Method for manufacturing gel polymer lithium ion battery

A technology of lithium-ion batteries and gel polymers, applied in secondary batteries, final product manufacturing, sustainable manufacturing/processing, etc., can solve incomplete polymerization of monomers, affect battery performance, fast charge and discharge performance and low temperature performance Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

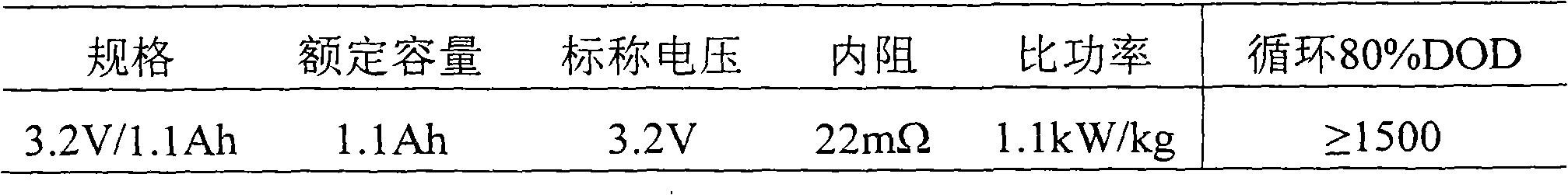

[0041] Example 1: Taking a 1.1Ah gel polymer battery as an example

[0042] 1. Slurry mixing:

[0043] Select spherical lithium iron phosphate D 50 Materials with a diameter of 3 μm and 7 μm respectively are used as positive electrode active materials, and the distribution ratio (wt%) of each component of the slurry is: lithium iron phosphate 90%, acetylene black 2.5%, conductive graphite 3%, styrene-butadiene rubber 3.5%, carboxymethyl Sodium cellulose 1%, appropriate amount of water. The distribution ratio (wt%) of each component of the negative electrode slurry is: 88.5% of modified graphite, 4% of conductive graphite, 6% of styrene-butadiene rubber, 1.5% of sodium carboxymethyl cellulose, and an appropriate amount of water.

[0044] The mixing method adopts continuous ultrasonic preparation technology of double planetary slurry mixing. Firstly, the active material is mixed for 2 hours by double planetary agitation, and then it is sprayed into the ultrasonic mixer through...

Embodiment 2

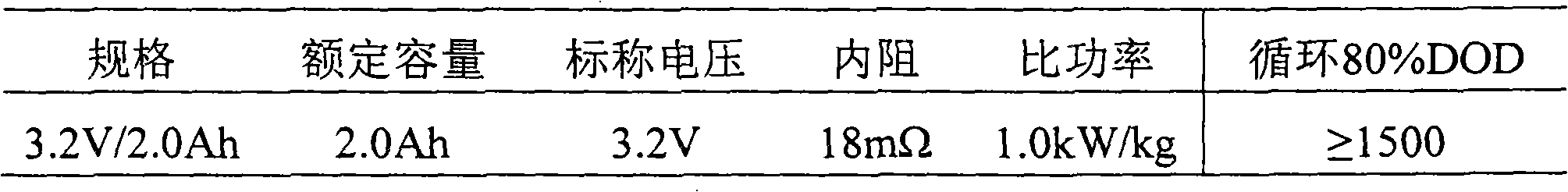

[0068] Example 2: Take a 2.0Ah gel polymer battery as an example

[0069] 1. Slurry mixing:

[0070] Choose flake lithium iron phosphate D 50 The materials with a diameter of 400nm, 3μm and 7μm respectively are positive electrode active materials, and the ratio is 1:2:1. The proportion (wt%) of each component of the positive electrode slurry is: 91% of lithium iron phosphate, 1.5% of acetylene black, 3.5% of conductive graphite, 3% of styrene-butadiene rubber, 1% of sodium carboxymethyl cellulose, and an appropriate amount of water. The distribution ratio (wt%) of each component of the negative electrode slurry is: 90% of modified graphite, 4% of conductive graphite, 4.5% of styrene-butadiene rubber, 1.5% of sodium carboxymethyl cellulose, and an appropriate amount of water.

[0071] The compounding adopts double-planetary slurry mixing continuous ultrasonic preparation technology. Firstly, the active material is preliminarily mixed for 3 hours by double-planetary agitation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com