Knob

A knob and rotation center technology, applied in the field of knobs, can solve problems such as poor contact, wear of contact pieces, short life, etc., to achieve the effects of ensuring performance stability, reducing positioning requirements, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

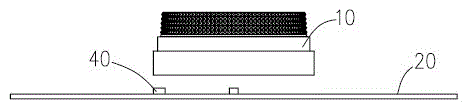

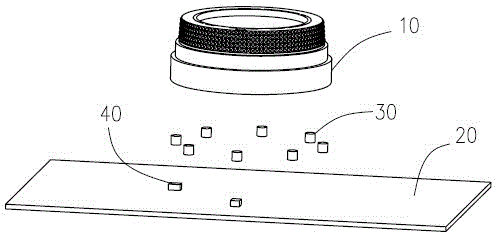

[0011] The knob of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0012] like Figure 1 to Figure 2 As shown, in one embodiment, the knob of the present invention mainly includes an operation cap (hereinafter referred to as the cap) 10, a circuit board 20 behind the cap, a plurality of magnetic particles 30 fixed inside the cap, and a plurality of magnetic particles fixed on the circuit board. (two or more) magnetic sensors 40 . When the cap 10 is operated in which the knob is turned, the cap 10 is not in contact with the circuit board 20 .

[0013] The cap 10 is used as an operating part of the knob, and is generally rotationally symmetrical, and may be hemispherical, cylindrical or ring-shaped. In this embodiment, the cap 10 is ring-shaped. The cap 10 is usually movably fixed on the casing of the device, and the circuit board 20 is fixed inside the casing of the device.

[0014] A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com