Hot-pipe type organic waste liquor treatment system

The technology of a pipe-arranging and air-distributing device is applied in the field of heat-pipe-type organic waste liquid treatment devices, which can solve problems affecting the long-term normal and continuous operation of an alcohol waste liquid concentrated liquid fluidized combustion furnace, the difficulty in controlling the temperature of the fluidized bed and the furnace chamber temperature, The reflection arch is easy to accumulate dust and other problems, so as to improve the comprehensive processing capacity, not easy to coking and dust accumulation, and easy to burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

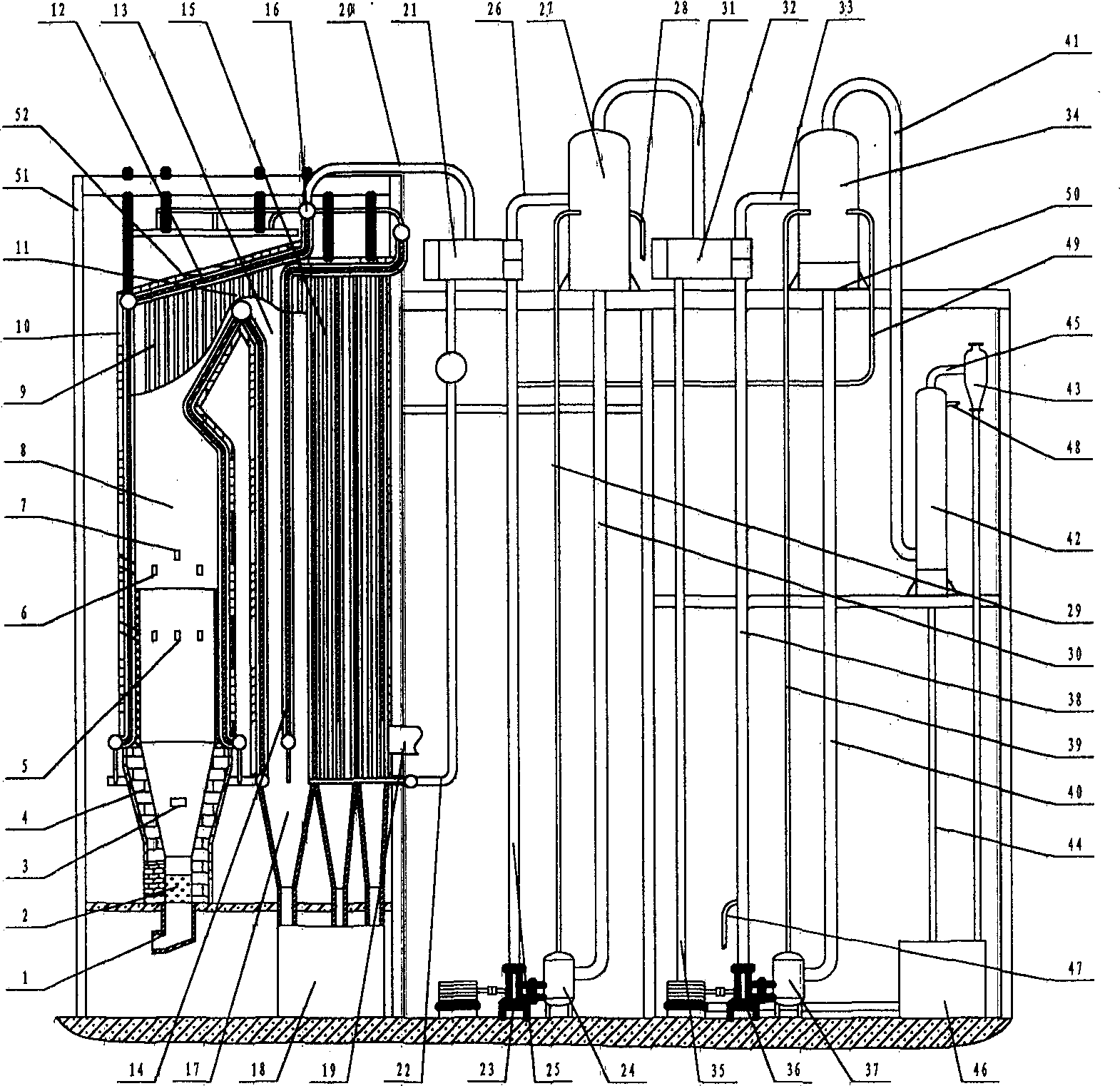

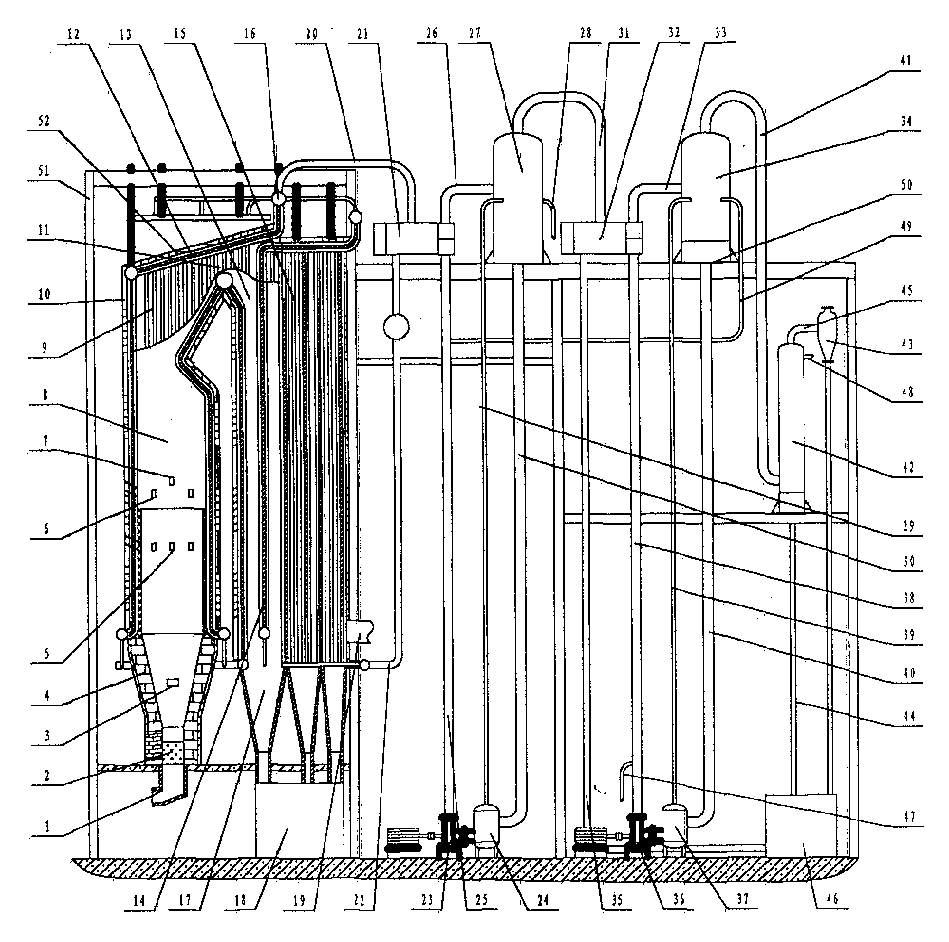

[0007] according to figure 1 As shown, the specific embodiment of the present invention is as follows. The combustion furnace 52 and the enrichment device 50 are integrated, and the combustion chamber 8 of the combustion furnace 52 is provided with an inverted conical adiabatic combustion section 4 made of refractory material and a water cooling section 9 with a heat pipe water cooling structure 12 as a heating surface; The bottom of the adiabatic combustion section 4 is provided with a fluidized bed 2, and below the fluidized bed 2 is an air box 1; the ignition fuel supply port 3 is provided on the cone section of the adiabatic combustion section 4; The position of the upper straight section near the outlet is inclined to the bottom fluidized bed at an angle of 15 to 30 degrees to the horizontal; the water cooling section 9 is set above the adiabatic combustion section 4, and the lower part of the water cooling section 9 is provided with a tertiary tuyere 6 and a waste liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com