Medical waste incinerator applied with oxygen-enriched combustion technology

A medical waste and oxygen-enriched combustion technology, applied in the direction of incinerators, combustion types, combustion equipment, etc., can solve the problems that it is difficult to ensure the temperature of the secondary combustion chamber, and the combustion air volume cannot guarantee the temperature of 1100 ° C, so as to weaken the generation environment and avoid residues. The presence of carbon and the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below in conjunction with accompanying drawing.

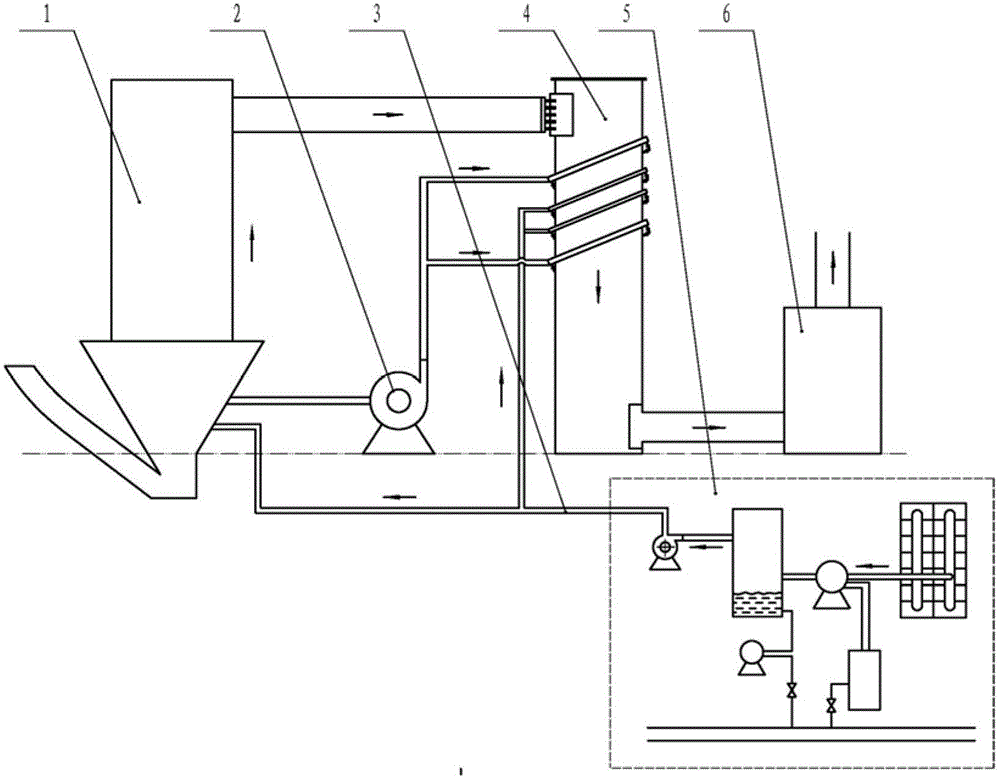

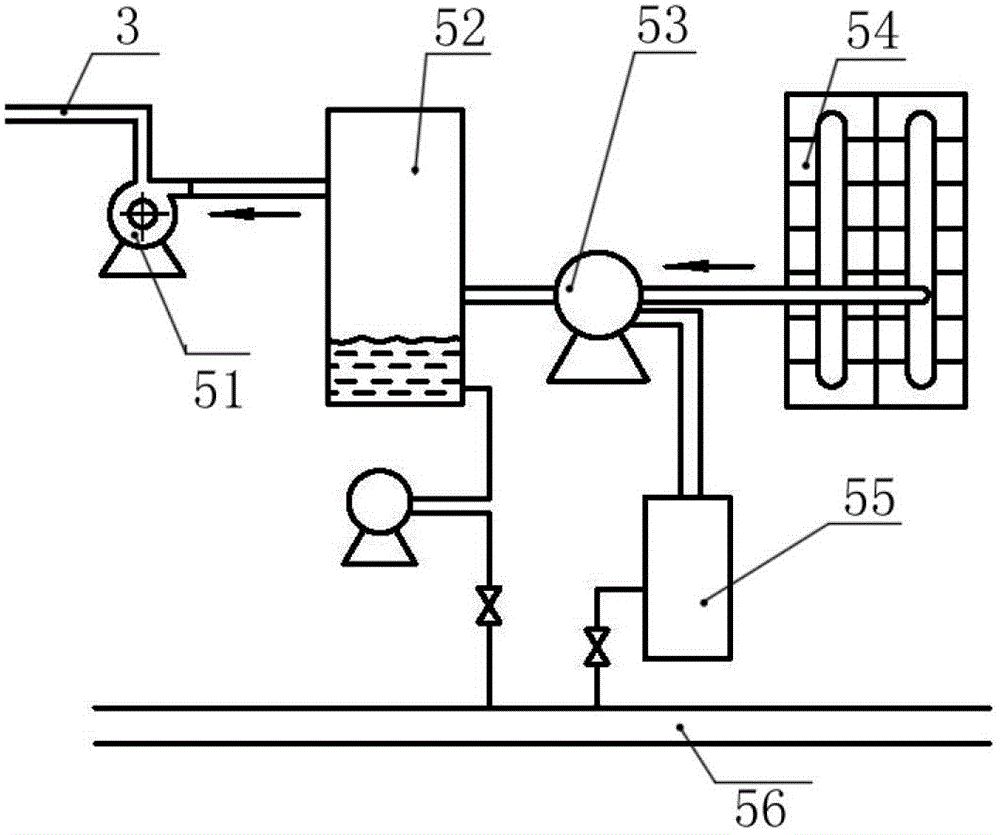

[0056] like Figure 1-7 As shown, the medical waste incinerator using oxygen-enriched combustion technology in the present invention includes a