Glass powder, positive silver paste, and preparation methods therefor

A technology of glass powder and silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc. It can solve the problems of lead-containing silver paste and improve solderability and tension, to achieve applicability, to ensure the effect of performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 11), preparation of organic vehicle: take mass percentage as 15% ethyl cellulose resin, mass percentage as 8% rosin resin, mass percentage as 10% phenolic resin, add mass percentage as 67% solvent (propylene glycol methyl ether acetate, pine One or more mixtures of oleyl alcohol, ethylene glycol monobutyl ether acetate, turpentine, butyl carbitol, and petroleum ether) are dissolved at a temperature of 80-150°C while stirring while heating, and after 2 hours A uniform and transparent organic carrier can be obtained.

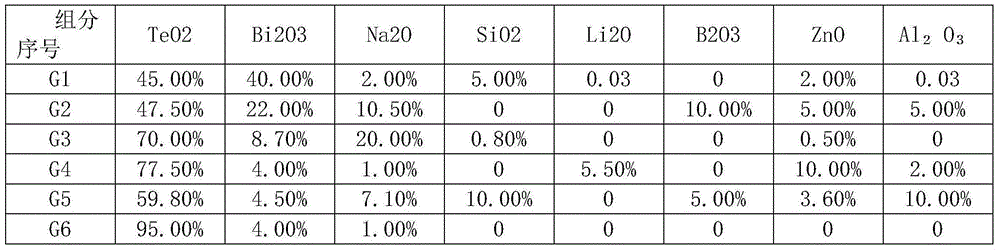

[0039] 12) Preparation of glass powder: Take the G1 formula glass powder in the above table 1, mix the above-mentioned raw materials that have been weighed evenly with a mixer, and then place them in a high-temperature muffle furnace. The temperature is controlled at 600 ° C ~ 1200 ° C 1 hour. The melted glass melt is poured into deionized water and quenched, ball milled to 1um and then sieved through a 325-400 mesh screen to obtain suitable glass powder f...

Embodiment 2

[0043] 21), preparation of organic vehicle: take mass percentage as 15% ethyl cellulose resin, mass percentage as 5% rosin resin, mass percentage as 10% phenolic resin, add mass percentage as 70% solvent (propylene glycol methyl ether acetate, pine One or more mixtures of oleyl alcohol, ethylene glycol monobutyl ether acetate, turpentine, butyl carbitol, and petroleum ether) are dissolved at a temperature of 80-150°C while stirring while heating, and after 2 hours A uniform and transparent organic carrier can be obtained.

[0044] 22) Preparation of glass powder: Take the G2 formula glass powder in the above table 1, mix the above-mentioned raw materials that have been weighed evenly with a mixer, and then place them in a high-temperature muffle furnace. The temperature is controlled at 600 ° C ~ 1200 ° C 1 hour. The melted glass melt is poured into deionized water and quenched, ball milled to 1um and then sieved through a 325-400 mesh screen to obtain suitable glass powder f...

Embodiment 3

[0048] 31), preparation of organic vehicle: take mass percentage as 7% ethyl cellulose resin, mass percentage as 5% rosin resin, mass percentage as 15% phenolic resin, add mass percentage as 73% solvent (propylene glycol methyl ether acetate, pine One or more mixtures of oleyl alcohol, ethylene glycol monobutyl ether acetate, turpentine, butyl carbitol, and petroleum ether) are dissolved at a temperature of 80-150°C while stirring while heating, and after 2 hours A uniform and transparent organic carrier can be obtained.

[0049] 32) Preparation of glass powder: Take the G3 formula glass powder in the above table 1, mix the above-mentioned raw materials that have been weighed evenly through a mixer, and then place them in a high-temperature muffle furnace. The temperature is controlled at 600 ° C ~ 1200 ° C 1 hour. The melted glass melt is poured into deionized water and quenched, ball milled to 1um and then sieved through a 325-400 mesh screen to obtain suitable glass powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com