A device and method for back-spraying denitrification of leachate from a garbage incinerator

A technology for landfill leachate and waste incinerator, which is applied in the field of denitrification treatment technology, can solve problems such as failure to form, and achieve the effects of low price, simple and easy method, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

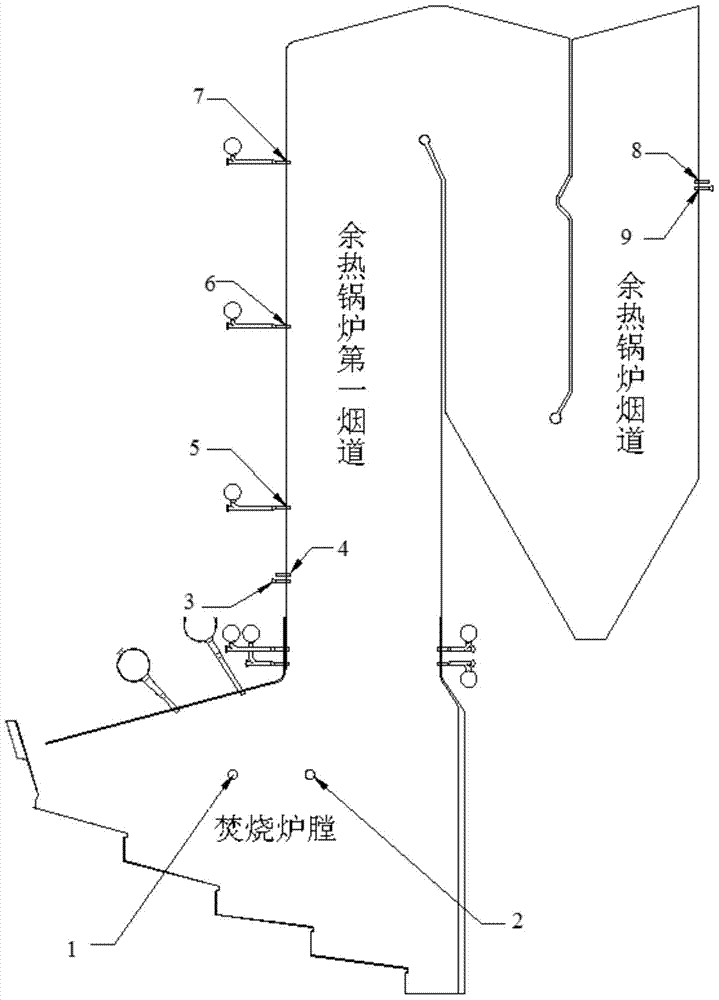

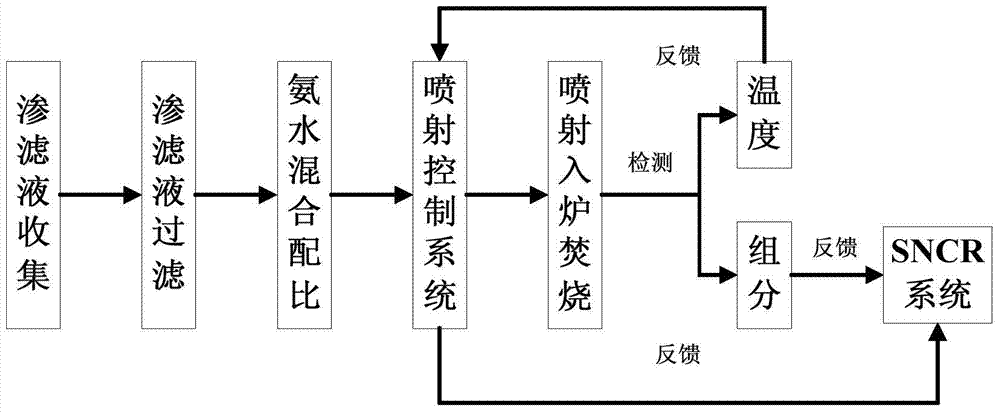

[0034] Such as Figures 1 to 3 shown. The leachate back-spray denitrification device of the garbage incinerator of the present invention includes a leachate injection control system, an SNCR spray gun control system, an array of garbage leachate spray guns arranged on the wall of the incinerator chamber, and a thermocouple 3 arranged in the first flue of the waste heat boiler And infrared thermometer 4, set the SNCR spray gun array at the first flue of the waste heat boiler, set the NO at the outlet of the waste heat boiler flue X Sensor 8 and O 2 sensor 9;

[0035] The SNCR spray gun control system and leachate injection control system, NO X Sensor 8 and O 2 Sensor 9 is connected.

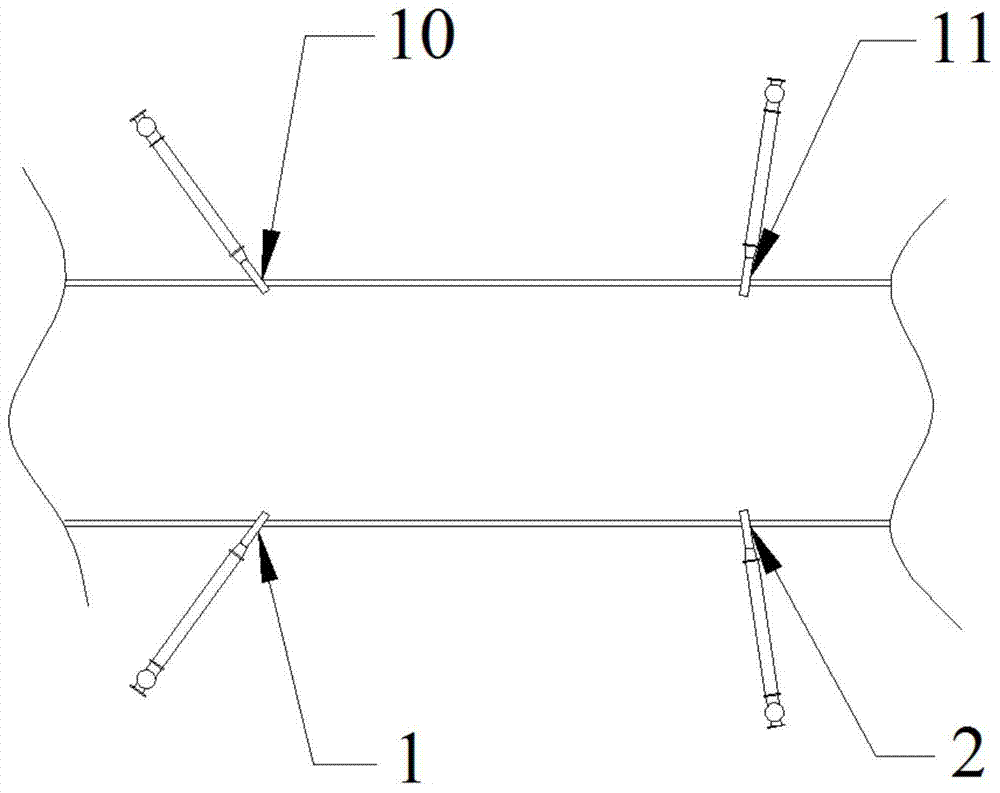

[0036]The landfill leachate spray gun array is composed of 4 spray guns, namely A spray gun 1, B spray gun 10, C spray gun 2 and D spray gun 11, the flow rate of each spray gun is independently controlled, and the height is located at 3 / 5 of the furnace height; Among these 4 spray guns, A sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com