medical waste incinerator main body 1, a second combustion chamber main body 4, a combustion-supporting fan 2, an oxygen-enriched air supply system, and a flue gas tail treatment system 6; wherein:

[0057] The combustible components in the medical waste are decomposed into combustible gas (flue gas), and the combustible gas (flue gas) enters the second combustion chamber main body 4 through the flue provided above the incinerator main body 1 for combustion; at the flue gas outlet of the incinerator main body 1 Flue gas temperature ≥ 850 ℃ or more.

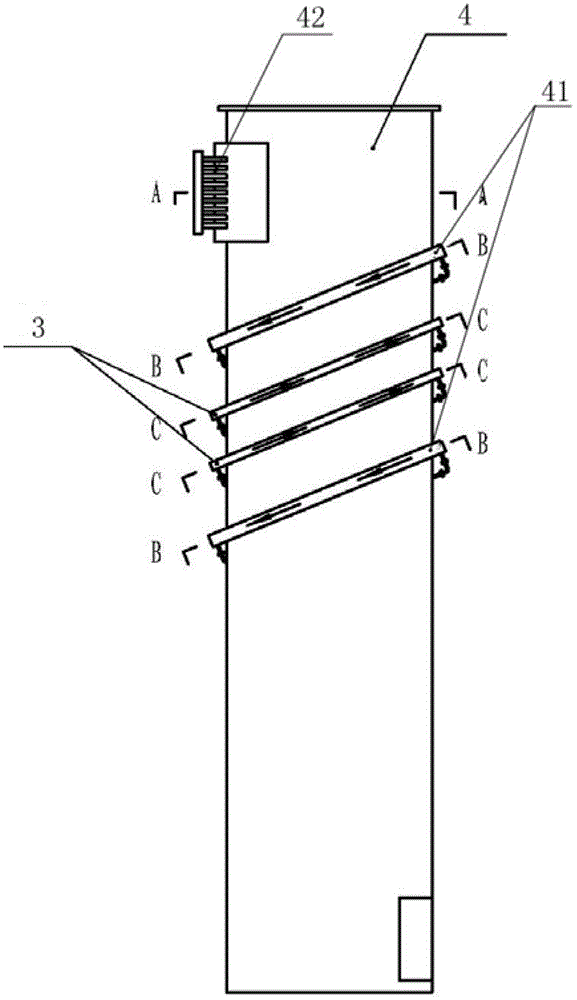

[0058] The combustion temperature in the main body 4 of the second combustion chamber is above 950°C-1000°C, where the dioxins are decomposed and burned; The air distribution pipe 42, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com