A ceramic ball with a built-in α+β titanium alloy skeleton and its preparation method

A technology of β titanium alloy and ceramic ball, applied in the field of ceramic ball with built-in α+β titanium alloy skeleton and its preparation field, can solve problems such as restricting the development of cement ball milling, and achieve the purpose of avoiding ceramic fragmentation, convenient integrity and high formability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

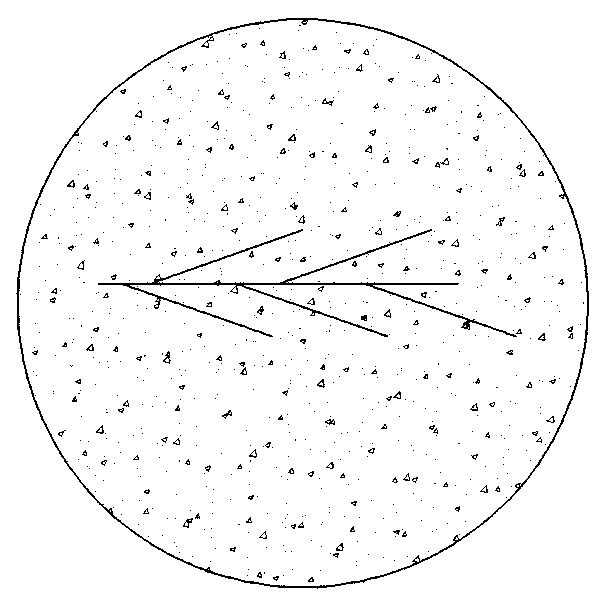

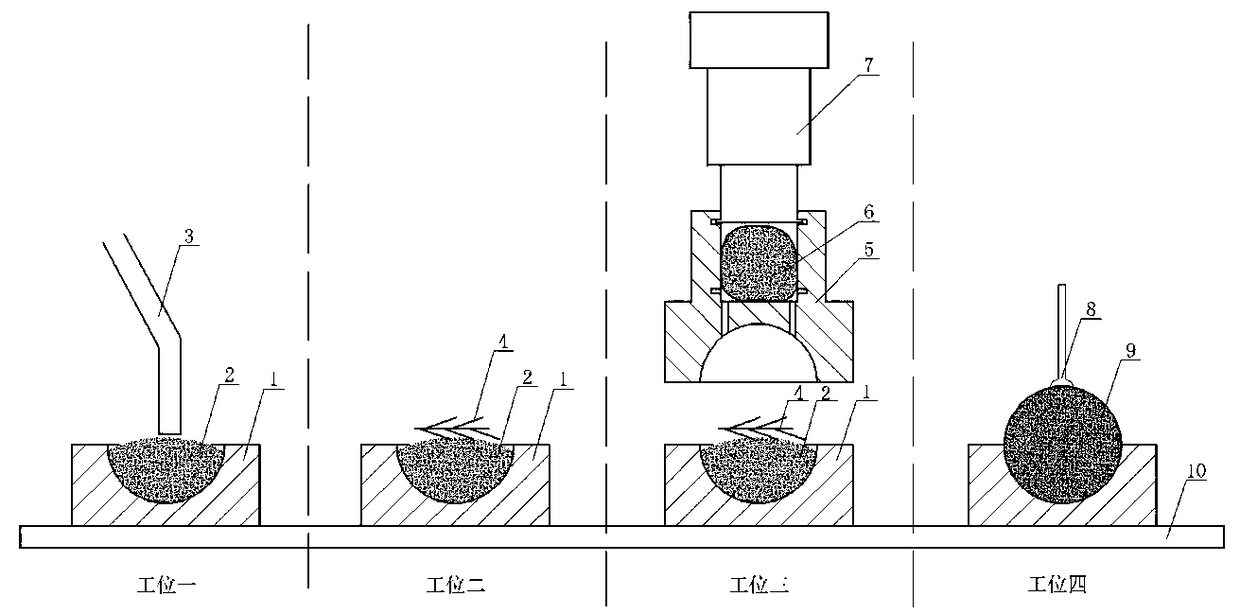

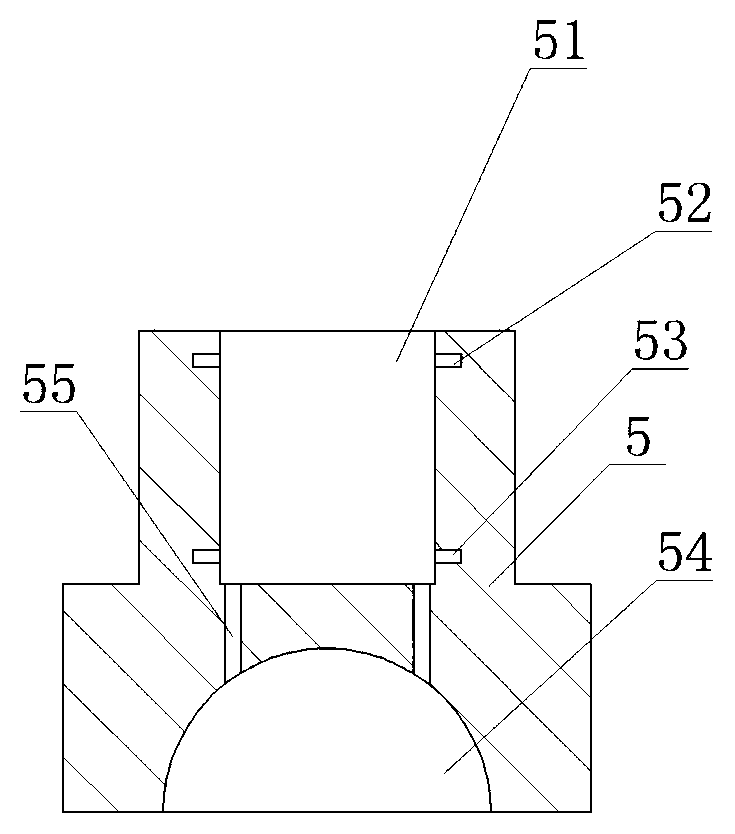

[0030] The ceramic ball with built-in α+β titanium alloy skeleton of the present invention, such as figure 1 As shown, it is composed of α+β titanium alloy integrally die-cast into an integral structure, dendritic or fishbone structure α+β titanium alloy skeleton and ceramic spheres wrapped around it, and is manufactured by integral pressing and high-temperature sintering; The total volume of the α+β titanium alloy skeleton is 3-5% of the volume of the ceramic ball, and the dimension in the longest direction is less than 70% of the outer diameter of the ceramic ball; the ceramic ball is made of alumina-based ceramic material, and its formula is alumina 92 -95%, ferric oxide 0.5-2%, kaolin 0.8-3%, silicon carbide 0.2-2%, titanium dioxide 1.5-2%, titanium carbide 0.8-1%, molybdenum disulfide 0.3-2%, the formula Embodiments and detailed proportions have been discussed in detail in the patents previously applied for by the inventor, and will not be repeated here. In the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com