On-line spray descaling method and system for diesel engine exhaust gas recirculation cooler

A technology for exhaust gas recirculation and diesel engine, applied in exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems of pollution, effective conversion of unfavorable carbon deposits, and severe temperature changes, and achieve the effect of ensuring performance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

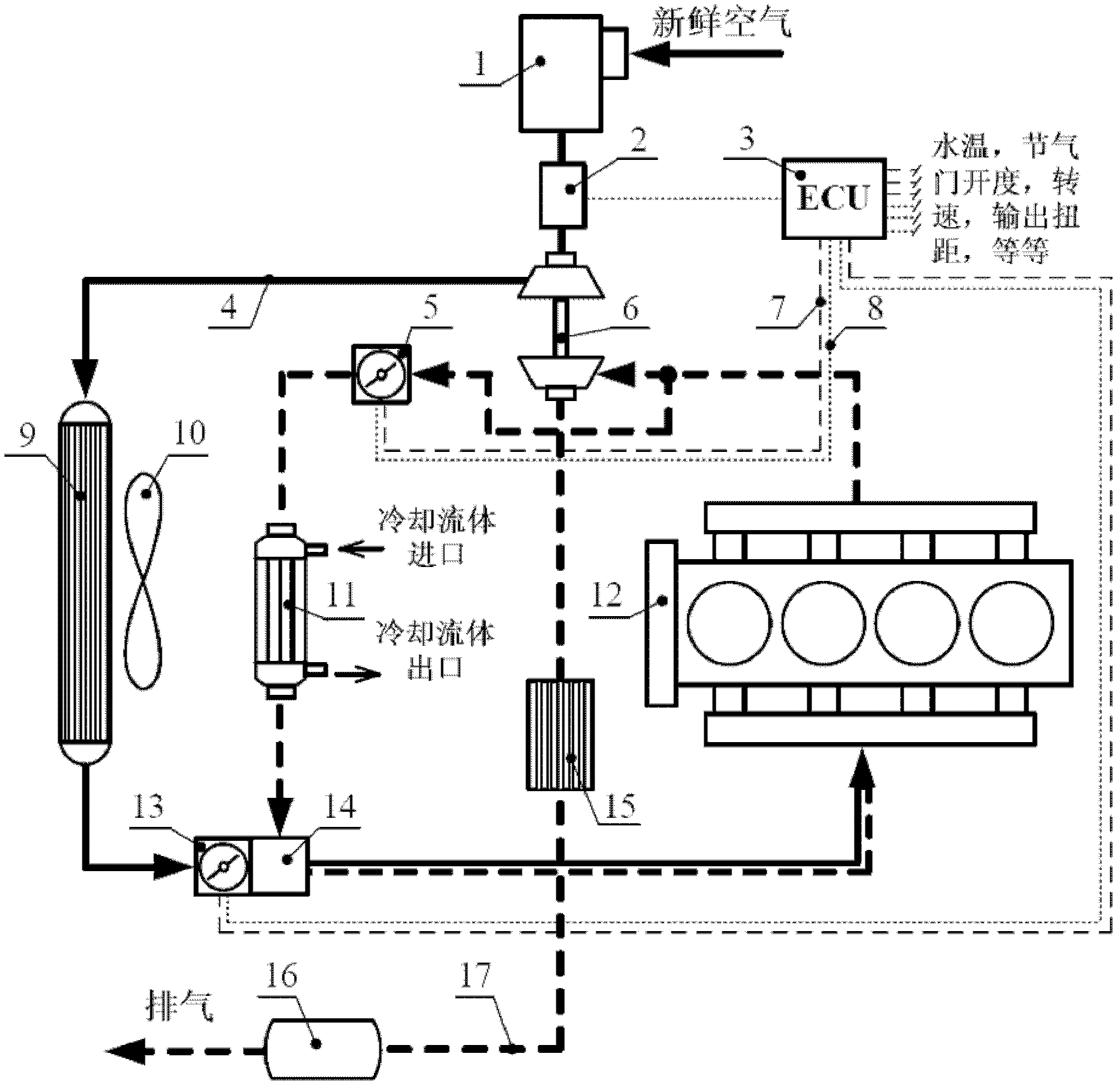

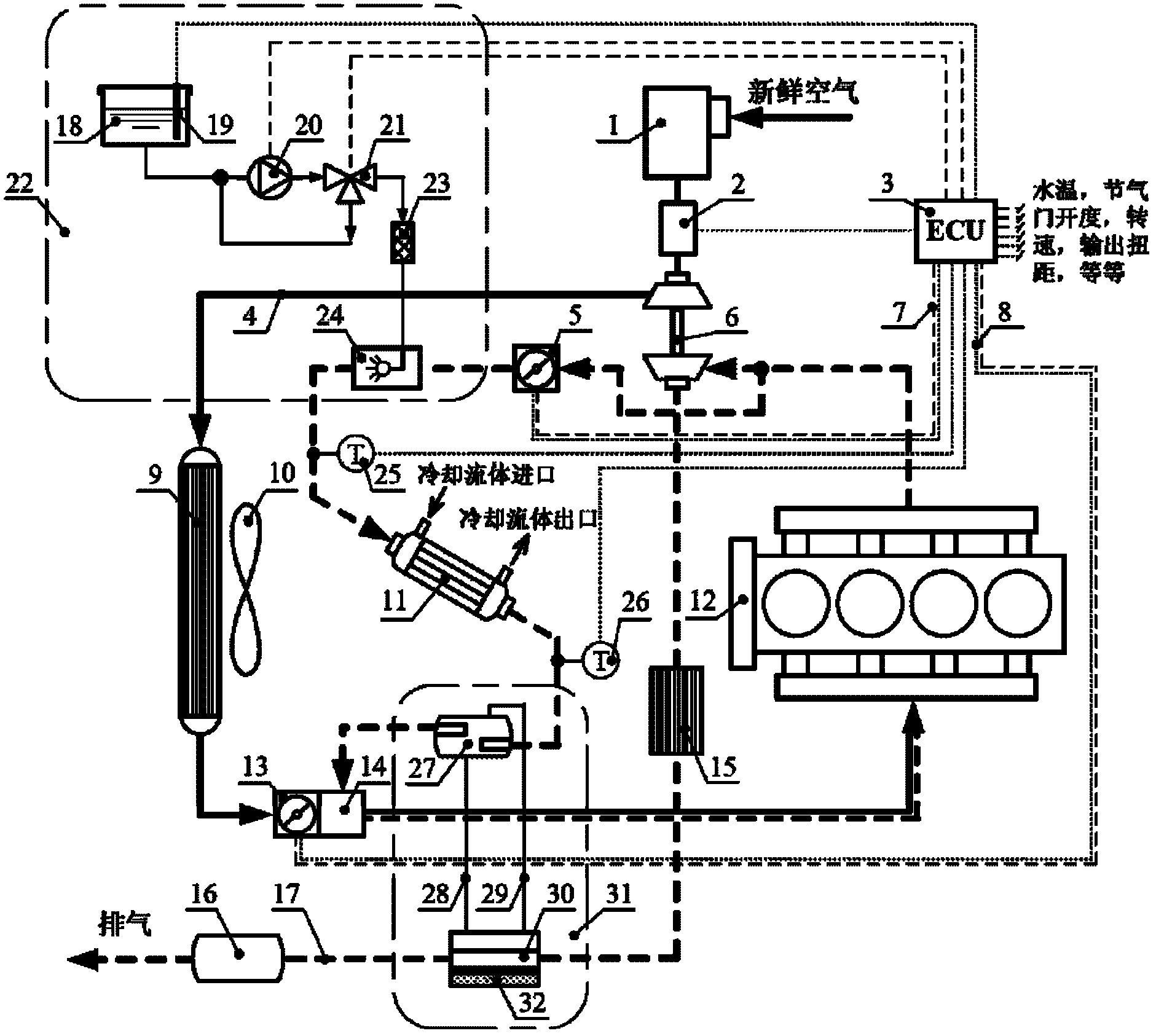

