Device guarantee regenerative thermal oxidizer (GRTO) capable of treating inflammable and explosive industrial organic waste gas more safely

A flammable, explosive, organic waste gas technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of high energy consumption, poor safety and stability, etc., achieve system safety, facilitate switching, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

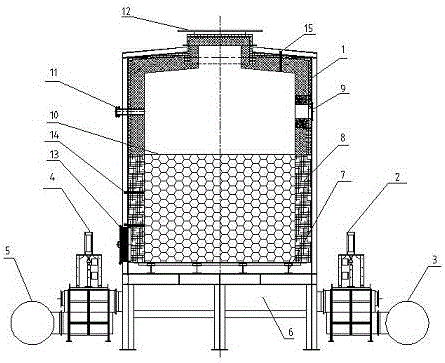

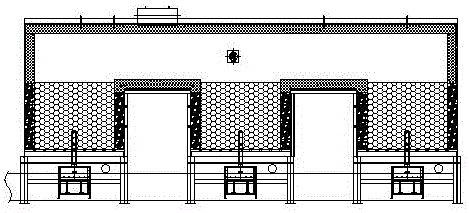

[0024] Please refer to figure 1 , figure 2 , the implementation of the device GRTO of the present invention will be described in detail.

[0025] Before (9) is ignited, fresh air should be used to purge the whole system to clean up the organic waste gas or diesel oil remaining in (10) and the furnace to prevent explosion during ignition. The time of purging is hardware design, and the hardware is linked with the flame control system. If the purging is not completed, the ignition cannot be carried out to ensure the safety of the system. Fresh air enters one of (2) from (3), and the other two are closed, entering (10) and purging the furnace. Then discharge (4) and (5) into the atmosphere, switch every 3 minutes, and purge for about 15 minutes.

[0026] After the purging is completed, (9) ignite and heat up, keeping it at 3 degrees per minute, and the heating time is about 3 to 4 hours, so that the temperature of (10) rises slowly. Brick cracking may shorten the life of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com