Hazardous waste rotary kiln incineration treatment process

A hazardous waste and treatment process technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as environmental pollution, insufficient combustion of hazardous waste, and unsatisfactory combustion, achieve sufficient mixing, curb odor and nitrogen oxides Effect of compound formation and inhibition of dioxin formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

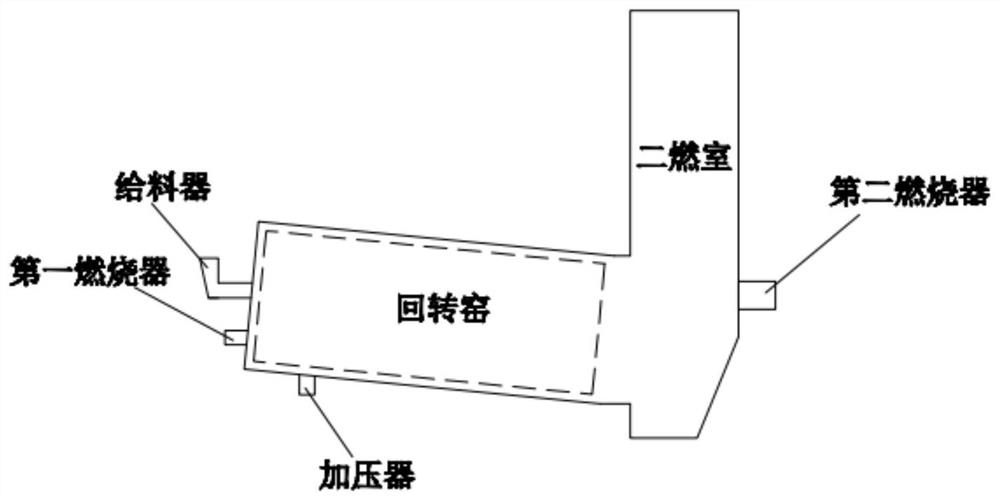

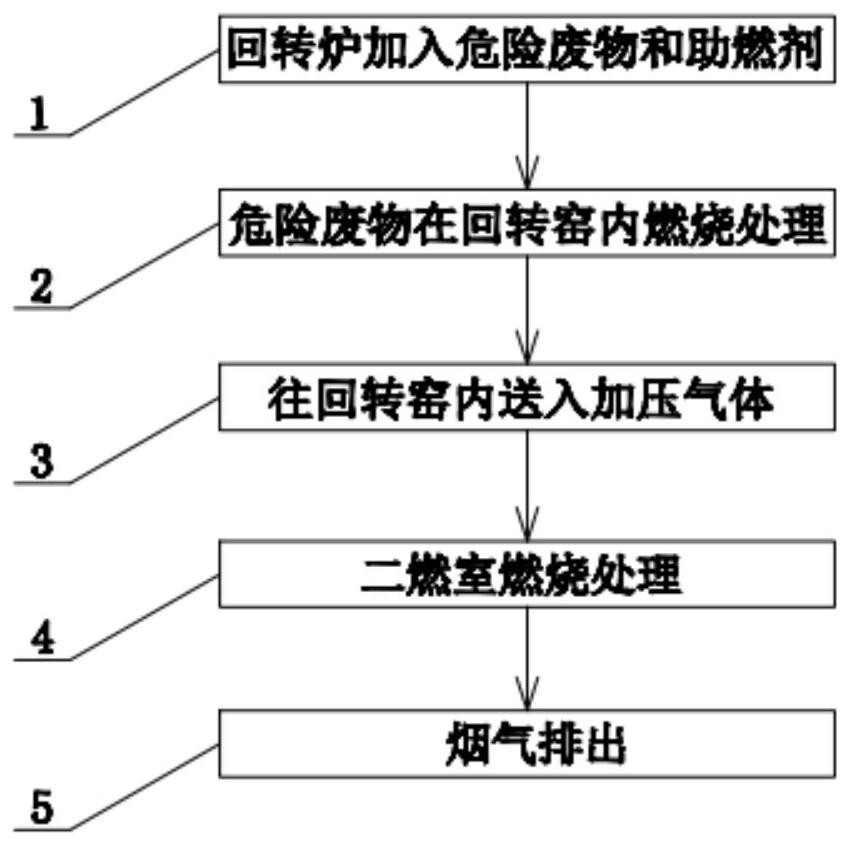

[0026] see Figure 1-Figure 2 Shown, the technical solution that this specific embodiment adopts is: it comprises the following steps:

[0027] Step 1, adding hazardous waste and combustion accelerant into the rotary kiln through the feeder;

[0028] Step 2, start the first burner and rotate the rotary kiln, and burn the hazardous waste in the rotary kiln;

[0029] Step 3, start the pressurizer, feed in pressurized gas, control the combustion temperature in the rotary kiln at 1200°C, and continue burning for 8 minutes;

[0030] Step 4: Start the second burner, and the combustibles processed by the rotary kiln enter the second combustion chamber for combustion treatment. The temperature in the second combustion chamber is controlled at 1200° C., and the residence time of the flue gas is 3 seconds.

[0031] Step 5, the flue gas combusted in the second combustion chamber is discharged from the top.

[0032] In the step 1, the angle between the central axis of the rotary kiln a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com