Zn-Al-Mg-RE zinc ingot preparation method

A technology of zinc ingots and zinc pools, which is applied in the field of preparation of quaternary alloy zinc ingots, can solve the problems of inability to add rare earth elements well, does not conform to industrialized mass production, Mg elements and rare earths are prone to spontaneous combustion, etc., to avoid oxidation And the effect of spontaneous combustion phenomenon, reduction of preparation cost and good economic prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) prepare Zn-9.5wt%-5wt% La ternary master alloy:

[0023] Table 1. Raw materials used in Zn-9.5wt%Al-5wt%La ternary master alloy

[0024] the element

Zn

Al

La

Weight (g)

1323

147

83

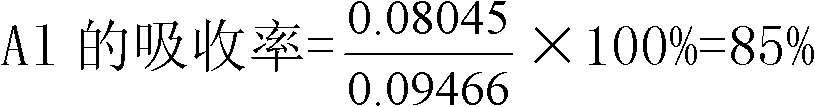

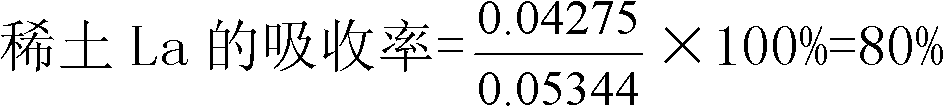

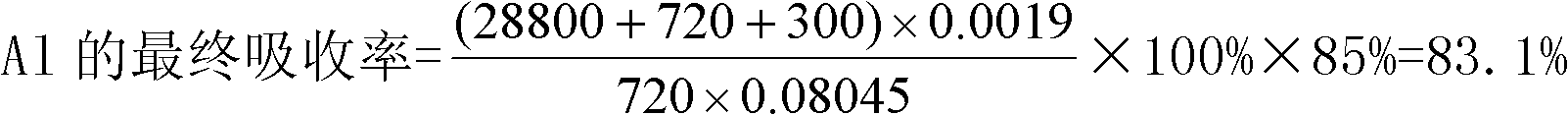

[0025] Materials used: Zn purity 99.99%, La purity 99%, Al purity 99.99%. The preparation process is as follows: First, polish off the oxide skin on the surface of 1323g pure zinc, and then put it into a high-purity graphite crucible in a resistance furnace for heating. The furnace temperature is set at 450°C, and the heating rate is about 7°C / min. Finally, set the furnace temperature to 500°C, add 147g of pure aluminum polished on the surface, let it stand for 40 minutes, set the furnace temperature to 540°C, and then put 83g of rare earth whose surface scale has been polished clean. Because the density of the rare earth is greater than that of the zinc liquid containing aluminum, the rare earth sinks into the zinc liquid, thereb...

Embodiment 2-3

[0046]The content of each element in the Zn-Al-Mg-La quaternary alloy zinc ingot prepared by Example 2-3 of the present invention is the same as that of Example 1, so the addition amount of raw materials is also the same, and the addition steps of each element are also the same, only the preparation The temperature control in the process is slightly different, and the specific parameters are shown in Table 5. What needs to be understood is that according to the needs of actual production and application, the content of each element in the Zn-Al-Mg-La quaternary alloy zinc ingot can be adjusted differently.

[0047] Table 5. The temperature control parameter of embodiment 2-3

[0048]

[0049] The experimental results found that the absorption rates of Al, La, and Mg are very similar, and the results are omitted here. The difference is that the temperature is lower and the dissolution rate is slightly slower. From an industrial point of view, in order to obtain high efficien...

Embodiment 4

[0064] (1) prepare Zn-9.5wt%-5wt%Ce ternary master alloy:

[0065] Table 8. Raw materials used in Zn-9.5wt%Al-5wt%Ce ternary master alloy

[0066] the element

Zn

Al

Ce

Weight (g)

1323

147

83

[0067] Materials used: Zn purity 99.99%, Ce purity 99%, Al purity 99.99%. The preparation process is as follows: First, polish off the oxide skin on the surface of 1323g pure zinc, and then put it into a high-purity graphite crucible in a resistance furnace for heating. The furnace temperature is set at 450°C, and the heating rate is about 7°C / min. Finally, set the furnace temperature to 500°C, add 147g of pure aluminum polished on the surface, let it stand for 40 minutes, set the furnace temperature to 540°C, and then put 83g of rare earth Ce whose surface scale has been polished clean, At this time, since the density of the rare earth is greater than that of the zinc liquid containing aluminum, the rare earth sinks into the zinc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com