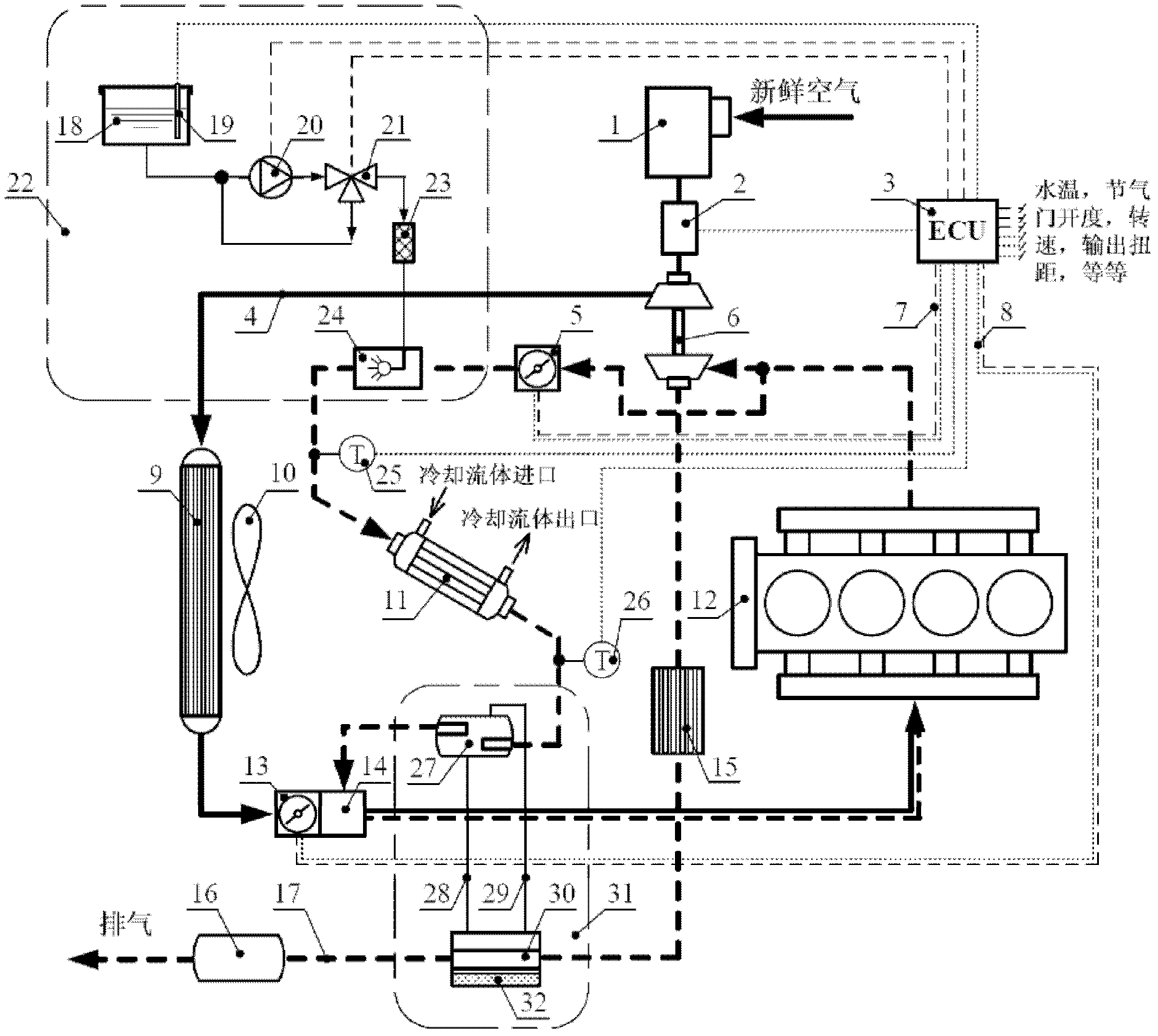

[0021] The principle of the inventive method is as follows:

[0022] The average molecular formula of diesel is C 15 h 28 , the chemical reaction equation for complete combustion is:

[0023] C 15 h 28 +22O 2 →15CO 2 +14H 2 o

[0024]Water accounts for a large proportion of the reaction product, that is, the moisture content of the diesel engine combustion exhaust gas is significantly higher than that of the intake air. When the combustion excess air coefficient is 2, the increment is about 41g / kg dry air. On this basis, through the spraying method, the latent heat of vaporization of water is used to absorb the heat of exhaust gas, which can greatly reduce the temperature of exhaust gas, and further increase its moisture content to make it saturated. Take the following working conditions as an example: the intake air temperature of the exhaust gas recirculation cooler is 500°C, the gauge pressure is 250kPa, and the moisture content of the intake air is 20g / kg dry air;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com