Pure-burning biomass environment-friendly circulating fluidized bed high-temperature and high-pressure steam boiler

A circulating fluidized bed, high temperature and high pressure technology, used in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of narrow fuel range, high pollution emissions, low combustion efficiency, etc., to achieve a large combustion share, prevent smoke The effect of gas back channeling and raising the height of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

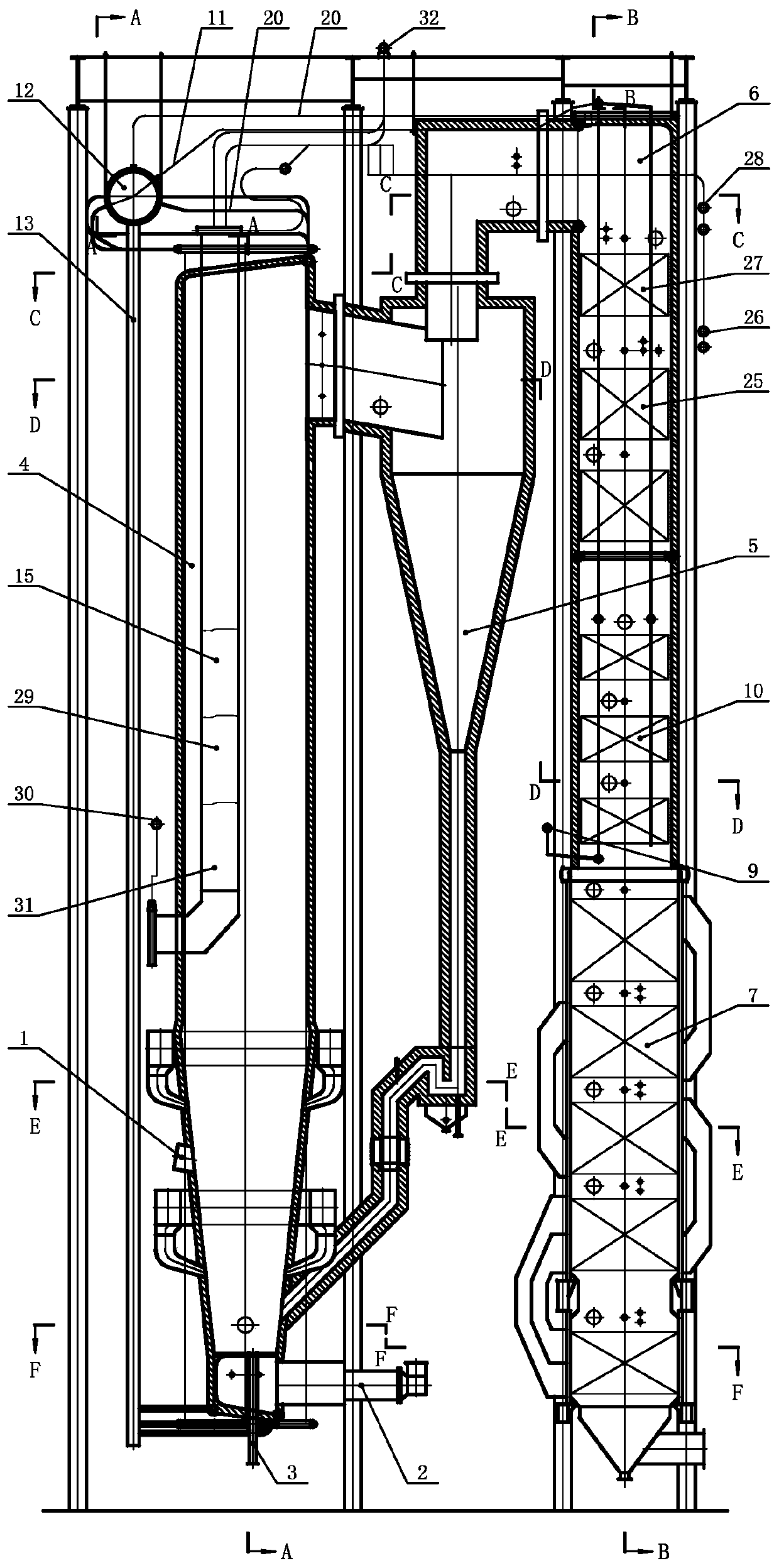

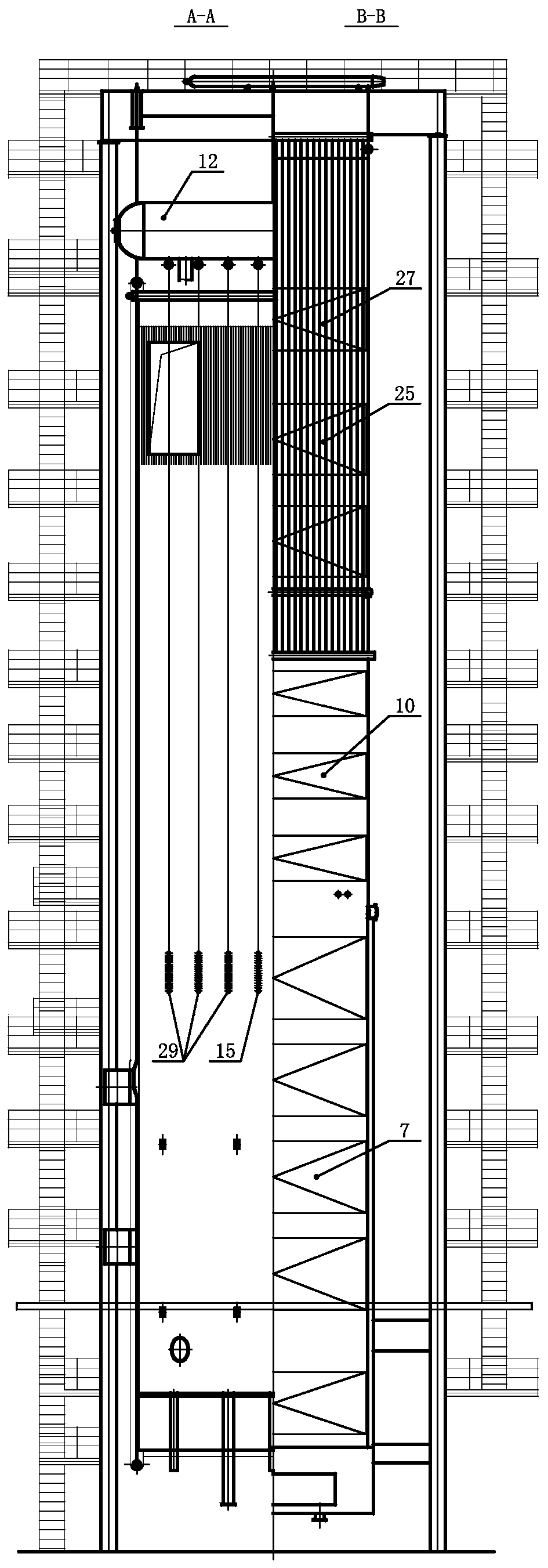

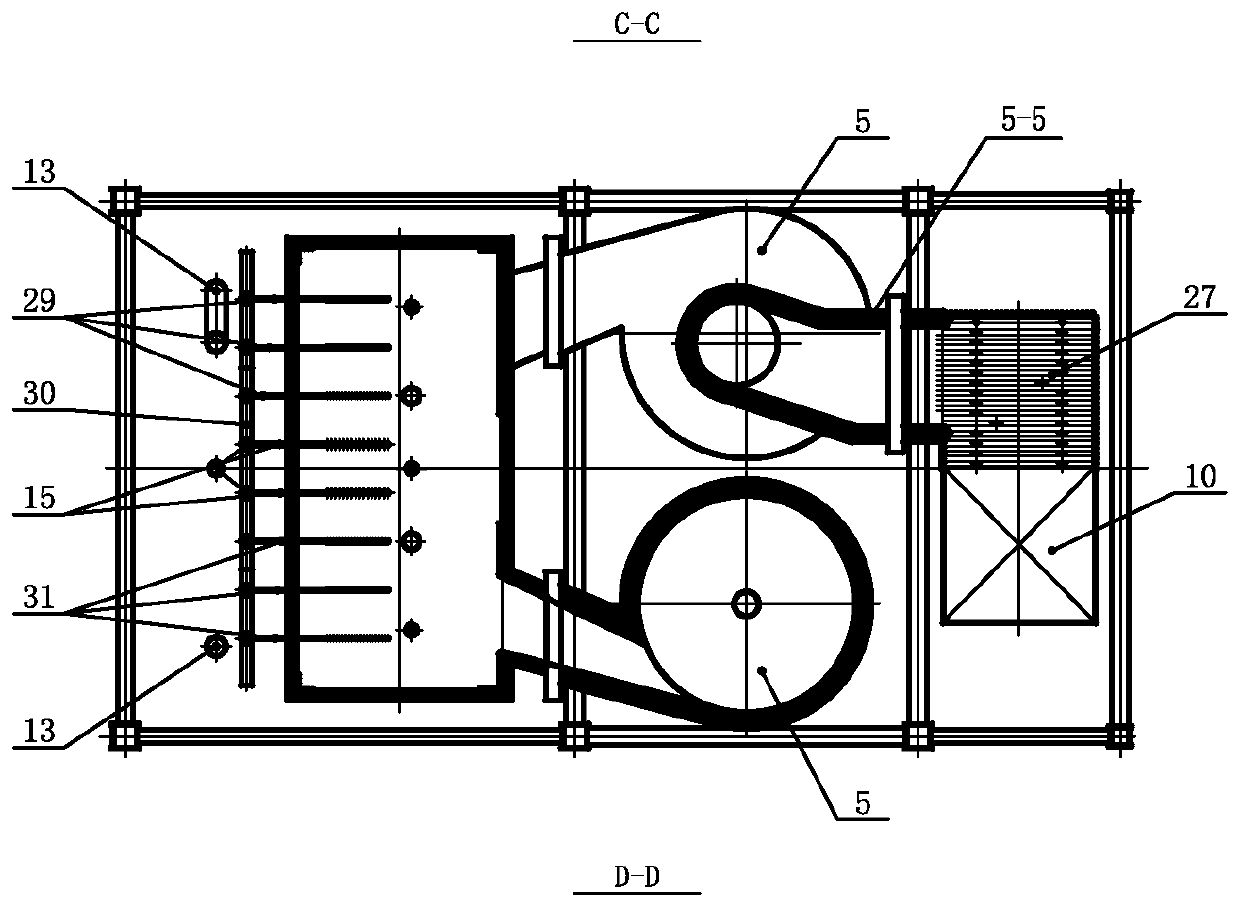

[0047] Specific implementation mode one: as Figure 1-11 As shown, the purely burning biomass environment-friendly circulating fluidized bed high-temperature and high-pressure steam boiler in this embodiment includes a purely burning biomass feeding system 1, an ignition device 2, an ash discharge device 3, a furnace 4, a separation and return system 5, Wall cladding superheater 6, air preheater 7, environmental protection interface 8, water supply header 9, economizer 10, water supply distribution pipe 11, drum 12, concentrated