WC particle reinforced composite brazing filler metal used for brazing hard alloy and preparation method thereof

A cemented carbide and particle-reinforced technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of hard alloy brazing joints such as easy wear, low working strength, and poor wettability , to achieve the effect of improving mechanical properties, ensuring performance stability, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

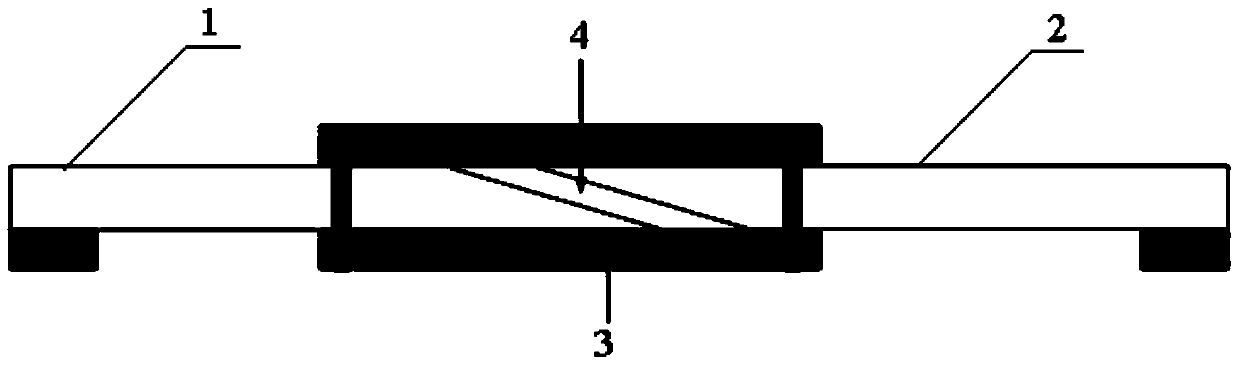

Method used

Image

Examples

specific Embodiment approach 1

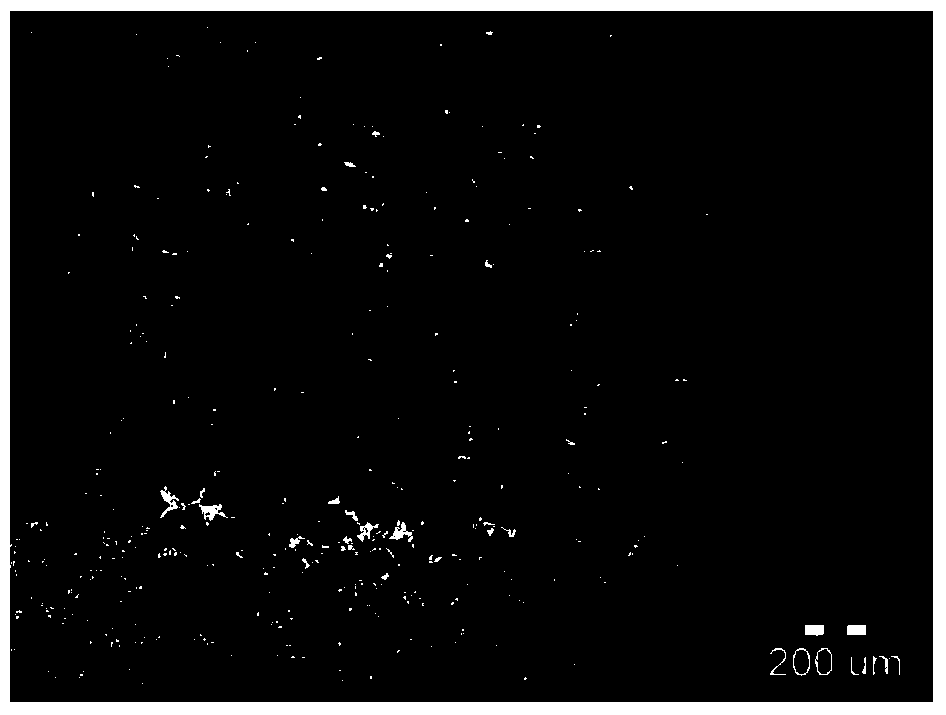

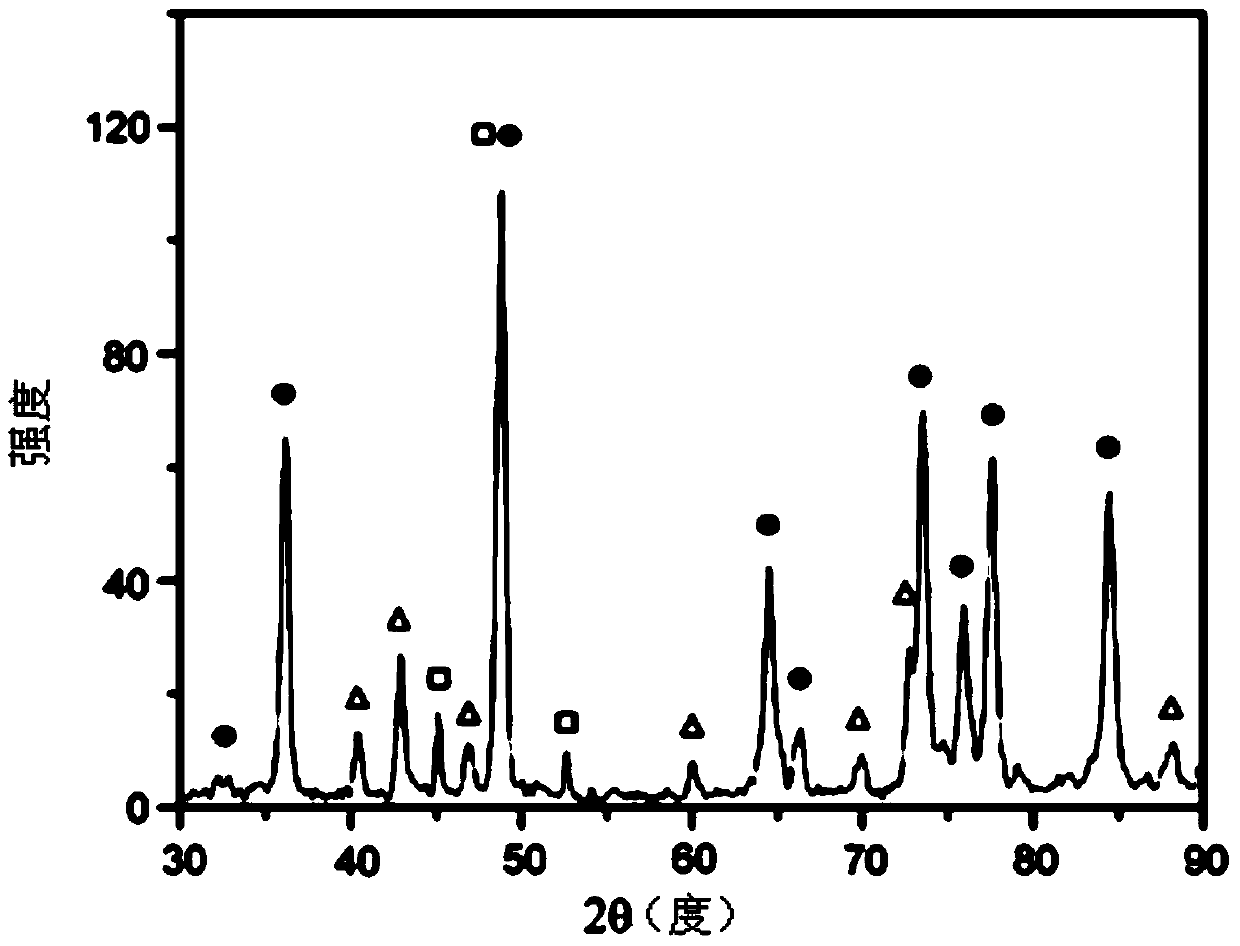

[0023] Specific embodiment 1: The WC particle-reinforced composite solder used in this embodiment for cemented carbide brazing consists of 0.01 to 20 parts of Al, 0.01 to 15 parts of Ti, and 20 to 70 parts of Al Ni, 1-20 parts of W, 1-10 parts of Co, 1-10 parts of Cr, 0.1-10 parts of B, 0.1-10 parts of Fe, 0.1-10 parts of Si powder and WC particles, the amount of WC particles added is 35% to 55% of the total volume of Al, Ti, Ni, W, Co, Cr, B, Fe, and Si powders.

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the WC particle reinforced composite solder of cemented carbide brazing consists of 1 part of Al, 3 parts of Ti, 30 parts of Ni, 5 parts by weight. W, 8 parts of Co, 5 parts of Cr, 3 parts of B, 7 parts of Fe, 6 parts of Si powder and WC particles, the amount of WC particles added is Al, Ti, Ni, W, Co , Cr, B, Fe, and Si powder 45% of the total volume. . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the addition of WC particles is 35% of the total volume of Al, Ti, Ni, W, Co, Cr, B, Fe, and Si powder ~55%. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com