A compact, small-capacity, and high-output biomass pellet boiler

A biomass particle and small-capacity technology, which is applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of a large amount of dense smoke, high exhaust temperature, incomplete combustion, etc., and achieve complete heat transfer and exhaust The effect of low exhaust gas temperature and reduction of insulation thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

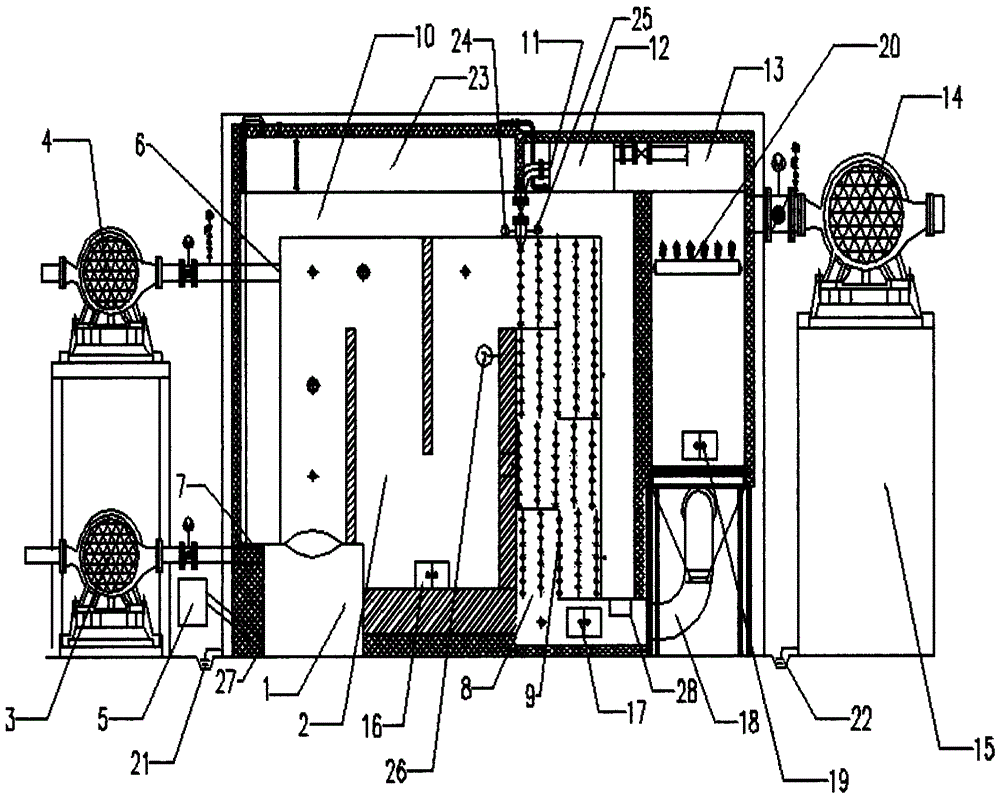

[0010] The invention can solve the problems of poor heat transfer and incomplete combustion of existing biomass pellet boilers, save energy and reduce emissions, and operate safely and stably; it can be used as both a hot water boiler and a steam boiler, and the rated evaporation can reach 1000kg when used as a steam boiler / h or more; the boiler adopts a combined machine with a compact structure to minimize its volume

[0011] A compact, small-capacity, and high-efficiency biomass pellet boiler includes an intelligent control system, a combustion chamber (2), a burner (1), a flue gas outlet (18), a primary fan (3), a secondary fan (4), and an induced draft fan (14), deaerator (10), heat exchange chamber (8), bag filter (20), steam-water separator (12), sub-cylinder (13), boiler water purifier (15); The burner (1) is set on the lower side of the chamber (2), the primary air inlet and the feed port (27) are set on the burner (1), and the steam-water separator is set on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com