Waterproof greasy-dirt-resisting 10 kV middle-voltage transducer cable and method

A frequency converter and oil-resistant technology, which is applied in the direction of power cables with shielding layers/conductive layers, cable/conductor manufacturing, circuits, etc., to achieve the effects of waterproof performance, safety, reduced adverse effects, and strong voltage shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

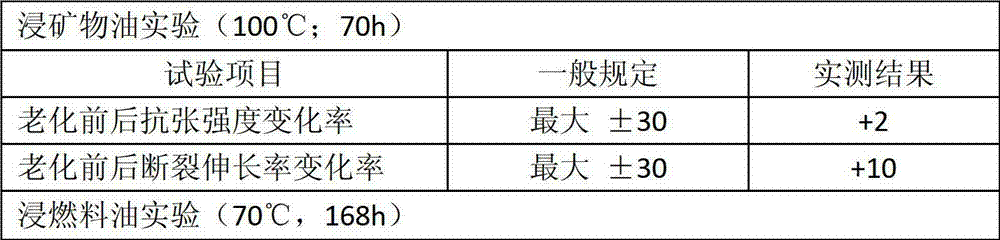

Examples

Embodiment 1

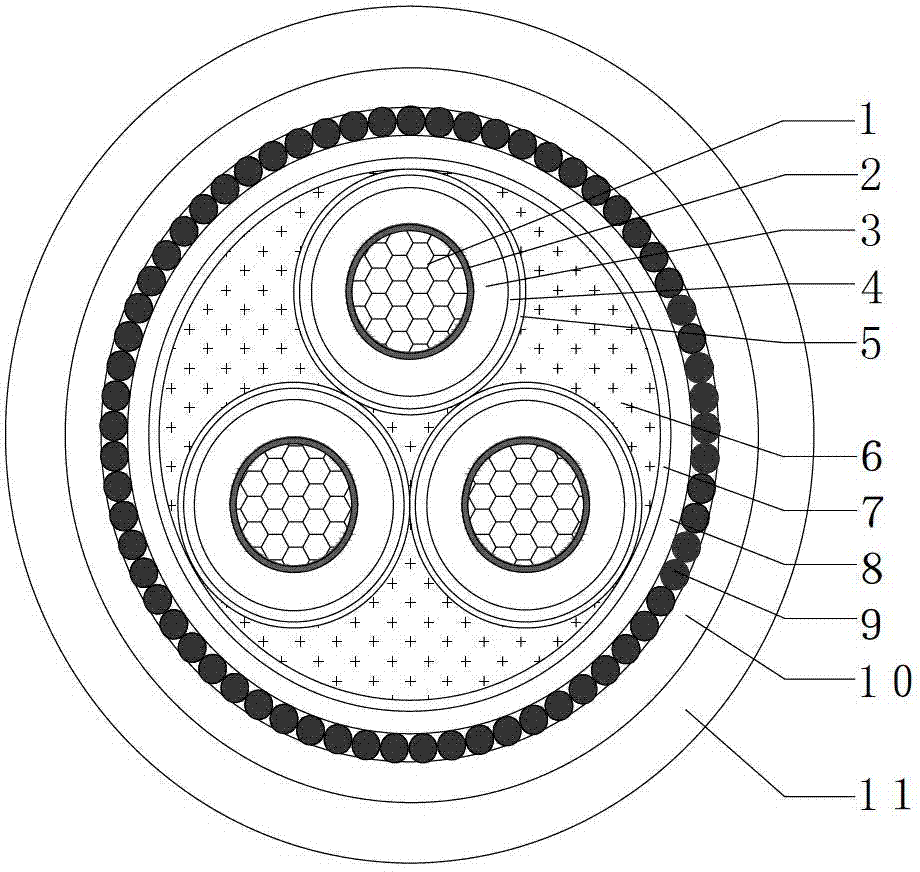

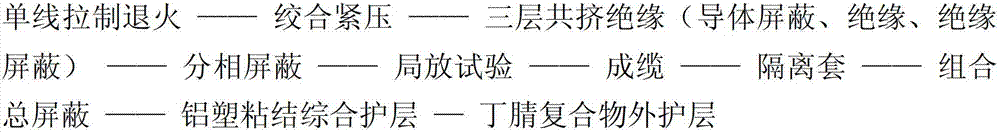

[0048] Embodiment 1 The structure of the cable provided by the present invention

[0049] The cable is composed of conductor 1, conductor shield 2, variable-link polyethylene insulation layer 3, insulation shield layer 4, phase-separated shield layer 5, filled water-blocking rope 6, wrapping water-blocking tape 7, and isolation sleeve from inside to outside. 8. The combined shielding layer 9 is composed of an aluminum-plastic bonded comprehensive sheath 10 and an outer sheath 11 of a nitrile compound.

[0050] Among them, (1) Conductor: copper conductor is selected as the conductor, and the conductor adopts a tightly compressed circular structure to prevent tip discharge.

[0051] (2) XLPE insulation layer: Considering the voltage level of the 10kV medium-voltage inverter cable, a three-layer co-extrusion process of conductor shielding, XLPE insulation, and insulation shielding is adopted to balance the electric field and improve the insulation performance of the cable.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com