descending pipe 13, water cooling screen descending pipe 14, water cooling screen 15, Water-cooled screen outlet pipe 16, water-cooled steam guide pipe 20, steam outlet pipe 21, side wall 22, front wall 23, rear wall 24, low-temperature superheater 25, primary spray desuperheater 26, medium-temperature superheater 27 , two-stage water spray desuperheater 28, medium temperature screen superheater 29, three-stage water spray desuperheater 30, high temper...

specific Embodiment approach 2

[0075] Specific implementation mode two: as figure 1 , Figure 5 with Figure 7 As shown, the cross-section of the feeding interface 1-1 in this embodiment is rectangular, the cross-sectional size of the feeding interface 1-1 is 800x800mm, the feeding interface 1-1 is set downwardly, and the downward inclination angle a of the feeding interface is 10-15°, the zero pressure point is set between the feeding interface 1-1 and the lower secondary air outlet 1-2.

[0076] This design is convenient for feeding and avoiding accumulation; the zero pressure point is between the biomass feed port 1-1 and the next secondary air port 1-2, which realizes negative pressure feeding of biomass, and negative pressure is beneficial to lighter biomass Feeding, because the density of biomass is small, positive pressure feeding is easy to cause external spray and pollute the environment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0077] Specific implementation mode three: as figure 1 , Figure 5 with Figure 7 As shown, the quantity of the ash discharge pipe 3-1 in this embodiment is three, the diameter of the ash discharge pipe 3-1 is Φ273mm, the quantity of the slag discharge pipe 3-2 is two, and the diameter of the slag discharge pipe 3-2 is Φ325mm.

[0078] With this design, the ash discharge pipe 5-1 adopts a Φ273mm diameter pipe to discharge the fine ash after biomass combustion, and adopts a small amount of multiple rows to avoid local ash coking to form slag; the slag discharge pipe 5-2 adopts a Φ325mm diameter pipe, large The pipe diameter can smoothly discharge small slag lumps and unburned impurities and sundries that enter the furnace with biomass, which can prevent slag blocking and effectively avoid accidental shutdown due to poor slag discharge. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com