A high-efficiency production process of high aluminum alloy structural round steel

A production process and technology of aluminum alloy, applied in the direction of manufacturing converters, etc., can solve the problems of aluminum not reaching the ideal, aluminum is not easy to add, easy to block the nozzle, etc., to achieve stable aluminum yield, high aluminum absorption rate, avoidance of low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

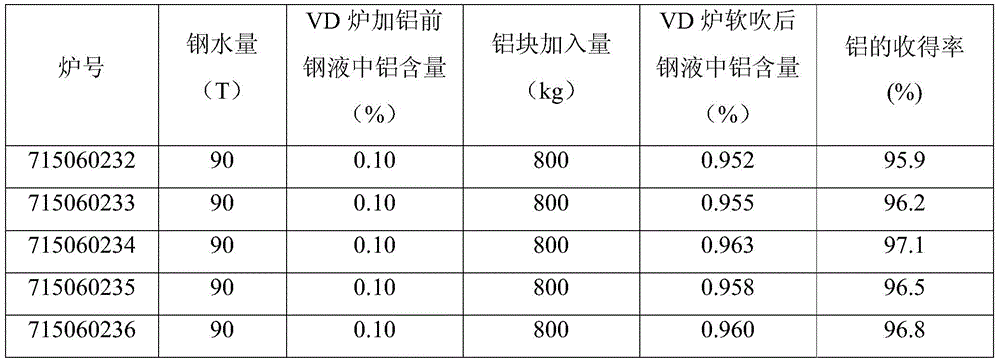

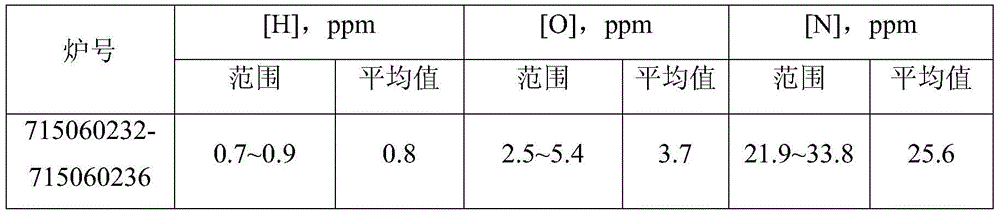

Examples

Embodiment 1

[0033] Embodiment 1 (stove number 715060232)

[0034] (1) Converter smelting process

[0035] Converter smelting adopts high-quality molten iron. Among them, the mass content requirements of components in molten iron entering the furnace are: Si: 0.43%, P: 0.091%, S: 0.014%, and the temperature of molten iron entering the furnace is T = 1315°C.

[0036] Converter smelting controls tapping end point [C]=0.25%, end point [P]=0.006%, tapping temperature is 1650°C, the tapping process adopts sliding plate slag blocking operation, tapping time is 4 minutes, tapping 1 / 4 of the time in sequence Add 100Kg of calcium carbide deoxidizer and 180Kg of aluminum block;

[0037] (2) LF refining process

[0038] The ladle of the LF refining furnace is covered to ensure that the LF refining furnace is well sealed, and the furnace is a reducing atmosphere. Refining adds 50kg of aluminum particles / furnace and 60kg of calcium carbide / furnace to deoxidize the steel slag interface. In the early a...

Embodiment 2

[0047] Embodiment 2 (stove number 715060233)

[0048] This furnace is a continuous pouring furnace, the temperature of the hanging bag after soft blowing is set to 1565°C, the degree of superheat is 38°C, the casting speed is 0.76m / min, and the rest of the operations are the same as in Example 1.

Embodiment 3

[0049] Embodiment 3 (stove number 715060234)

[0050] Requirements for the mass content of the components in the molten iron: Si: 0.46%, P: 0.089%, S: 0.015%, the temperature of the molten iron in the furnace is T = 1320°C, the furnace is continuous pouring, and the temperature of the hanging ladle after soft blowing is set to 1565°C, the degree of superheat is 38°C, the casting speed is 0.75m / min, and the other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com