Brazing method of tungsten-copper alloy and chromium-zirconium-copper alloy

A technology of tungsten-copper alloy and brazing method, which is applied in welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex sintering process, high welding cost and high sintering temperature of tungsten-copper alloy, and avoid a large drop , low cost and low soldering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

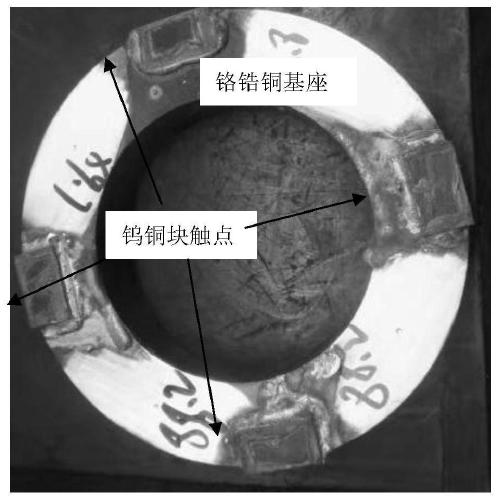

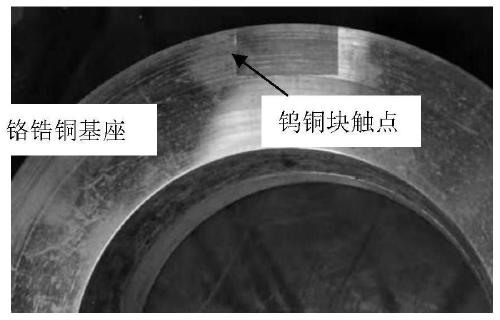

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: a kind of brazing method of tungsten-copper alloy and chromium-zirconium-copper alloy of the present embodiment is carried out according to the following steps:

[0027] 1. Before welding, polish the surface of the tungsten-copper block and the chrome-zirconium-copper base to be welded brightly, and use acetone as a cleaning agent to ultrasonically clean the two base materials to remove surface impurities;

[0028] 2. Fix the tungsten-copper block and chrome-zirconium-copper base cleaned in the previous step on the preheating table with clamps. The preheating temperature is 500-600°C, and the preheating time is 5-30 minutes;

[0029] 3. After preheating, use a flame spray gun to locally heat the surface to be welded of tungsten copper and chromium zirconium copper, and the flame will completely surround the part to be welded. When the temperature reaches the melting point of the flux, spread flux on the surface to be welded , and spread the flux...

specific Embodiment approach 2

[0040] Specific Embodiment 2: This embodiment is different from Specific Embodiment 1 in that: the thickness of the brazing filler metal layer reserved on the surface to be welded in Step 5 is 0.1-0.6 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: Embodiment 1 of this embodiment is different in that: the tungsten-copper alloy is WCu20, and the chromium-zirconium-copper alloy is CuCr1Zr. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com