Combustion recycling system for gasified fly ash of fluidized bed

A technology of fluidized bed gasification and fly ash, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, transportation of non-flammable liquid/gas, etc. It can solve the problems of difficult burnout, high ash content and ignition temperature, Combustion temperature can not meet the problem, to achieve the effect of solving utilization problems, reducing fuel consumption and nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

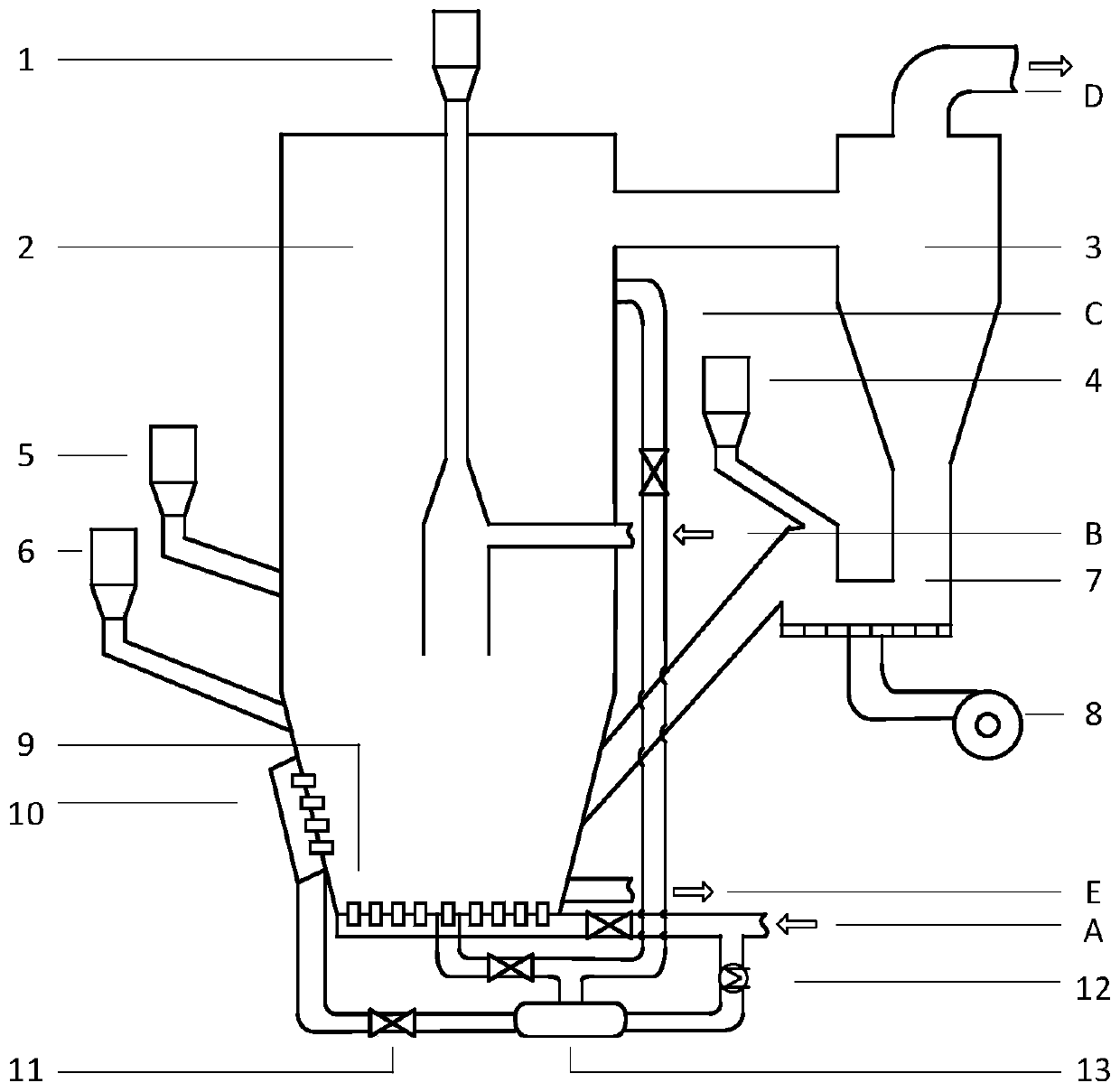

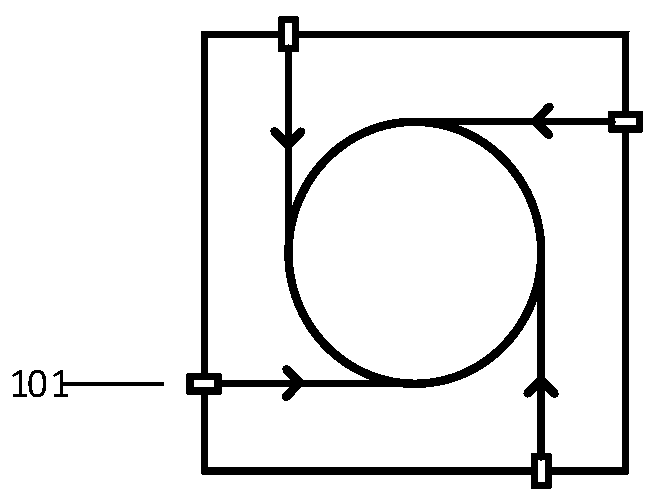

[0026] like figure 1 and figure 2 As shown, a combustion system for fluidized bed gasification fly ash provided by the present invention includes a first fuel bin 1, a furnace 2, a cyclone separator 3, a gasification fly ash bin 4, a limestone bin 5, a second fuel bin Bin 6, ash hopper 7, blower 8, bottom air distribution plate 9, bottom side air distribution plate 10, flow valve 11, air compressor 12 and air film separator 13.

[0027] Among them, the first fuel tank 1 is arranged on the upper part of the furnace 2, and is transported to the junction of the dense-phase area and the dilute-phase area of the furnace through the expanding pipeline. The position of the cyclone separator 3 is connected to the outlet of the furnace 2, the outlet of the cyclone separator 3 is connected to the inlet of the ash hopper 7, the outlet of the gasification fly ash bin 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com