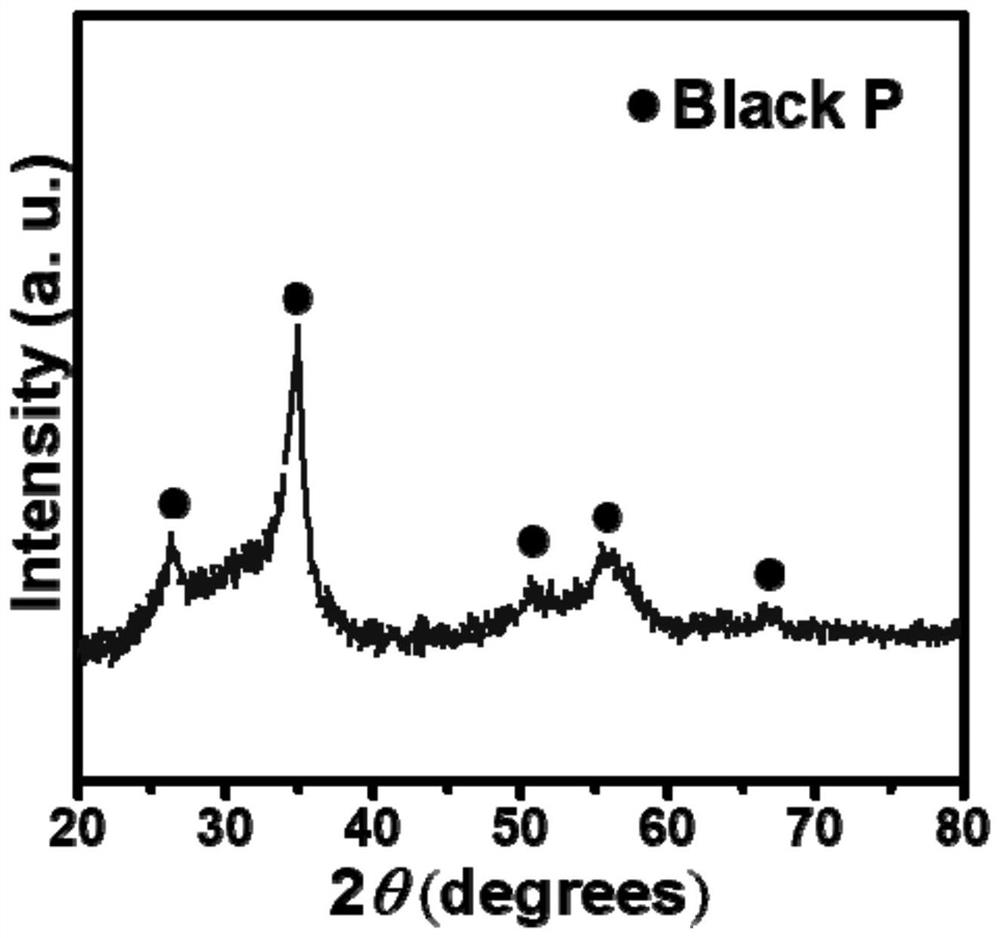

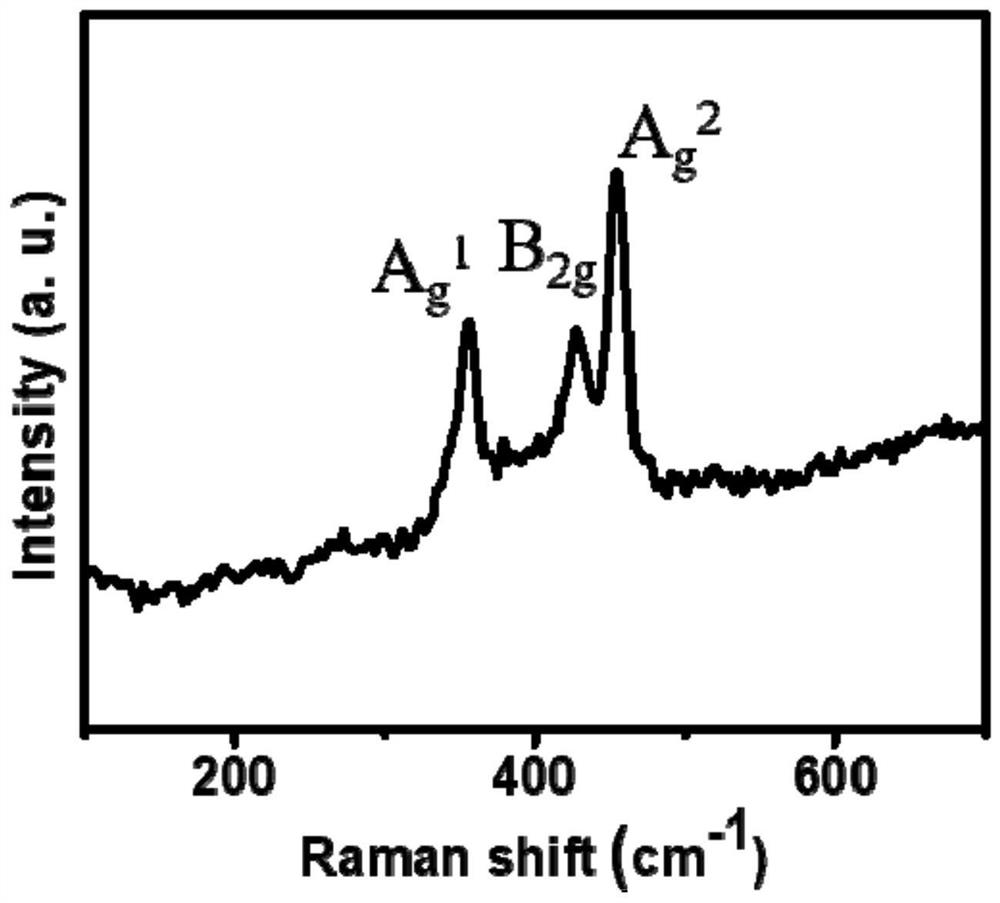

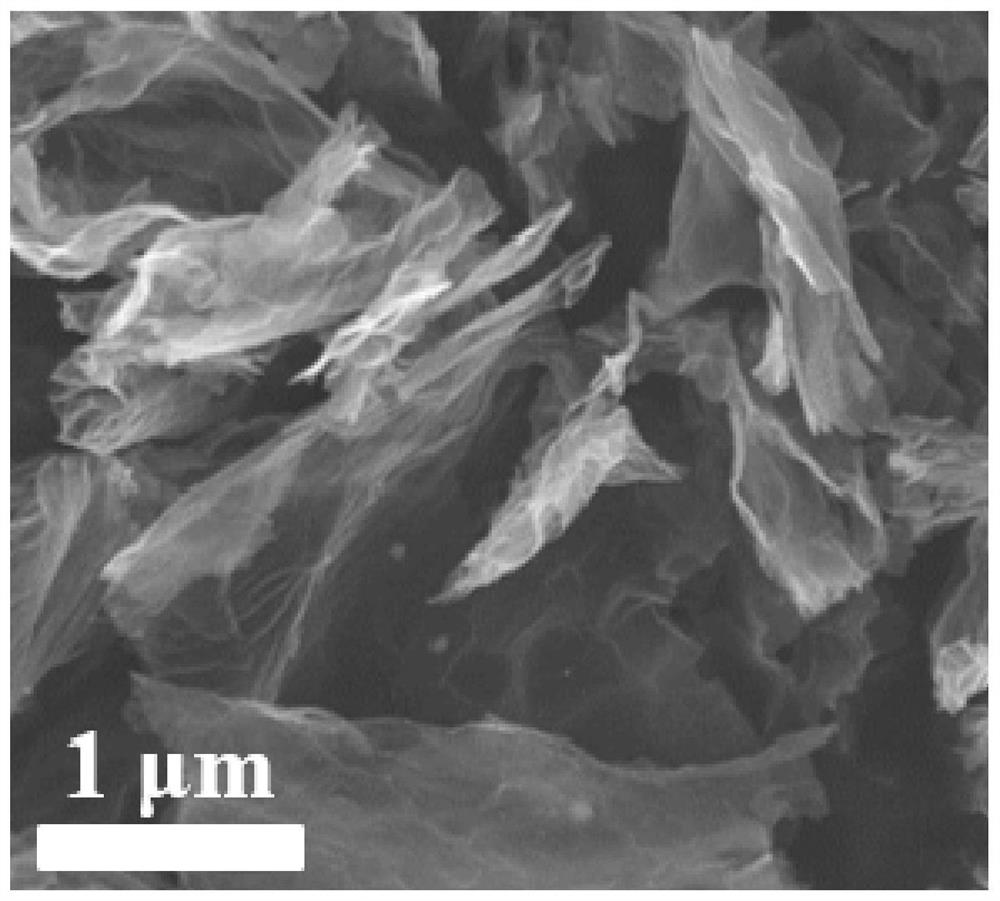

Synthetic method of porous black phosphorus nanosheet for negative electrode material of ion battery

A negative electrode material and ion battery technology, applied in battery electrodes, negative electrodes, nanotechnology, etc., can solve problems such as harsh synthesis conditions, complex two-dimensional black phosphorus nanosheets, and complex construction methods of porous black phosphorus nanosheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] DETAILED DESCRIPTION a: Porous black phosphorus present embodiment nanosheet method of synthesis for battery anode material, it is carried out the following steps:

[0023] First, the phosphorus, anhydrous chloride and sodium sodium sodium were added to the stainless steel ball mill, and the ball mill was 30 min to 100 min to obtain a ball mill mixture;

[0024] The molar ratio of the metal sodium and phosphorus (2 to 4): 1; the molar ratio of the anhydrous chloride and phosphorus phosphorus is 1: (5 ~ 20);

[0025] Second, the ball mill mixture is added to ethanol, soaked for 10 min to 30 min, then placed in dilute hydrochloric acid, soaked for 10 min to 30 min, finally used deionized water, obtained the product after cleaning, and the product was separated, and finally vacuum Dry, give a porous black phosphorus nanofile.

[0026] Advantageous Effects of the present embodiment is:

[0027] Conventional synthetic methods black phosphorus is red phosphorus as a starting mate...

specific Embodiment approach 2

[0030] DETAILED Embodiment 2: This embodiment and the exemplary first embodiment except that: a step a in the milling speed was 100rpm / min ~ 300rpm / min and the ball to powder ratio (5 ~ 10): under condition 1, milling 30min ~ 100min. Other specific embodiments the same as a.

specific Embodiment approach 3

[0031] DETAILED Embodiment 3: Embodiment of the present embodiment and the exemplary embodiment a one or two exceptions: the concentration of dilute hydrochloric acid in the procedure of 0.5mol / L ~ 2mol / L. Other specific embodiments of the same one or two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com