Co-rail oil injection system electric control oil injector

A technology of electronically controlled fuel injection and fuel injection system, which is applied in the direction of charging system, machine/engine, fuel injection device, etc., and can solve the problem of inability to select the flow coefficient of the orifice, difficulty in controlling the tolerance of the gap A, and affecting the fuel injector. Performance and other issues, to achieve the effect of improving dynamic response characteristics, reducing the difficulty of manufacturing process, and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

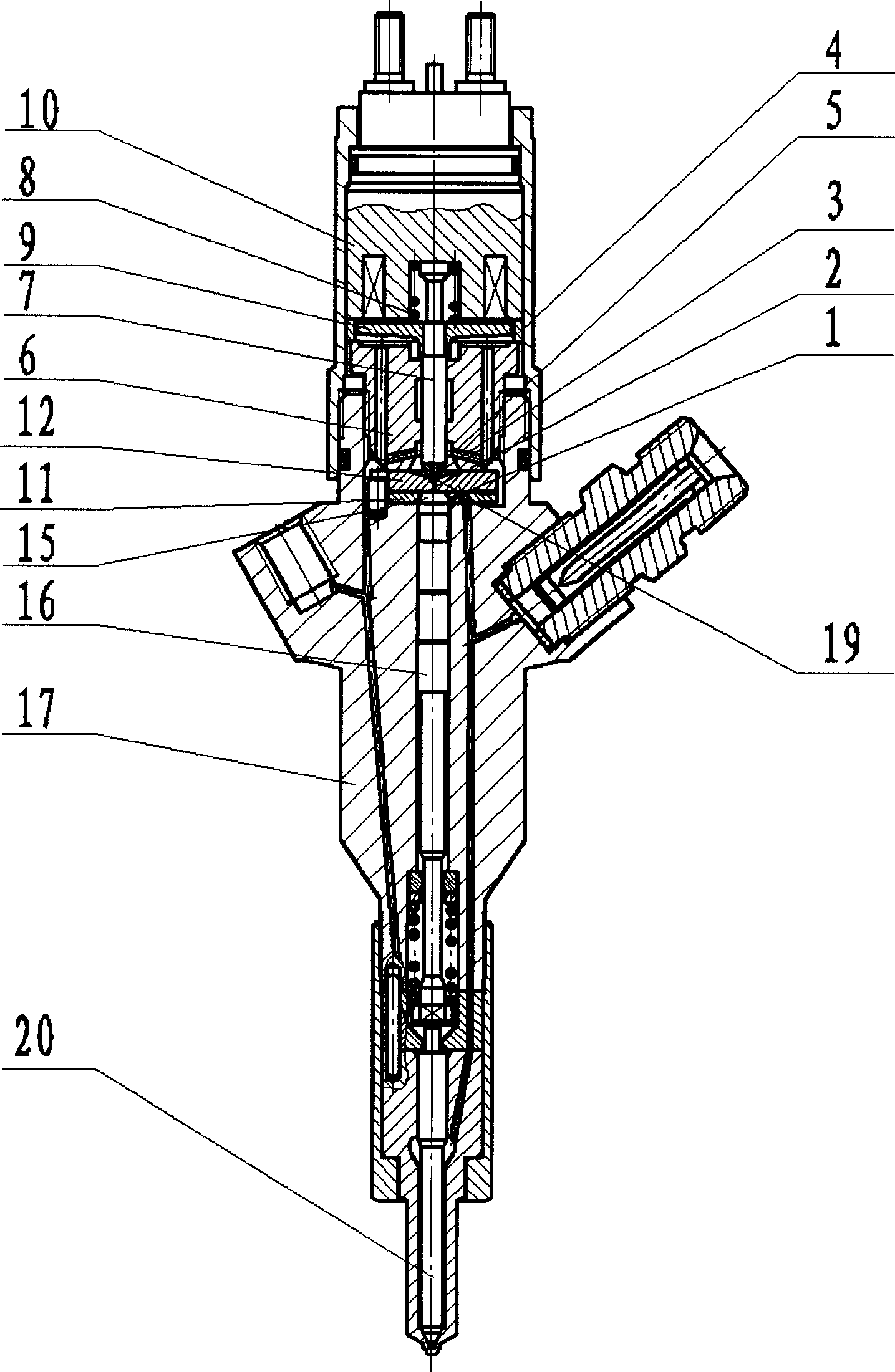

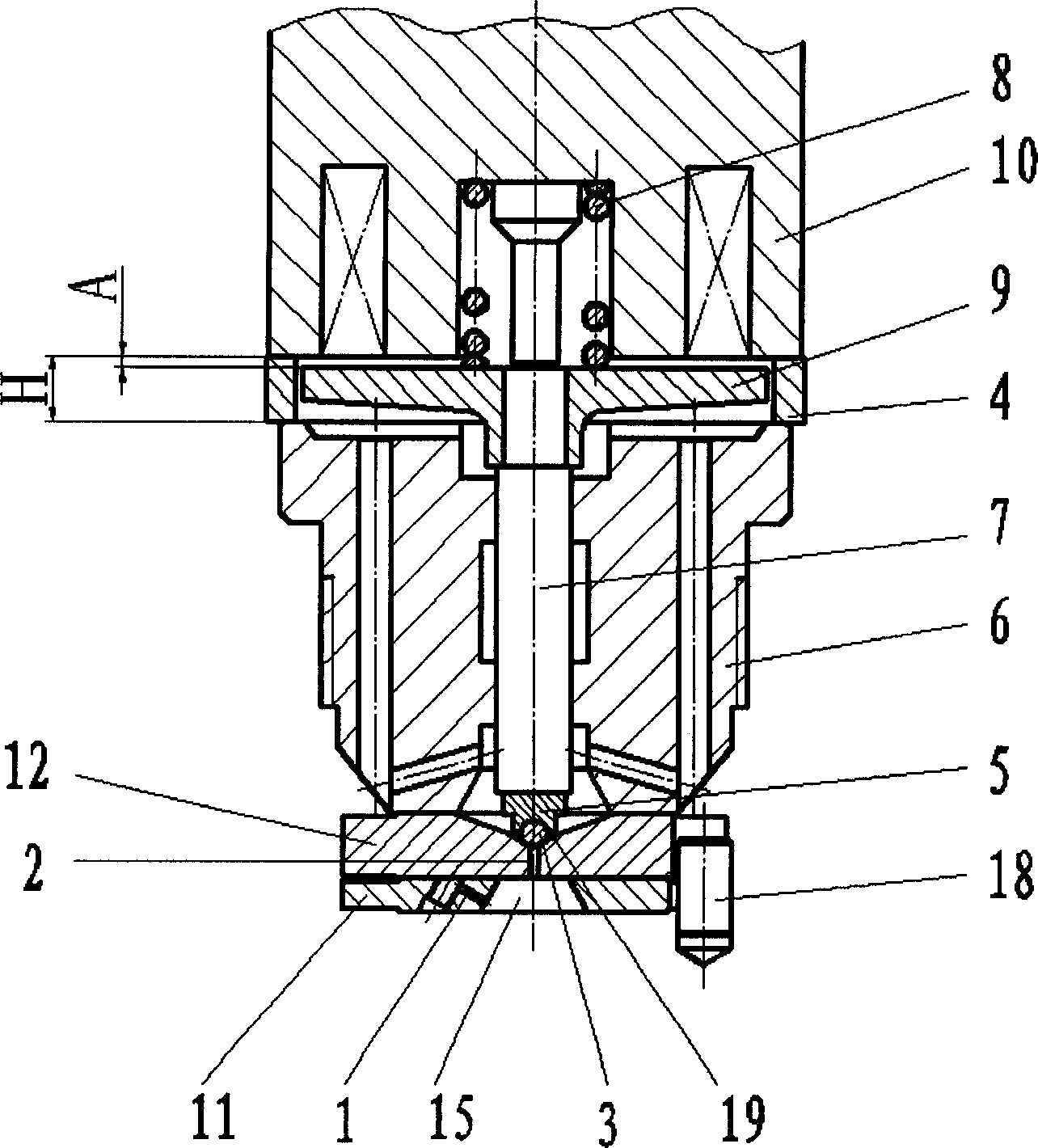

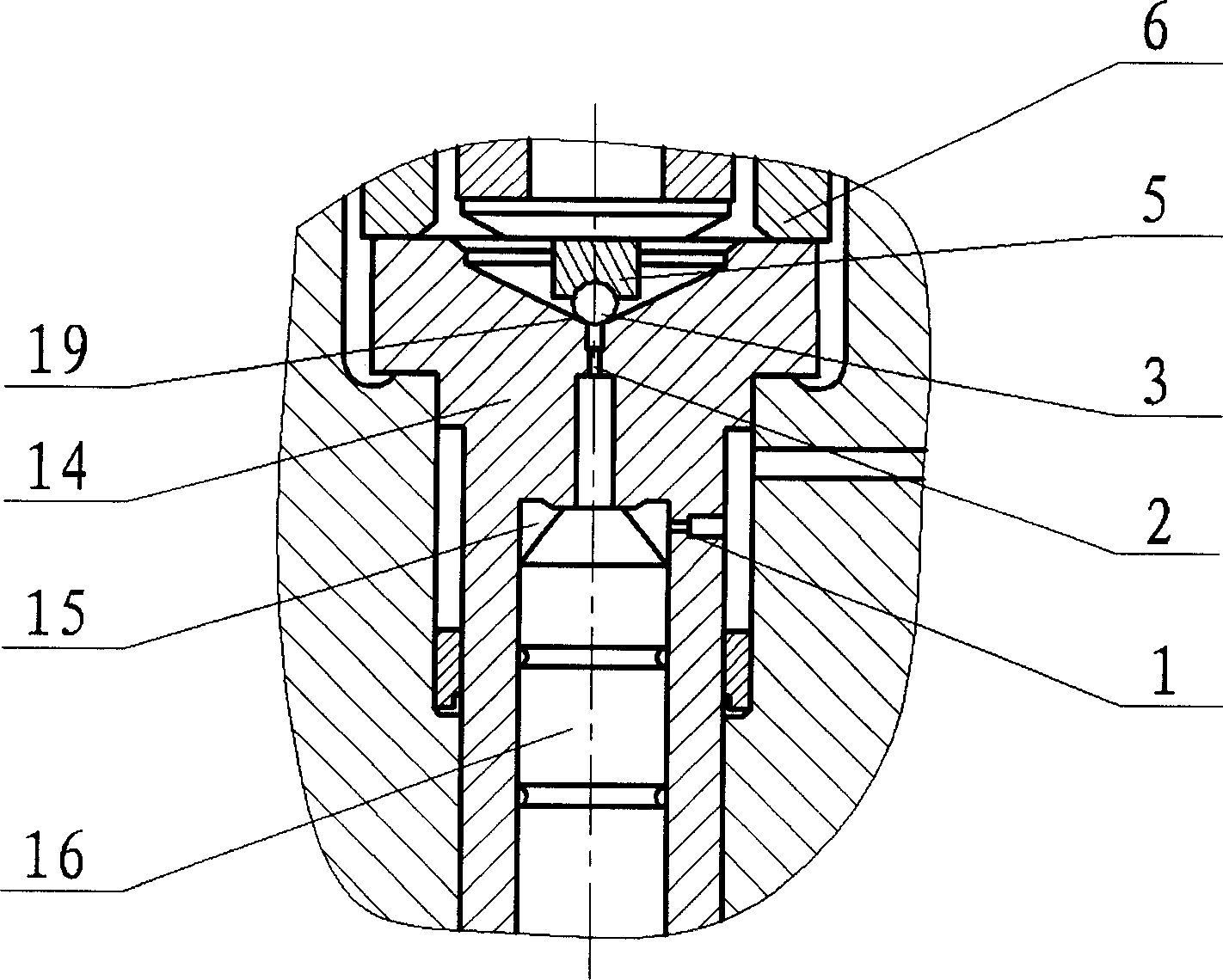

[0009] figure 1 It is a cross-sectional view of an electronically controlled fuel injector of a common rail fuel injection system that adopts the technical solution of the present invention. figure 2 It is an enlarged view of the control valve part, which includes parts and structural elements: electromagnet parts (10), armature (9), spring (8), armature rod (7), control valve seat (6), ball Seat (5), adjusting ring (4), valve ball (3), orifice positioning pin (18), and orifice plate (11) processed with oil inlet orifice (1), and processed with oil return The orifice (2) and the large orifice plate (12) of the sealing cone (19). The pressure control chamber (15) is located at the middle hole of the throttle orifice plate (11). The orifice plate positioning pin (18) is used to fix the circumferential position of the orifice plate (11 and 12). The large throttling orifice plate (12) is installed between the small throttling orifice plate (11) and the control valve seat (6), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com